Layered manganese-based positive electrode material of sodium-ion battery and preparation method thereof

A technology of sodium ion battery and cathode material, which is applied in the field of electrochemistry to achieve the effects of good safety performance, short preparation time and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

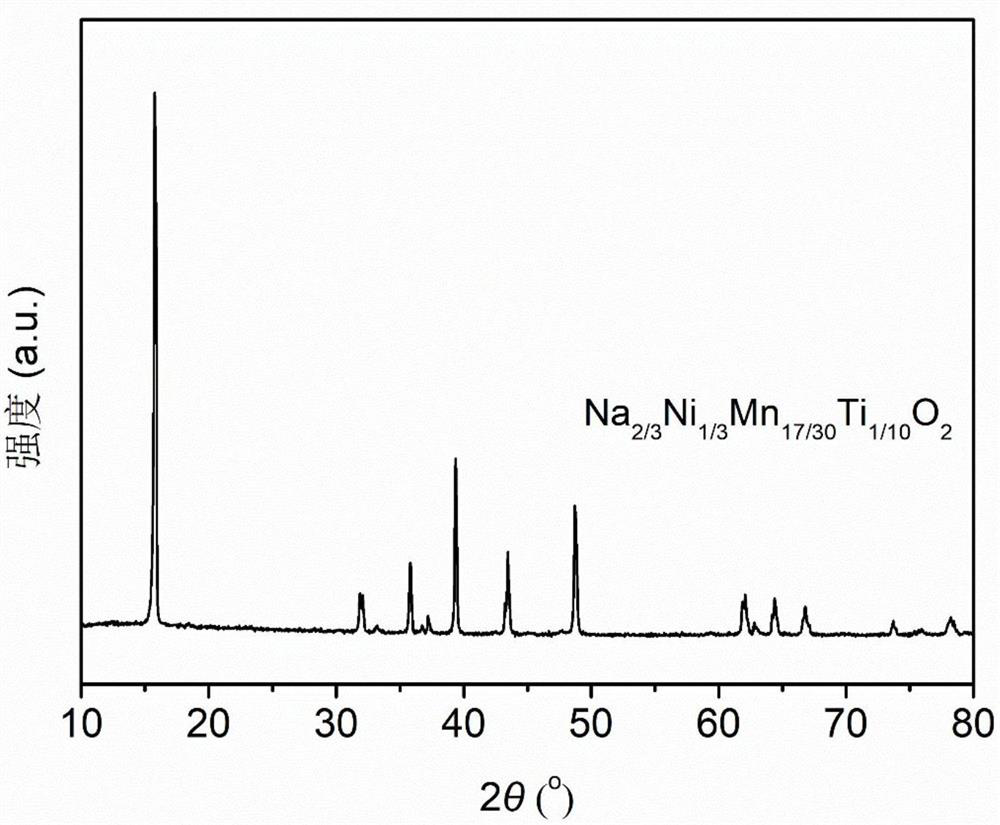

[0041] Na 2 / 3 Ni 1 / 3 mn 2 / 3-x Ti x o 2 The preparation method of (x=1 / 10) comprises the following steps: take by weighing 1.20g sodium nitrate, 4.08g manganese nitrate, 1.92g nickel nitrate hexahydrate and 0.58g tetrabutyl titanate are dissolved in distilled water, then add 6.42g anhydrous Citric acid, heated to 60°C and subjected to magnetic stirring to obtain a gel. The gel was dried at 100°C for 5 h to obtain a solid sample, which was then manually ground into a powder. The obtained sample was transferred to a tube furnace, heated to 700°C in an air atmosphere for calcination, the heating rate was 5°C / min, calcined for 12 hours, and the positive electrode material was obtained after natural cooling, and its molecular formula was Na 2 / 3 Ni 1 / 3 mn 17 / 30 Ti 1 / 10 o 2 .

