A kind of organosilicon material and its preparation method and application

An organic silicon and nano-silicon carbide technology, applied in the field of materials, can solve the problems of poor visual effect, inability to meet the needs of use, limited weather resistance and heat dissipation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

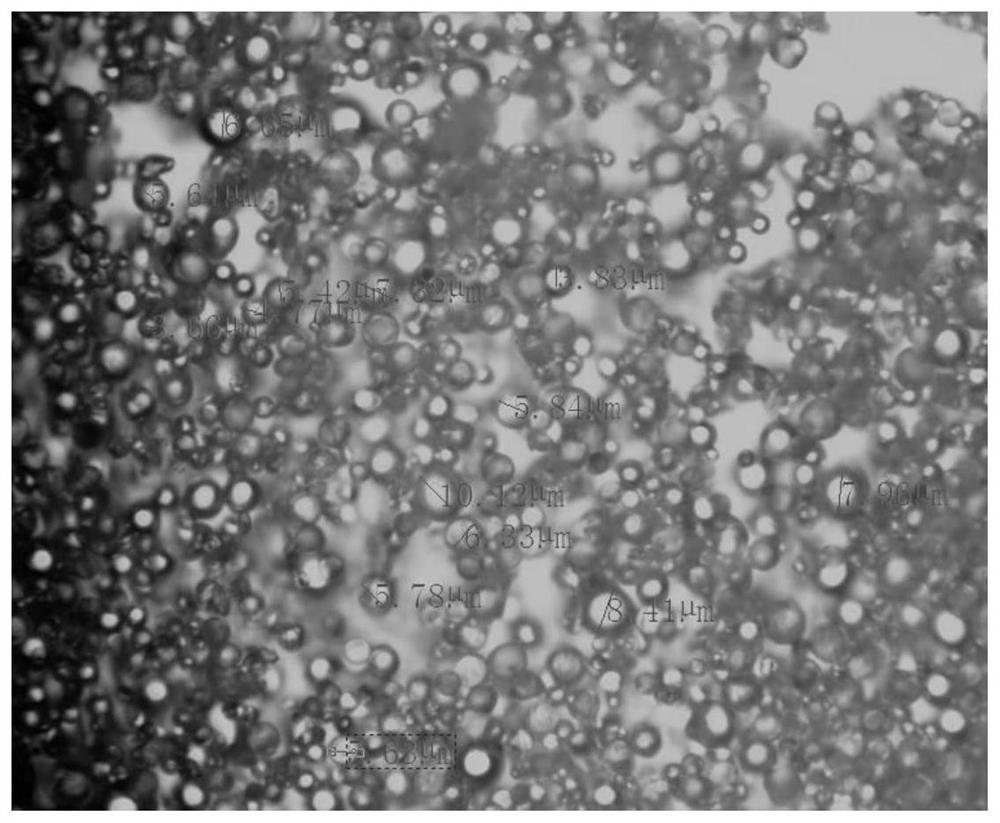

Image

Examples

preparation example Construction

[0028] The embodiment of the present invention also provides a preparation method of the organosilicon material, comprising:

[0029] The modified nano-silicon carbide is added into the organic silicon mixture in an amount of 3-8% by weight, subjected to planetary dispersion and mixing, and degassed to obtain the product. The dispersing and defoaming processes are conventional means, and will not be described in detail here.

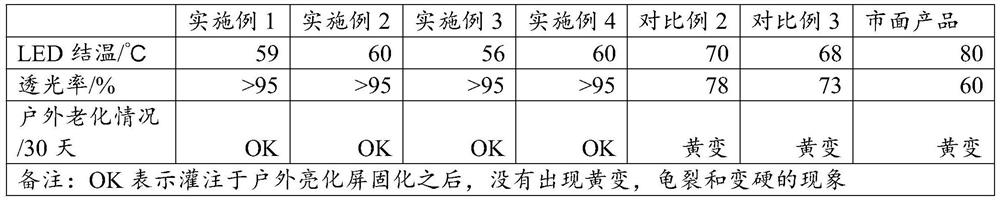

[0030] The embodiment of the present invention also provides an application of the organic silicon material in an outdoor brightening screen.

[0031] In the embodiment of the present invention, according to the construction requirements of the LED lighting screen, the screen body and the curtain wall glass can be pre-laminated and assembled using the method of flat scraping / spraying, or the screen body can be assembled on the completed curtain wall After four weeks of pre-curing, it is then poured into the fit.

