Hydrogel lacrimal passage suppository and preparation method thereof

A hydrogel lacrimal duct and hydrogel technology, which is applied in suppository delivery, pharmaceutical formulations, preparations for in vivo tests, etc., can solve the problems of short maintenance time, increase in diameter, frequent replacement, etc., and achieve mild process conditions, The effect of reducing air bubbles and reducing breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0060] The invention provides a method for preparing a hydrogel lacrimal plug, comprising:

[0061] 1. Preparation of hydrogel prepolymer

[0062] The polymer was dissolved in the buffer salt system, and placed in a low-temperature centrifuge for defoaming treatment to obtain the first uniform solution (solution I),

[0063] Then add the cross-linking agent and the color developing agent into the buffer salt system to obtain the second mixed solution (solution II).

[0064] 2. Preparation and molding of wet gel

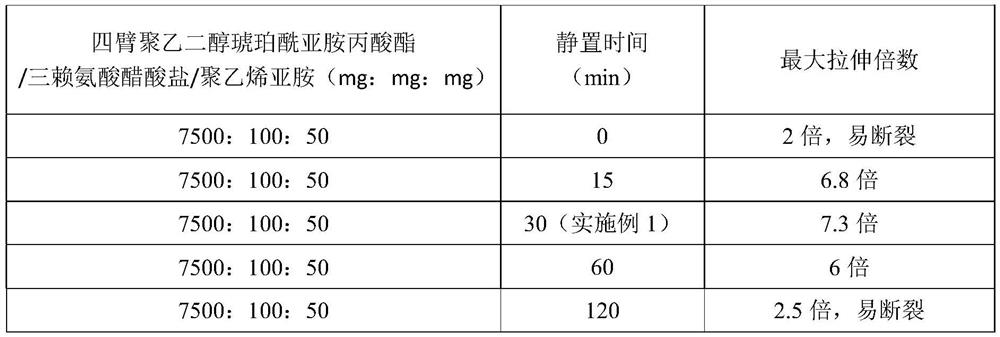

[0065] Mix the first homogeneous solution and the second mixed solution evenly, pressurize and inject into the mold (tubular mold) and let stand to form a hydrogel.

