Electrode material with ultrafine MoO2 nano-particles uniformly bridged inside flaky carbon matrix, as well as preparation method and application of electrode material

A nanoparticle and electrode material technology, applied in the field of nanomaterials and electrochemistry, can solve the problems of unsatisfactory cycle performance and life, poor dynamic volume expansion of lithium deintercalation, and achieve excellent electron/ion conductivity and structural stability. , reduce volume expansion, improve the effect of conduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The preparation method of the electrode material uniformly bridged with ultrafine MoO2 nanoparticles inside the sheet-like carbon matrix comprises the following steps:

[0031] 1) Mix 0.96g Mo powder and add 20mL H 2 o 2 and 20mL H 2 O mixed solution, stirred for 12h;

[0032] 2) Transfer the solution obtained in step 1) into a 100mL reactor and heat at 180°C for 24h, take out the reactor, and cool to room temperature naturally to obtain MoO 3 Nanobelt solution;

[0033]3) Add 2 mL of the product obtained in step 2) and 0.3 g of dopamine hydrochloride to a solution of 0.1214 g of tris-hydroxymethylaminomethane dissolved in 100 mL of deionized water, stir for 4 hours, and wash with deionized water and absolute ethanol three times respectively , dried in an oven at 80°C to obtain a flower-like Mo-polydopamine composite (Mo-PDA);

