Flexible film capacitor with high energy storage density and preparation method

A high energy storage density, film capacitor technology, applied in the direction of film/thick film capacitors, multilayer capacitors, fixed capacitor electrodes, etc. Reduce the energy storage density of capacitors and other issues to achieve the effect of improving the quality of the contact interface, easy mass production, and high capacitance density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

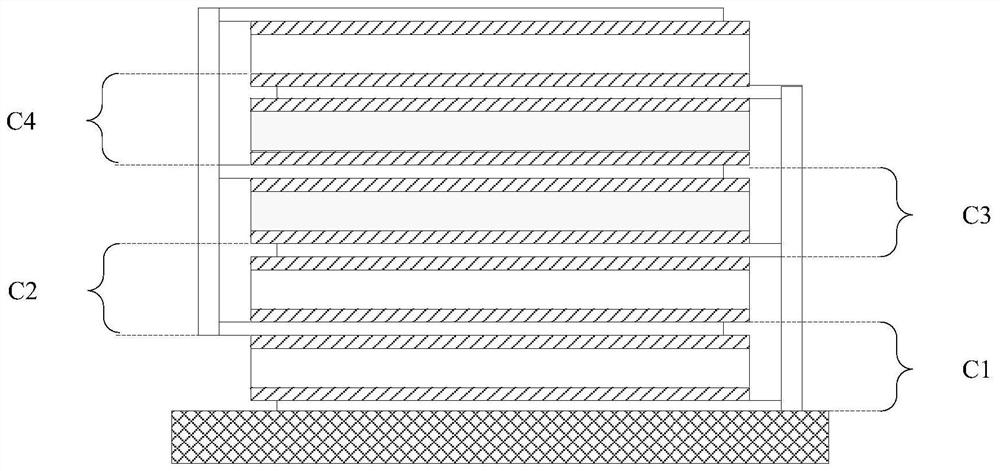

[0052] A method for preparing a flexible film capacitor with high energy storage density, the specific steps are as follows:

[0053] Select a flexible polymer as the substrate, and then sequentially prepare one or more film capacitor layers on the flexible polymer substrate 1 after surface treatment such as cutting, ultrasonic cleaning with acetone and absolute ethanol, and drying in an oven at 100°C;

[0054] Wherein, the preparation of film capacitor layer comprises the following steps:

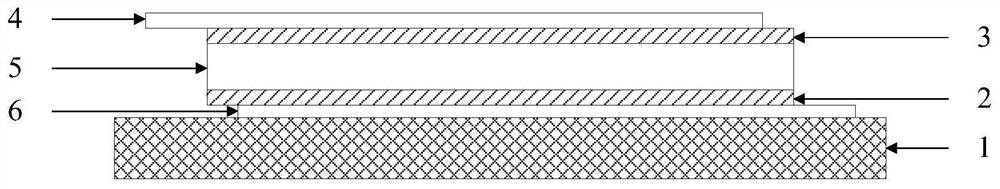

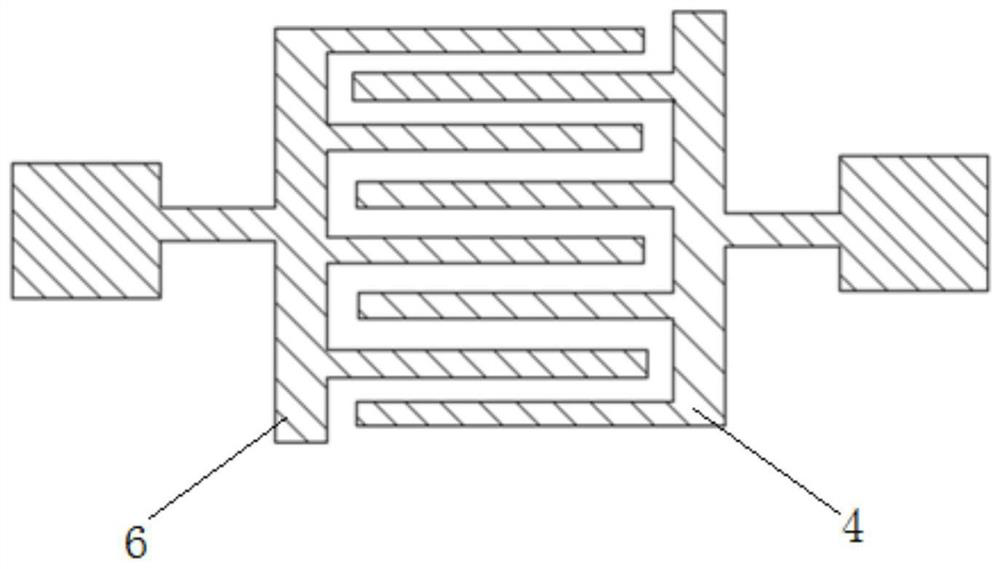

[0055] Step 1, preparation of lower transparent electrode layer 6

[0056] Firstly, an electrode pattern is prepared on the flexible polymer substrate 1 by using a lift-off stripping process;

[0057] Then, at room temperature, a layer of lower transparent electrode layer 6 with a thickness of 150-200 nm is deposited on the prepared electrode pattern by magnetron sputtering or thermal evaporation coating method;

[0058] Step 2, preparation of lower modification layer 2

[0059] At room...

Embodiment 1

[0076] Select a flexible polymer as the substrate, and then sequentially prepare one or more film capacitor layers on the flexible polymer substrate 1 after surface treatment such as cutting, ultrasonic cleaning with acetone and absolute ethanol, and drying in an oven at 100°C;

[0077] Wherein, the preparation of film capacitor layer comprises the following steps:

[0078] Step 1, preparation of lower transparent electrode layer 6

[0079] Firstly, an electrode pattern is prepared on the flexible polymer substrate 1 by using a lift-off stripping process;

[0080] Then, at room temperature, a lower transparent electrode layer 6 with a thickness of 150 nm is deposited on the prepared electrode pattern by magnetron sputtering or thermal evaporation coating method;

[0081] Step 2, preparation of lower modification layer 2

[0082] At room temperature, use WS 2 For the target material, a lower modification layer 2 with a thickness of 10-20 nm is deposited on the basis of the l...

Embodiment 2

[0092] Select a flexible polymer as the substrate, and then sequentially prepare one or more film capacitor layers on the flexible polymer substrate 1 after surface treatment such as cutting, ultrasonic cleaning with acetone and absolute ethanol, and drying in an oven at 100°C;

[0093] Wherein, the preparation of film capacitor layer comprises the following steps:

[0094] Step 1, preparation of lower transparent electrode layer 6

[0095] Firstly, an electrode pattern is prepared on the flexible polymer substrate 1 by using a lift-off stripping process;

[0096] Then, at room temperature, a lower transparent electrode layer 6 with a thickness of 150 nm is deposited on the prepared electrode pattern by magnetron sputtering or thermal evaporation coating method;

[0097] Step 2, preparation of lower modification layer 2

[0098] At room temperature, use WS 2 For the target material, a lower modification layer 2 with a thickness of 10 nm is deposited on the basis of the lowe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com