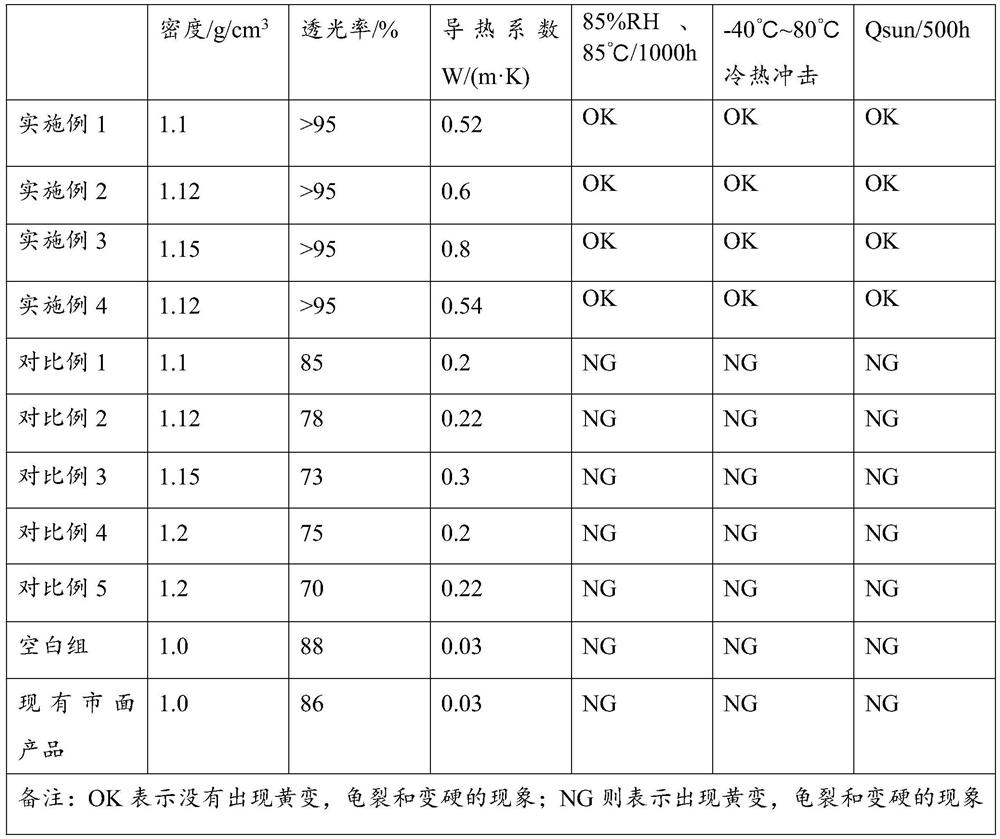

Embodiment 1

[0034] The nano-silicon carbide powder body that 2kg surface coats silicon dioxide film imports in the fluidized bed, then adds the tetramethyldivinyl disilazane of 40g, blows into compressed air (nitrogen) according to the flow velocity of 30mL / min as The carrier gas is rapidly heated to 150°C, the boiling effect is partial boiling, and the reaction is carried out for 3 hours, then the carrier gas is stopped, and the gas inside is evacuated to obtain the modified nano-silicon carbide 1.

[0035] The modified nano-silicon carbide 1 is added to the organic silicon mixture according to the addition amount of 3% (the organic silicon mixture is formed by directly mixing the raw materials in the following parts by weight: 65 parts of vinyl silicone oil, 15 parts of hydrogen-containing silicone oil, 7 parts of long-chain alkyl silicone oil and 10 parts of vinyl silicone resin), after planetary dispersion mixing, defoaming and packaging, to obtain.

Embodiment 2

[0037] Introduce 2kg of nano-silicon carbide powder coated with a silicon dioxide film on the surface into the fluidized bed, then add 40g of tetramethyldivinyldisilazane, and blow into compressed air (argon) at a flow rate of 70mL / min As a carrier gas, it is rapidly heated to 170°C, the boiling effect is convective boiling, and the reaction is carried out for 4 hours, then the carrier gas is stopped, and the gas inside is evacuated to obtain the modified nano-silicon carbide 2.

[0038] The modified nano-silicon carbide 2 is added to the organic silicon mixture according to the addition amount of 5% (the organic silicon mixture is formed by directly mixing the raw materials in the following parts by weight: 65 parts of vinyl silicone oil, 15 parts of hydrogen-containing silicone oil, 7 parts of long-chain alkyl silicone oil and 8 parts of vinyl silicone resin), after planetary dispersion mixing, defoaming and packaging, to obtain.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com