SiOx-C composite fiber felt anode material as well as preparation method and application thereof

A technology of composite fiber felt and composite fiber, which is applied in the field of SiOx-C composite fiber felt negative electrode material and its preparation, can solve the problem of SEI on the surface of electrode material to be further deepened, lower charge and discharge efficiency of electrode material, increase of irreversible capacity for the first charge and discharge, etc. problem, achieve the effect of reducing the first capacity loss, improving cycle stability, and avoiding aggregation and shedding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

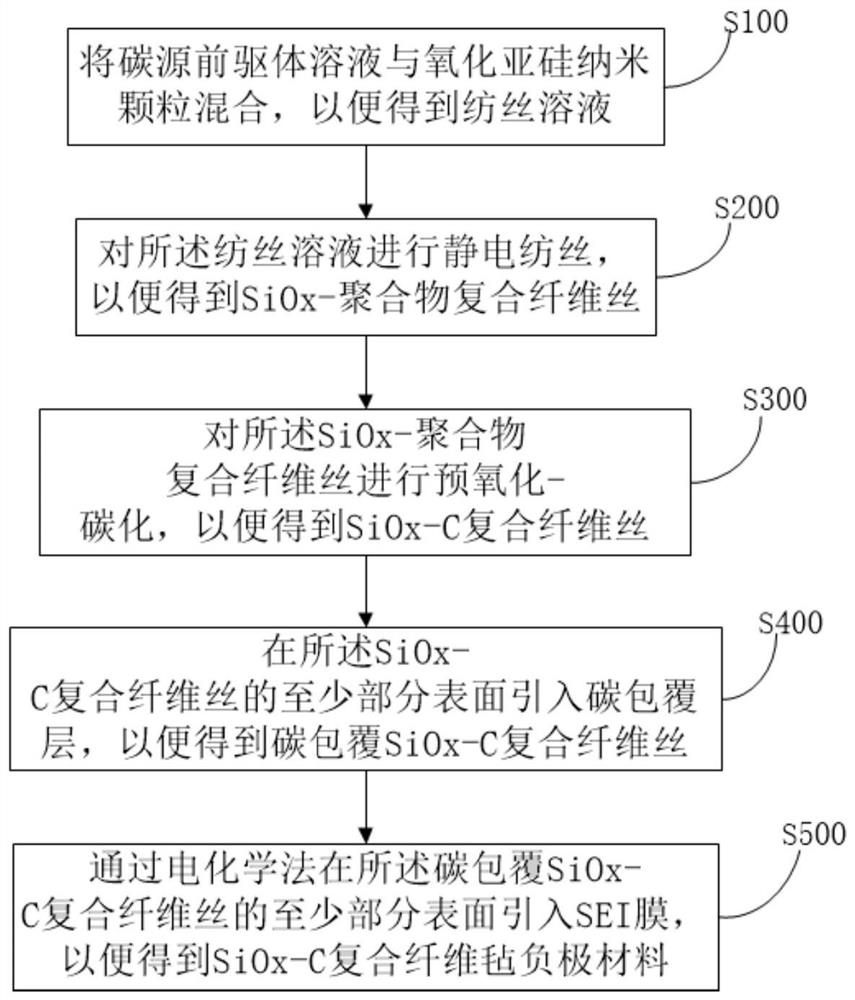

[0066] According to the method for preparing the above-mentioned SiOx-C composite fiber felt negative electrode material according to the embodiment of the present invention, the method uses electrospinning to fix the silicon oxide particles inside or on the surface of the carbon-based conductive matrix, and the silicon oxide particles can be fixed In the negative electrode conductive system, it is conducive to the stability of battery cycle performance. The silica nanoparticles are uniformly dispersed inside or on the surface of the carbon fiber matrix, which avoids the agglomeration of such nanomaterials during repeated charging and discharging. The carbon fibers link all the silica particles together to form a conductive network. Compared with coating the active material on the current collector Cu foil used in the traditional negative electrode, this method avoids the problem of silicon oxide particles being pulverized and detached from the conductive network. In order to ...