Embodiment 2

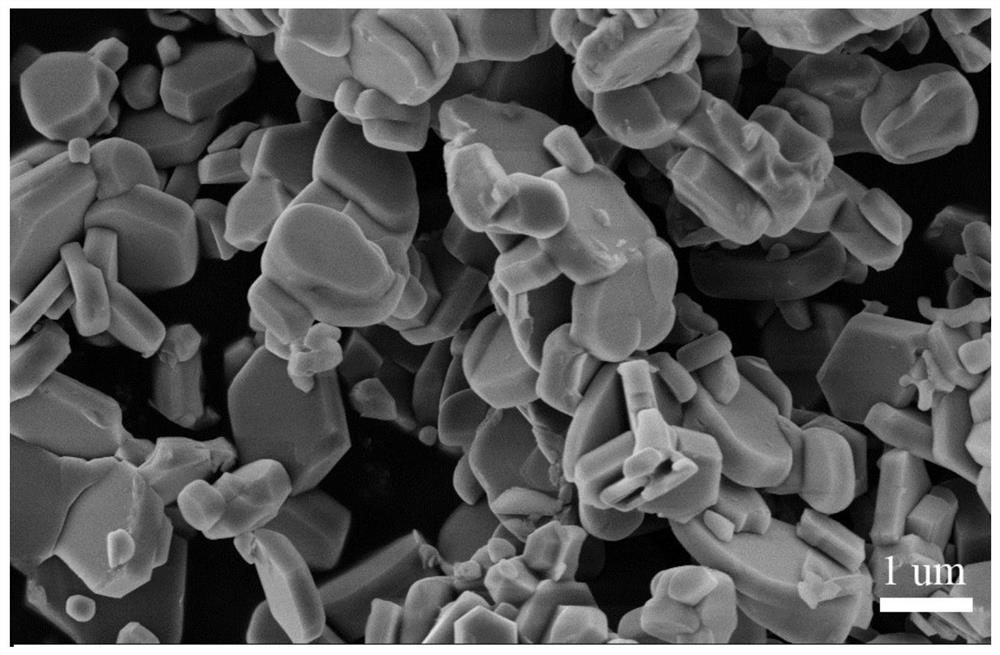

[0043] Na 2 / 3 Ni 1 / 3 mn 2 / 3-x Ti x o 2 The preparation method of (x=1 / 10) comprises the following steps: take by weighing 1.20g sodium nitrate, 4.08g manganese nitrate, 1.92g nickel nitrate hexahydrate and 0.58g tetrabutyl titanate are dissolved in distilled water, then add 6.42g anhydrous Citric acid, heated to 70°C and subjected to magnetic stirring to obtain a gel. The gel was dried at 100°C for 6 h to obtain a solid sample, which was then manually ground into powder. The obtained sample was transferred to a tube furnace, heated to 900°C in an air atmosphere for calcination, the heating rate was 5°C / min, and calcined for 10 hours. After natural cooling, the positive electrode material was obtained, and its molecular formula was Na 2 / 3 Ni 1 / 3 mn 17 / 30 Ti 1 / 10 o 2 . Na prepared in this example 2 / 3 Ni 1 / 3 mn 17 / 30 Ti 1 / 10 o 2 See the XRD pattern of figure 1 , SEM image see image 3 . Na prepared in this example 2 / 3 Ni 1 / 3 mn 17 / 30 Ti 1 / 10 o 2 The first...

Embodiment 3

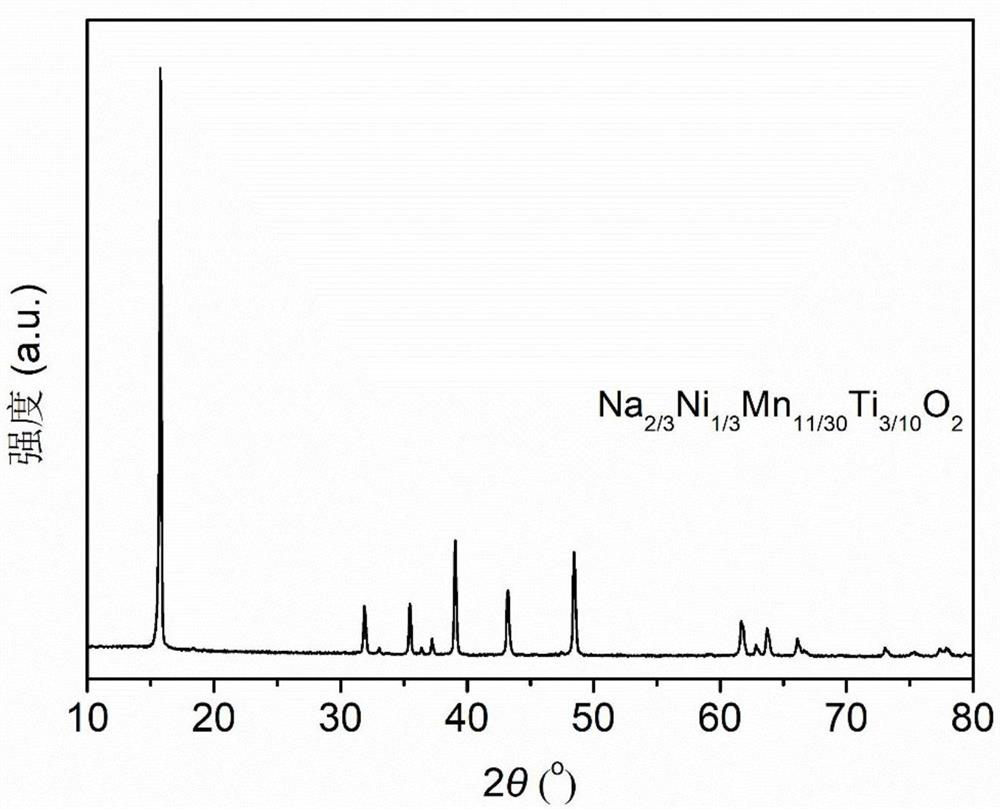

[0045] Na 2 / 3 Ni 1 / 3 mn 2 / 3-x Ti x o 2 The preparation method of (x=2 / 10) comprises the following steps: take by weighing 1.20g sodium nitrate, 3.365g manganese nitrate, 1.92g nickel nitrate hexahydrate and 1.36g tetrabutyl titanate are dissolved in distilled water, then add 6.42g anhydrous Citric acid, heated to 60°C and subjected to magnetic stirring to obtain a gel. The gel was dried at 100°C for 5 h to obtain a solid sample, which was then manually ground into a powder. The obtained sample was transferred to a tube furnace, heated to 700°C in an air atmosphere for calcination, the heating rate was 5°C / min, calcined for 12 hours, and the positive electrode material was obtained after natural cooling, and its molecular formula was Na 2 / 3 Ni 1 / 3 mn 7 / 15 Ti 2 / 10 o 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com