Up-conversion nanowire and preparation method and application thereof

A nanowire and aqueous solution technology, applied in the field of upconversion nanowire and its preparation, can solve the problems of small aspect ratio, tedious and time-consuming one-dimensional structure, and achieve bright upconversion luminescence, good ductility and stretchability, high The effect of flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A method for preparing upconversion nanowires, comprising the following steps:

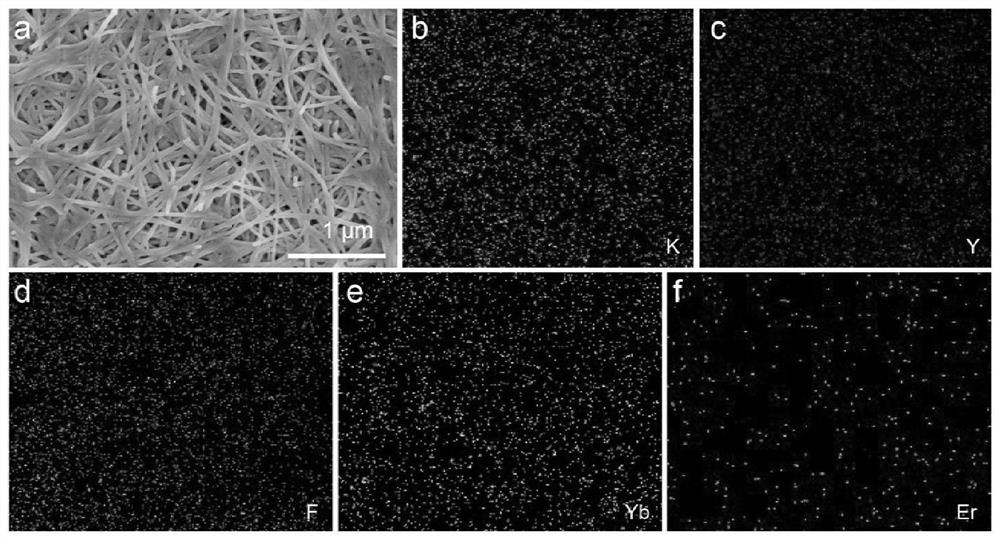

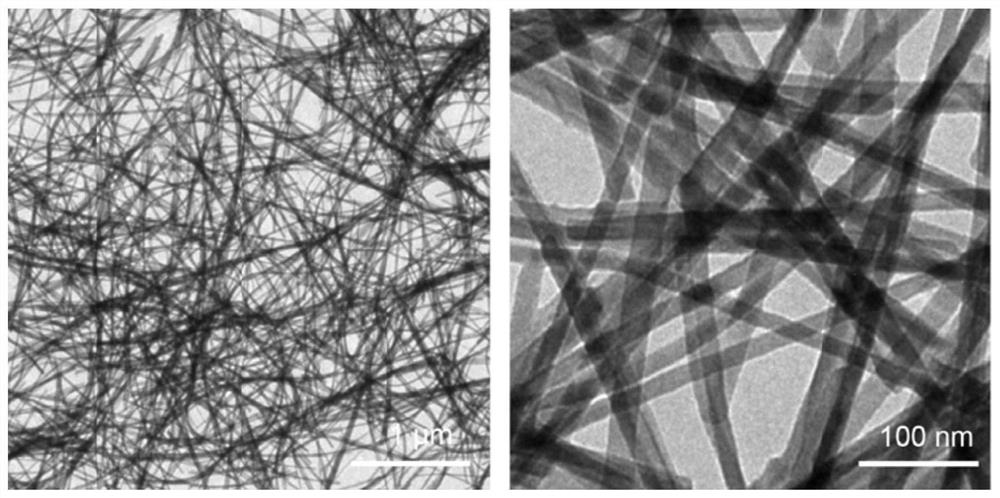

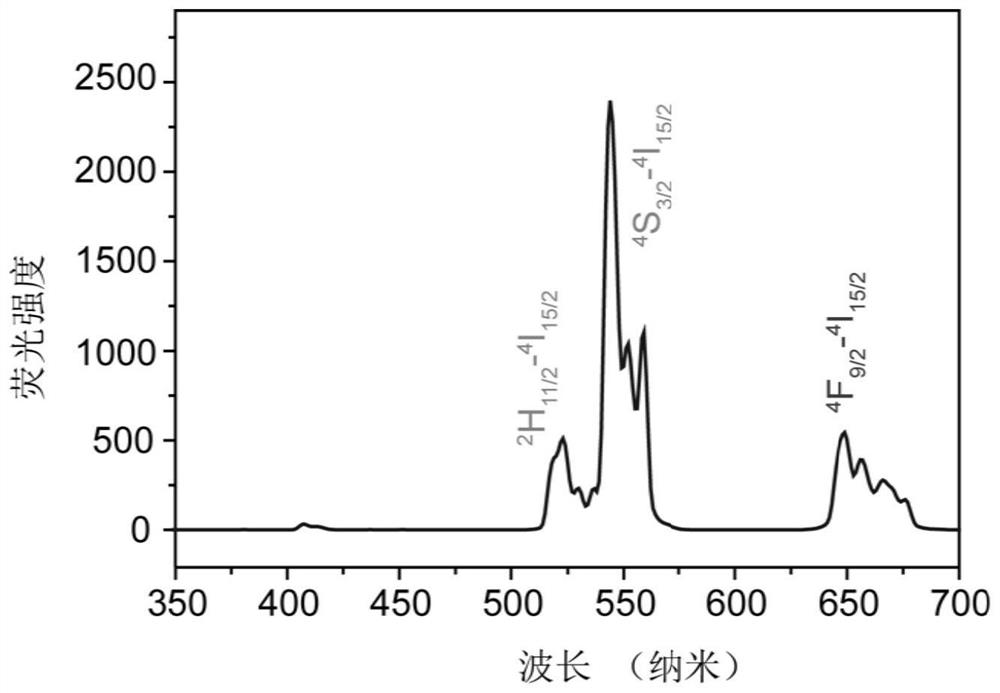

[0032] Synthesis of K by co-precipitation 2 YF 5:18%Yb / 2%Er, that is, the molar ratio of Y:Yb:Er=0.8:0.18:0.02, 1.6mL yttrium acetate aqueous solution (0.2M, namely 0.2mol / L), 0.36mL ytterbium acetate aqueous solution (0.2M , ie 0.2mol / L) and 0.04mL erbium acetate aqueous solution (0.2M, ie 0.2mol / L) were added into a 50mL double-necked flask containing 1.5mL oleic acid, and the above mixed solution was stirred and heated in an oil bath, and the temperature was raised to 160 ℃. After all the water was removed, 12 mL of 1-octadecene was added and maintained for 1.25 hours, then the heating was stopped and cooled to room temperature 25°C with stirring. Mix 3.5mL KF methanol solution (0.5M, ie 0.5mol / L) with 3mL KOH methanol solution (0.5M, ie 0.5mol / L) and quickly add to the two-necked flask, heat to 50°C under stirring and keep half Hours, continue to heat up to 100 ° C, cross vacuum and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com