Embodiment 1

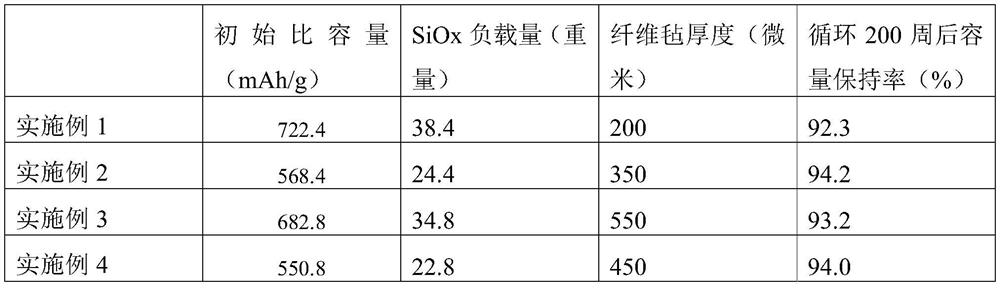

[0072] Under magnetic stirring, slowly add 30g of polyacrylonitrile (PAN) powder into 270mL of N,N-dimethylformamide (DMF), fully dissolve until the solution becomes clear and transparent, then add 10g of SiOx particles, as a spinning silk solution. An electrospinning machine is used to spin SiOx-polymer composite fiber filaments, and these composite fiber filaments are overlapped to form a SiOx-polymer composite fiber mat. Pre-oxidize the above SiOx-polymer composite fiber mat, keep it at 250 degrees Celsius for 3 hours, and the heating rate is 3 degrees Celsius / min; carbonize the pre-oxidized product, keep it at 800 degrees Celsius for 5 hours, and obtain SiOx-C fiber mat.

[0073] The SiOx content in the obtained SiOx-C fiber mat is 38.4%, and the thickness of the SiOx-C fiber mat is 200 μm.

[0074] Using natural gas as the carbon source, the carbon coating layer was coated on the surface of SiOx-C composite fiber by CVD method.

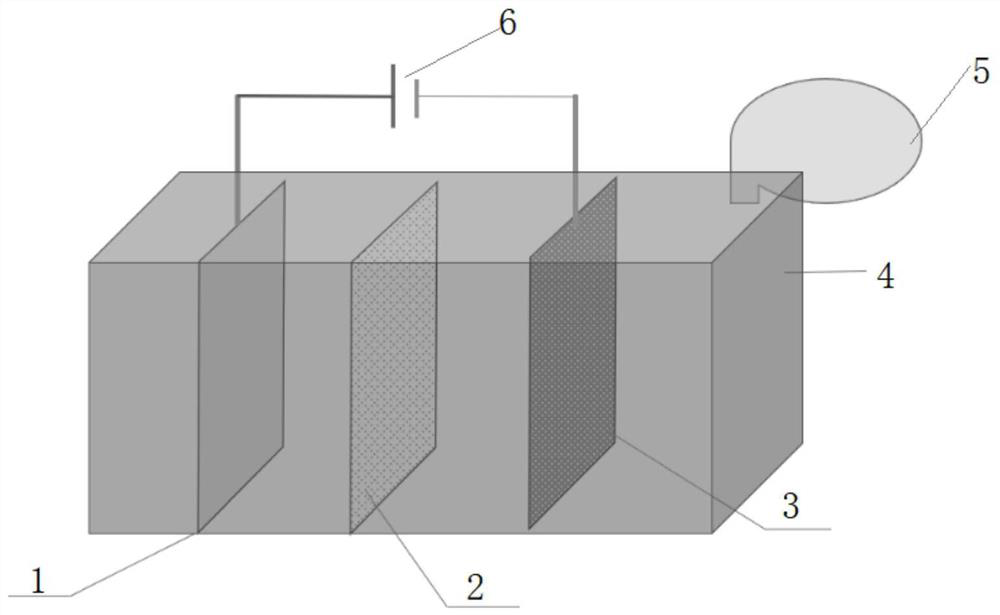

[0075] In the synthetic electrolytic cel...

Embodiment 2

[0078] Under magnetic stirring, 30 g of polyvinyl acetate (PVAc) particles were slowly added to 270 mL of acetone, fully dissolved until the solution became clear and transparent, and then 5 g of SiOx particles were added as a spinning solution. An electrospinning machine is used to spin SiOx-PVAc composite fiber filaments, and these composite fiber filaments are overlapped to form a SiOx-PVAc composite fiber mat. Pre-oxidize the above SiOx-PVAc composite fiber mat, keep it at 270 degrees Celsius for 4 hours, and the heating rate is 5 degrees Celsius / minute; carbonize the pre-oxidized product, and keep it at 900 degrees Celsius for 4 hours to obtain a SiOx-C fiber mat.

[0079] The SiOx content in the obtained SiOx-C fiber mat is 24.4%, and the thickness of the SiOx-C fiber mat is 350 μm.

[0080] Using natural gas as the carbon source, the carbon coating layer was coated on the surface of SiOx-C composite fiber by CVD method.

[0081] In the synthetic electrolytic cell of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com