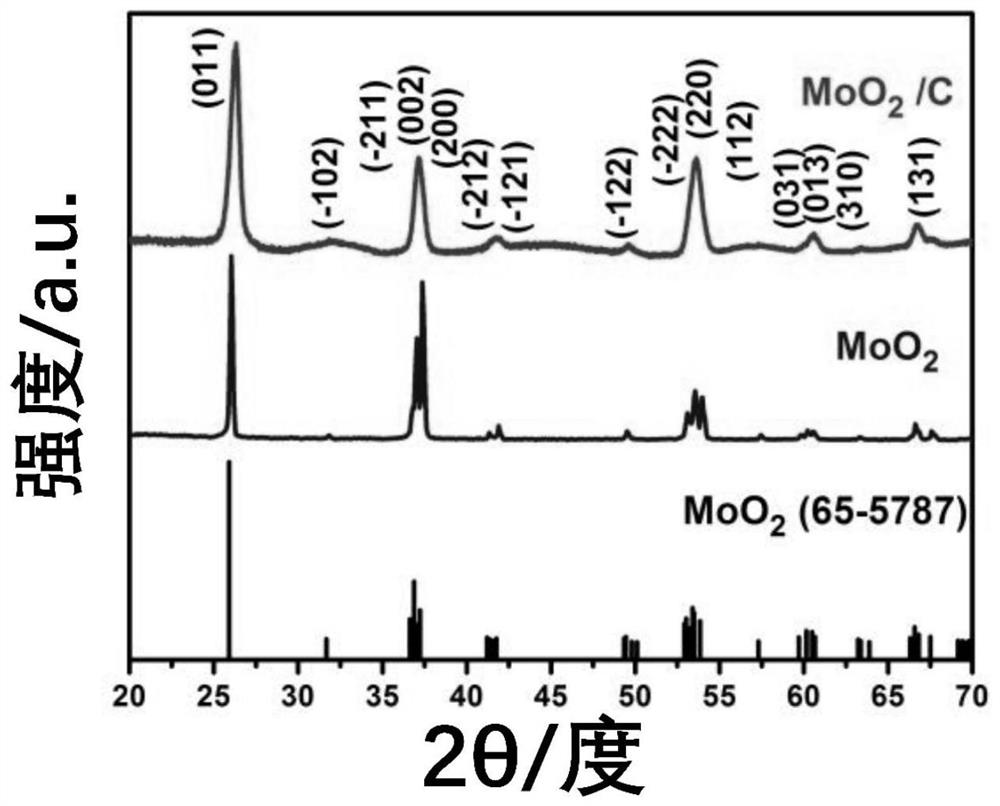

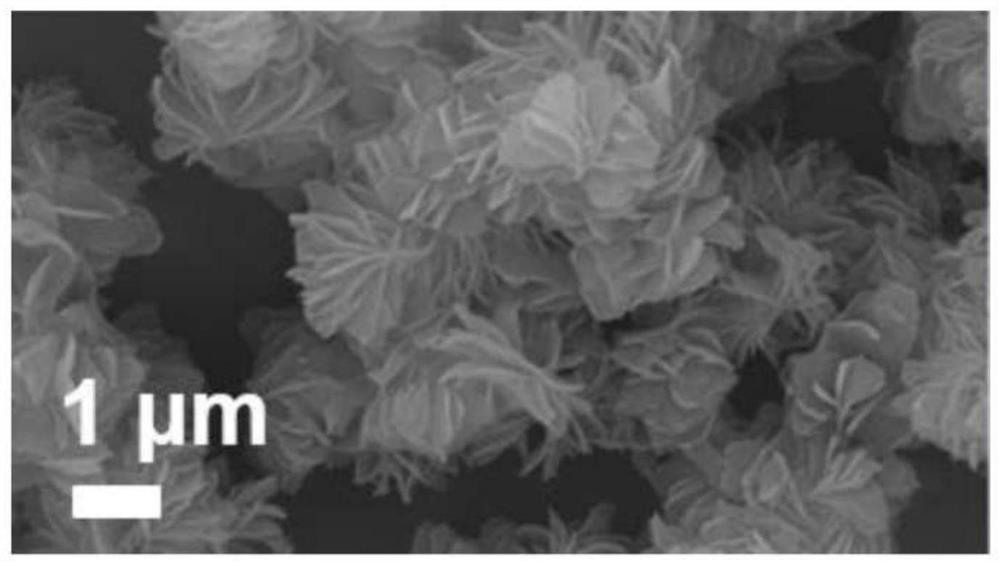

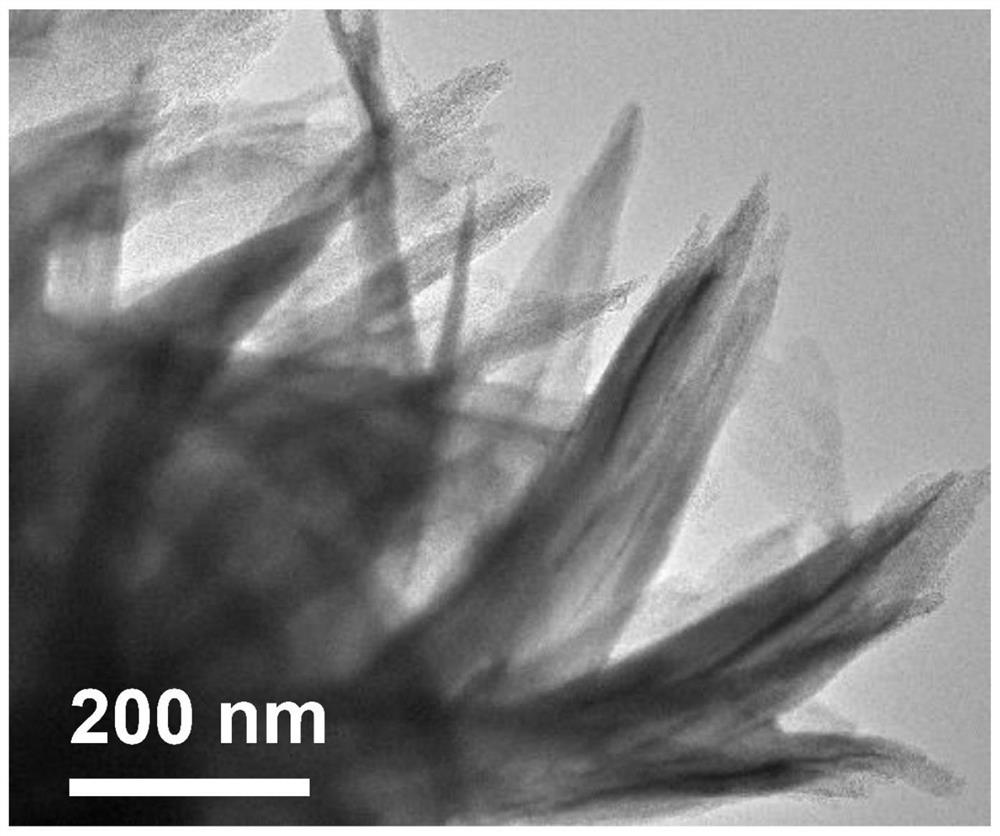

[0034] 4) The product obtained in step 3) is placed in a tube furnace and sintered at 800°C for 2 hours in an Ar atmosphere to obtain unif...

Embodiment 2

[0040] 1) Mix 1.5g Mo powder and add 30mL H 2 o 2 and 30mL H 2 In the mixed solution of O, stir for 18h;

[0041] 2) Transfer the solution obtained in step 1) into a 100mL reactor and heat at 200°C for 24h, take out the reactor, and cool to room temperature naturally to obtain MoO 3 Nanobelt solution;

[0042] 3) Add 2 mL of the product obtained in step 2) and 0.6 g of dopamine hydrochloride to a solution of 100 mL of deionized water dissolved in 0.2 g of trishydroxymethylaminomethane, stir for 4 hours, and wash with deionized water and absolute ethanol three times respectively , dried in an oven at 80°C to obtain a flower-like Mo-polydopamine composite (Mo-PDA);

[0043] 4) The product obtained in step 3) is placed in a tube furnace and sintered at 800°C for 4 hours in an Ar atmosphere to obtain uniformly bridged ultrafine MoO inside the sheet-like carbon matrix 2 Nanoparticle electrode materials.

[0044] The sheet-like carbon matrix obtained in this experimental examp...

Embodiment 3

[0046] 1) Mix 0.5g Mo powder and add 20mL H 2 o 2 and 20mL H 2 O mixed solution, stirred for 6h;

[0047] 2) Transfer the solution obtained in step 1) into a 100mL reactor and heat at 170°C for 12h, take out the reactor, and cool to room temperature naturally to obtain MoO 3 Nanobelt solution;

[0048] 3) Add 2 mL of the product obtained in step 2) and 0.2 g of dopamine hydrochloride to a solution of 0.1214 g of tris-hydroxymethylaminomethane dissolved in 100 mL of deionized water, stir for 4 hours, and wash with deionized water and absolute ethanol four times respectively , and dry;

[0049] 4) The product obtained in step 3) is placed in a tube furnace and sintered at 700° C. for 4 hours in an Ar atmosphere to obtain an electrode material uniformly bridged with ultrafine MoO2 nanoparticles inside the sheet-like carbon matrix.

[0050] The sheet-like carbon matrix obtained in this experimental example is uniformly bridged with ultra-fine MoO 2 Taking the electrode mater...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com