Dutasteride soft capsule medicine composition

A technology of dutasteride and composition, applied in the field of pharmaceutical preparations, can solve problems such as drug migration problems of dutasteride soft capsules that have not been found, and achieve the effects of improving drug migration, low industrialization cost, and small capsule size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0093]

[0094]After adding prescription amounts of caprylic capric macrogol glyceride, dibutyl hydroxytoluene and dutasteride in a water bath at 60°C, stir to obtain the content.

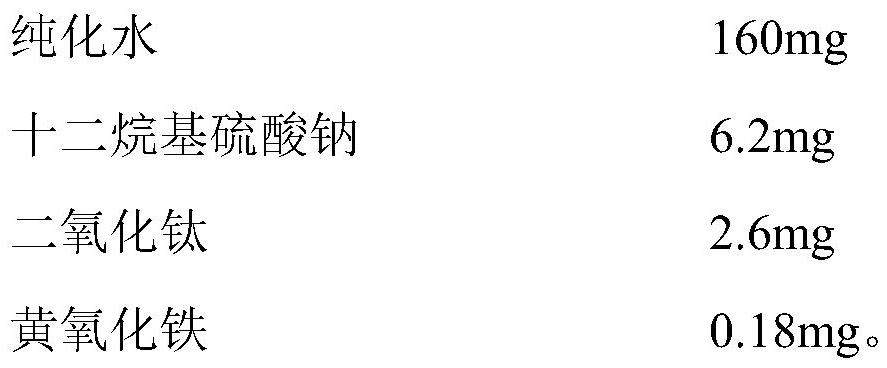

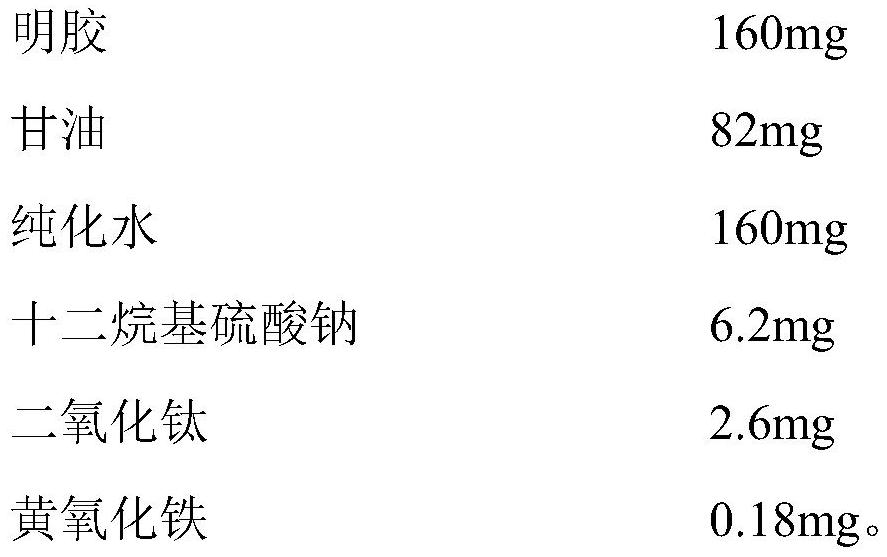

[0095] Add the prescribed amount of sodium lauryl sulfate, glycerin and purified water into the glue tank, heat the interlayer temperature to 75°C; add the prescribed amount of titanium dioxide, yellow iron oxide, and appropriate amount of purified water into the clean container, and The colloid mill circulates and grinds for 10 minutes, disperses evenly and puts it into the glue tank, rinses it with an appropriate amount of purified water, and then adds it to the glue tank together. Keep the temperature of the glue solution at 70°C, add the prescribed amount of gelatin, start stirring, control the vacuum degree of the glue tank to -0.08±0.005MPa, make the gelatin completely melt into liquid in the glue tank, and stop stirring when there are no gelatin particles , After there are no bubbles in t...

Embodiment 2

[0099]

[0100] After adding prescription amounts of caprylic capric macrogol glyceride, dibutyl hydroxytoluene and dutasteride in a water bath at 60°C, stir to obtain the content.

[0101] Add the prescribed amount of sodium lauryl sulfate, glycerin and purified water into the glue tank, heat the interlayer temperature to 75°C; add the prescribed amount of titanium dioxide, yellow iron oxide, and appropriate amount of purified water into the clean container, and The colloid mill circulates and grinds for 10 minutes, disperses evenly and puts it into the glue tank, rinses it with an appropriate amount of purified water, and then adds it to the glue tank together. Keep the temperature of the glue solution at 70°C, add the prescribed amount of gelatin, start stirring, control the vacuum degree of the glue tank to -0.08±0.005MPa, make the gelatin completely melt into liquid in the glue tank, and stop stirring when there are no gelatin particles , After there are no bubbles in ...

Embodiment 3

[0105]

[0106] After adding prescription amounts of caprylic capric macrogol glyceride, dibutyl hydroxytoluene and dutasteride in a water bath at 60°C, stir to obtain the content.

[0107] Add the prescribed amount of sodium lauryl sulfate, glycerin and purified water into the glue tank, heat the interlayer temperature to 75°C; add the prescribed amount of titanium dioxide, yellow iron oxide, and appropriate amount of purified water into the clean container, and The colloid mill circulates and grinds for 10 minutes, disperses evenly and puts it into the glue tank, rinses it with an appropriate amount of purified water, and then adds it to the glue tank together. Keep the temperature of the glue solution at 70°C, add the prescribed amount of gelatin, start stirring, control the vacuum degree of the glue tank to -0.08±0.005MPa, make the gelatin completely melt into liquid in the glue tank, and stop stirring when there are no gelatin particles , After there are no bubbles in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com