PC material with super ceramic texture and preparation method thereof

A technology of texture and ceramics, which is applied in the field of ultra-ceramic texture PC materials and its preparation, can solve the problem of the application of high-refraction mass-produced glass beads and high-reflectivity silver-white pearl powder, and the methods of improving ceramic texture and recycling. Difficulty and other problems, to achieve the effect of improving gloss, highlighting impact resistance, and good reflective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

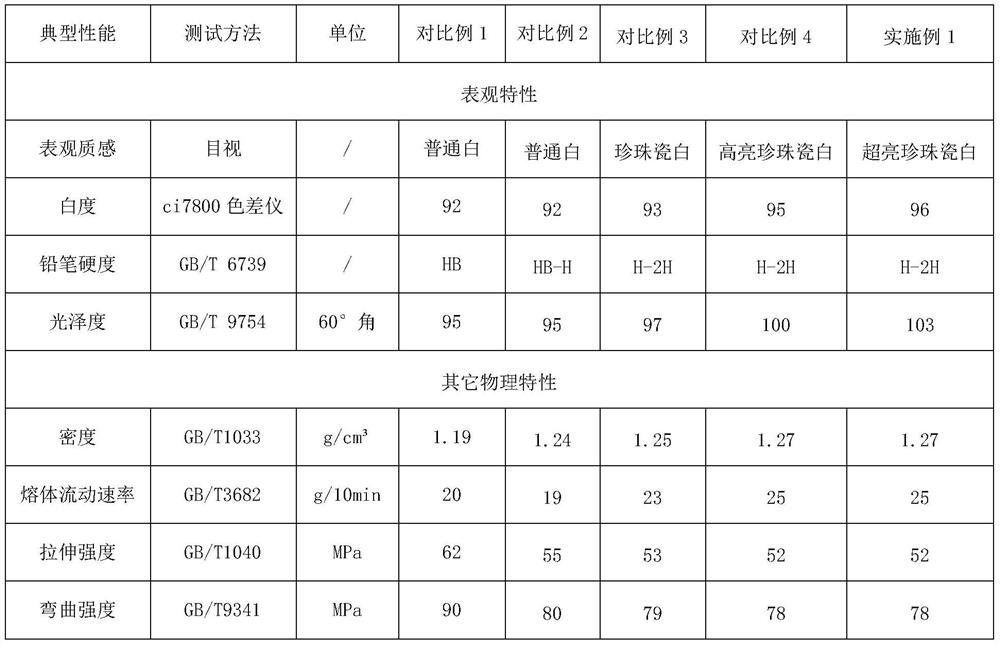

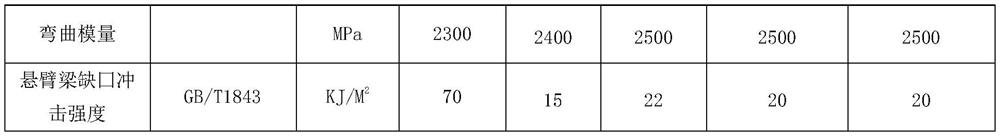

Examples

Embodiment 1

[0033]A PC material with super ceramic texture, comprising the following raw materials in parts by weight: 55 parts of polycarbonate, 32 parts of polymethyl methacrylate, 3 parts of compatibilizer, 8 parts of ceramic powder, 2 parts of glass beads, modified 0.3 parts of pearl powder, 0.8 parts of titanium dioxide, 0.3 parts of light stabilizer, 0.3 parts of antioxidant, and 0.5 parts of lubricant.

[0034] The preparation method of superceramic texture PC material comprises the following steps:

[0035] S1. Weigh the raw materials by weight, add polycarbonate, polymethyl methacrylate, and compatibilizer into the high-speed mixer, and mix the mixture for 5-7 minutes under the protection of nitrogen, and the mixing temperature is 60-75°C;

[0036] S2. Add light stabilizer, antioxidant and lubricant to the material obtained in step S1, mix the materials for 10-15 minutes under the protection of nitrogen, and the mixing temperature is 60-75 °C;

[0037] S3. Add ceramic powder, gl...

Embodiment 2

[0040] A super ceramic texture PC material, comprising the following raw materials in parts by weight: 50 parts of polycarbonate, 30 parts of polymethyl methacrylate, 2 parts of compatibilizer, 6 parts of ceramic powder, 1 part of glass beads, modified 0.2 parts of pearl powder, 0.5 parts of titanium dioxide, 0.2 parts of light stabilizer, 0.2 parts of antioxidant, and 0.3 parts of lubricant.

[0041] The preparation method of super ceramic texture PC material is the same as that in Example 1.

Embodiment 3

[0043] A super ceramic texture PC material, comprising the following raw materials in parts by weight: 60 parts of polycarbonate, 35 parts of polymethyl methacrylate, 4 parts of compatibilizer, 10 parts of ceramic powder, 3 parts of glass beads, modified 0.5 part of pearl powder, 1 part of titanium dioxide, 0.5 part of light stabilizer, 0.5 part of antioxidant, and 1 part of lubricant.

[0044] The preparation method of super ceramic texture PC material is the same as that in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com