Flue gas dry desulfurization process

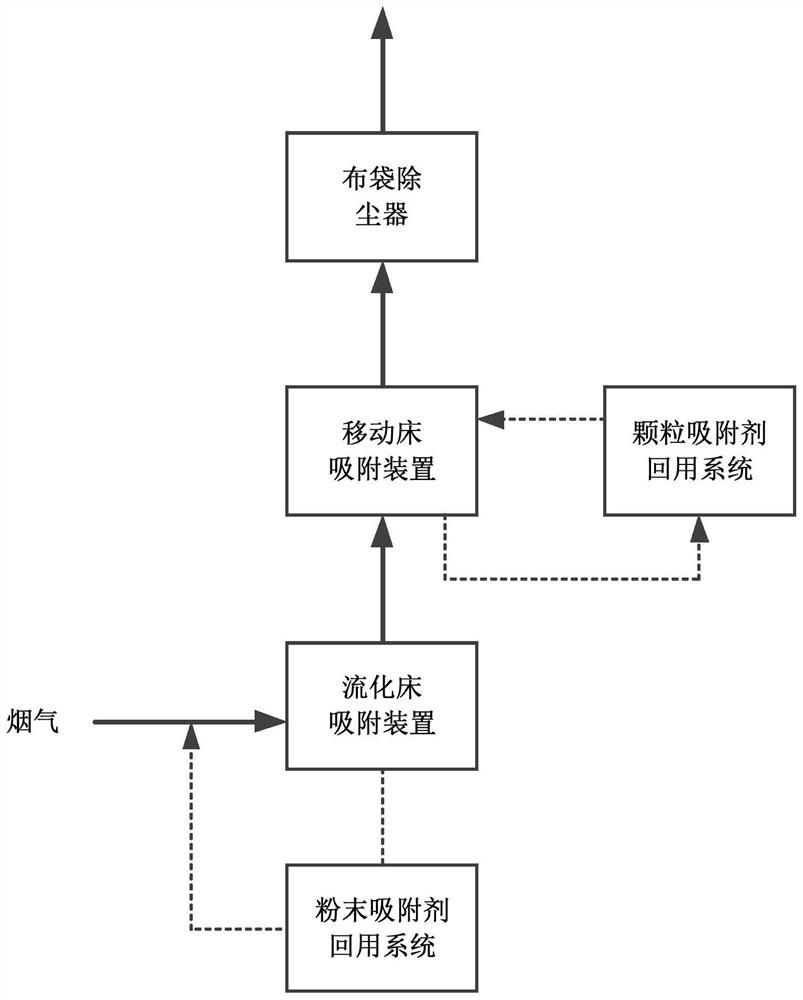

A dry desulfurization and flue gas technology, which is applied to the adsorption and removal of flue gas gaseous pollutants and the flue gas dry desulfurization process field, can solve the problems of low efficiency, complicated solid treatment of calcium sulfate and sodium sulfate, and reaction rate between gas and solid phases. Slow and other problems, to achieve the effect of improving removal efficiency, fast adsorption speed, and improving utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The present invention utilizes a separate fluidized bed adsorption device and a moving bed adsorption device in the laboratory to carry out combined flue gas dry desulfurization experimental research, and the simulated non-ferrous metal smelting flue gas is provided by calcining lead sulfide ore powder in a rotary kiln. 100Nm 3 / h. After the flue gas at the outlet of the rotary kiln passes through the cooling device, it is passed through the above-mentioned flue gas dry desulfurization process, and finally the flue gas enters the bag filter, and the flue gas is dedusted by the bag filter, and the dust and powder adsorbent Filter and capture, and use the adsorbent layer accumulated on the surface of the filter bag to reduce the SO in the flue gas 2 Perform deep removal. The flue gas temperature at the outlet of the cooling device downstream of the rotary kiln is maintained at 200 °C, SO 2 The concentration is 1000mg / Nm 3 , the dust concentration is 1g / Nm 3 , the gas ...

Embodiment 2

[0037] Using the same fluidized bed and moving bed coupling device as in Example 1 to carry out the flue gas dry desulfurization process, the SO in the flue gas 2 The concentration is 1000mg / Nm 3 , spray a certain amount of powdered adsorbent (magnesium carbonate) into the pipeline, and the concentration of powdered adsorbent in the flue gas is 100mg / m 3 . The granular adsorbent is activated alumina pellets (5mm in diameter), and the moving speed of the granular adsorbent in the moving bed is 10mm / s. The velocity of the flue gas in the fluidization section is 5m / s, and after the filtration velocity of the moving bed is 1m / min through the flue gas dry desulfurization process of the present invention, the concentration of flue gas dust is 0.01g / Nm 3 , SO 2 The concentration is 50mg / Nm 3 , SO 2 The removal efficiency is about 95%.

Embodiment 3

[0039] Using the same flue gas dry desulfurization process as in Example 1 to carry out the experiment, the SO in the flue gas 2 The concentration is 1000 mg / Nm 3 , spray a certain amount of powder adsorbent (magnesium carbonate) into the pipeline, and the concentration of powder adsorbent in the flue gas is 200mg / m 3 . The granular adsorbent selects activated alumina pellets (3 mm in diameter), and the moving speed of the granular adsorbent in the moving bed is 10 mm / s. The velocity of the flue gas in the fluidization section is 5m / s, and the filtration velocity of the moving bed is 1m / min. After passing through the flue gas dry desulfurization process of the present invention, the flue gas dust concentration is 0.01g / Nm 3 , SO 2 The concentration is 30mg / Nm 3 , SO 2 The removal efficiency is about 97%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com