[0066] 3. Preparation of dry gel

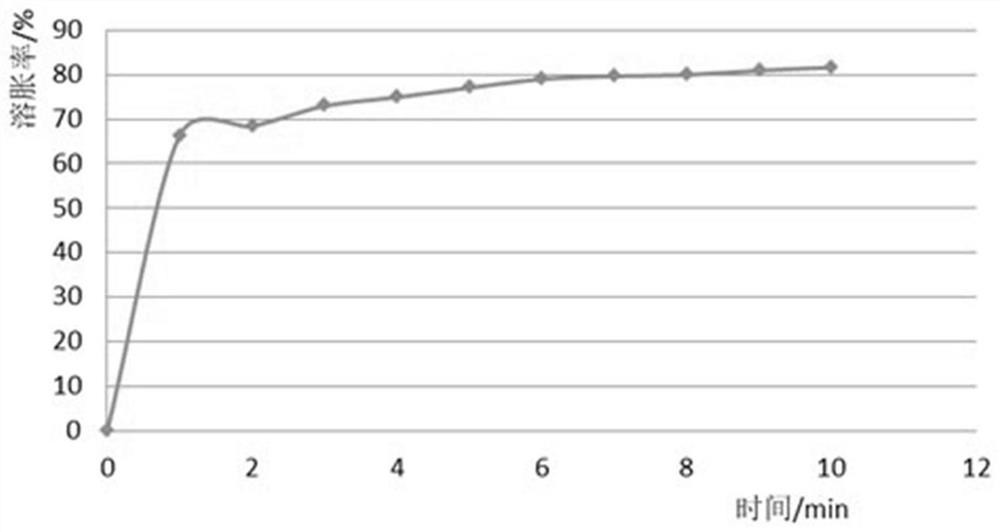

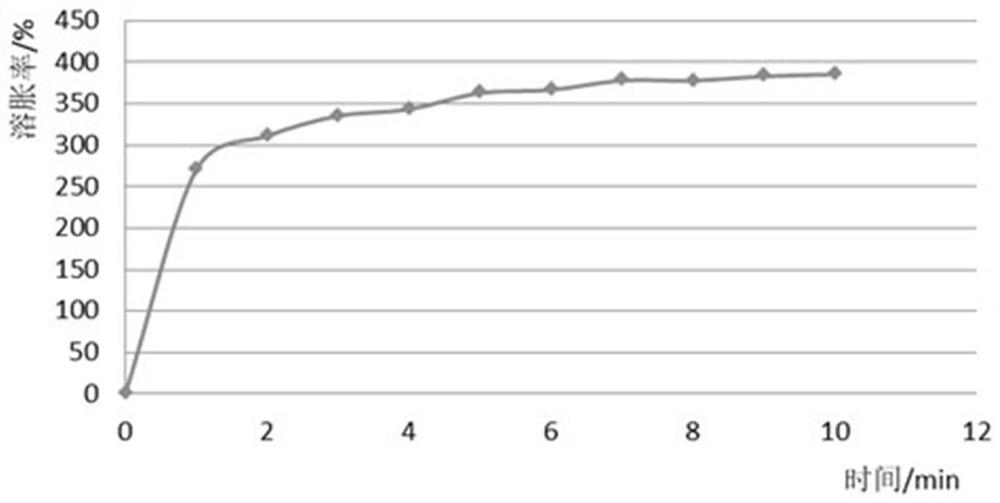

[0067] The hydrogel is taken out after drying at room temperature for a suitable time (preliminary dehydration to obtain a wet hydrogel), and then placed at room temperature for a period of time (further dehydration), and then uniformly stretched to a fixed length at...

Embodiment 1

[0071] The preparation of embodiment 1 hydrogel lacrimal plug

[0072] 1. Add 7500mg of four-armed polyethylene glycol succinimide propionate (molecular weight: 20000±1000Da) into 20mL of 0.015M borate buffer, stir to dissolve, and place in a centrifuge for low-temperature centrifugation for defoaming treatment. Setting conditions: rotation speed 2000r / min, temperature 5°C, time 2min, to obtain the first uniform solution (Solution I).

[0073] Dissolve 100mg trilysine acetate, 50mg polyethyleneimine (molecular weight 10000Da) and 10mg N-hydroxysuccinimide fluorescein in 10mL 0.015M borate buffer to obtain the second mixed solution (Solution II) .

[0074] 2. Mix the first uniform solution and the second mixed solution evenly.

[0075] 3. Pour the mixed solution into a silicone tube with an inner diameter of 1.7 mm, let it stand for 1 min, and form a hydrogel after chemical crosslinking.

[0076] 4. Dry the hydrogel at room temperature and normal pressure for 2 hours, take o...

Embodiment 2

[0079] Embodiment 2 Preparation of hydrogel lacrimal plug

[0080] 1. Add 2500mg of eight-armed polyethylene glycol maleimide (molecular weight 20000±1000Da) to 20mL of 0.015M borate buffer solution, stir to dissolve, and place it in a centrifuge for defoaming treatment. The setting conditions of the centrifuge are: speed 2000r / min, temperature 5°C, time 2min, the first homogeneous solution (Solution I) was obtained.

[0081] 100mg trilysine acetate, 50mg polyethyleneimine (molecular weight 10000Da) and 10mg N-hydroxysuccinimide fluorescein were dissolved in 10mL of 0.015M borate buffer to obtain the second mixed solution (Solution II ).

[0082] 2. Add the second mixed solution to the first solution, stir and mix evenly.

[0083] 3. Pour the mixed solution into a silicone tube with an inner diameter of 1.7 mm, let it stand for 1 min, and form a hydrogel after chemical crosslinking.

[0084] 4. Dry the hydrogel at room temperature and normal pressure for 2 hours, take out t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com