Preparation method and application of novel chloride ion removal material Ti3C2Tx/Ag

A new type of chloride ion technology, applied in separation methods, nanotechnology for materials and surface science, chemical instruments and methods, etc., can solve the problems of less research on dechlorination electrodes, slow desalination rate, and low desalination capacity, etc Suitable for large-scale production, potential stability, high desalination capacity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

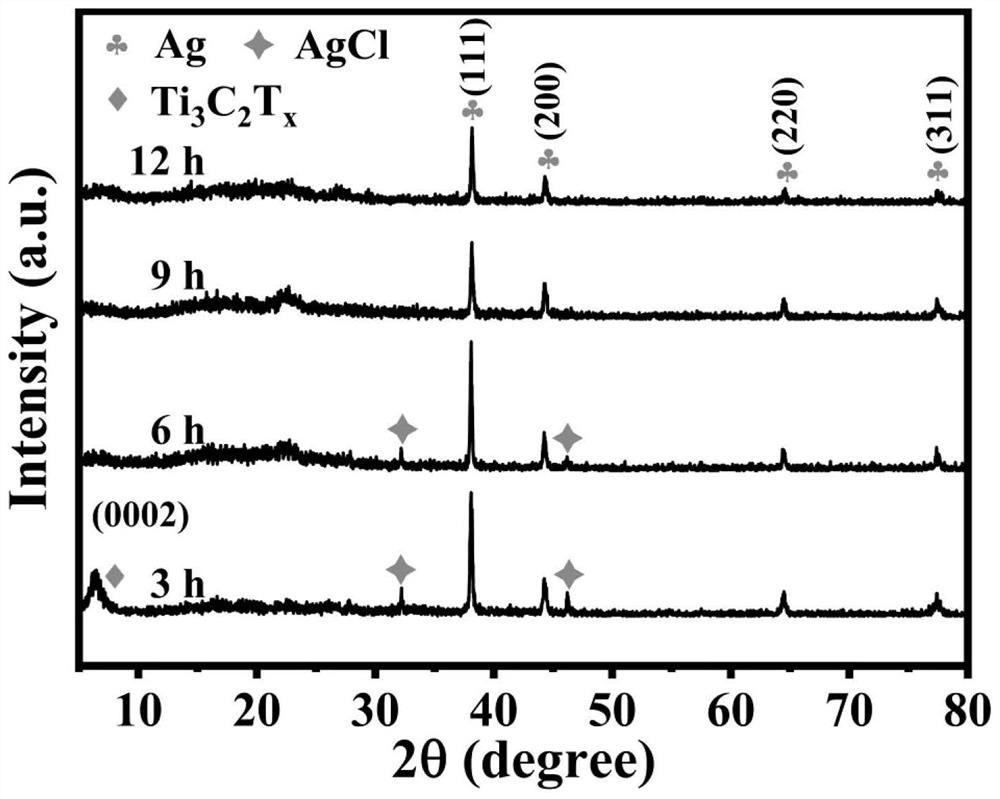

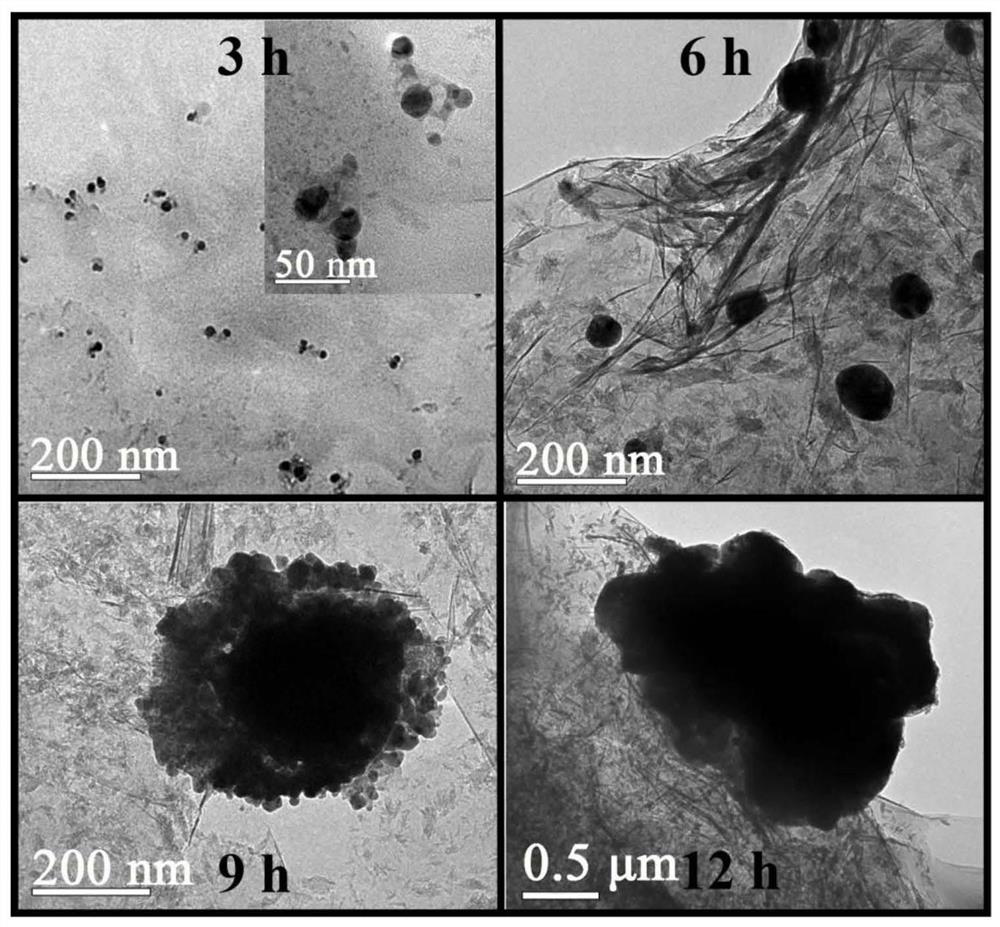

[0048] The new chloride ion removal material Ti based on the battery-pseudocapacitive coupling mechanism of this embodiment 3 C 2 T x The preparation method of / Ag comprises the steps:

[0049] (1) Weigh 1g of LiF and add it to the hydrochloric acid solution (5mL of deionized water mixed with 15mL of 36%-38% concentrated hydrochloric acid) to obtain the first mixed solution, and heat it in a water bath at 40°C for 30min;

[0050] (2) Add Ti in the first mixed solution 3 AlC 2 , to obtain the second mixed solution, continue heating in a water bath at 40°C for 24h;

[0051] (3) Wash the second mixed solution obtained with absolute ethanol and deionized several times until the pH of the solution is greater than 5, and vacuum dry at 60° C. to obtain a sheet Ti 3 C 2 T x powder;

[0052] (4) Take 1g of the lamella Ti obtained above 3 C 2 T x Powder, dispersed in 250mL deionized water, ultrasonically stripped under Ar atmosphere for 1h, centrifuged at 3500rpm for 60min, t...

Embodiment 2

[0061] The new chloride ion removal material Ti based on the battery-pseudocapacitive coupling mechanism of this embodiment 3 C 2 T x The preparation method of / Ag comprises the steps:

[0062] (1) Preparation of 2mg / mL, 15mL few-layer Ti 3 C 2 T x solution;

[0063] (2) Weigh 25.39mg of AgNO 3 Dissolve the solid in 5mL deionized water, and add 138μL, 1mol / L hydrochloric acid solution drop by drop under ultrasonication to form AgCl colloid;

[0064] (3) Add the AgCl colloid obtained above to the few-layer Ti 3 C 2 T x solution, and then put the obtained mixture into a constant temperature shaker, and shake it at 25°C and 150rpm for 6h;

[0065] (4) vacuum filter and separate the reacted mixed solution, wash with deionized water, and then dry naturally at room temperature to obtain Ti 3 C 2 T x / Ag-6 film.

Embodiment 3

[0067] The new chloride ion removal material Ti based on the battery-pseudocapacitive coupling mechanism of this embodiment 3 C 2 T x The preparation method of / Ag comprises the steps:

[0068] (1) Preparation of 2mg / mL, 15mL few-layer Ti 3 C 2 T x solution;

[0069] (2) Weigh 25.39mg of AgNO 3 Dissolve the solid in 5mL deionized water, and add 138μL, 1mol / L hydrochloric acid solution drop by drop under ultrasonication to form AgCl colloid;

[0070] (3) Add the AgCl colloid obtained above to the few-layer Ti 3 C 2 T x solution, and then put the obtained mixture into a constant temperature shaker, and shake it at 25°C and 150rpm for 9h;

[0071] (4) vacuum filter and separate the reacted mixed solution, wash with deionized water, and then dry naturally at room temperature to obtain Ti 3 C 2 T x / Ag-9 film.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com