Photoresist-free photoinduced patterning method of quantum dot film

A quantum dot and patterning technology, applied in the field of photoresist-free photopatterning, can solve the problems of unfavorable high-resolution, high-performance patterned quantum dot films, etc., and achieve a wide range of applications, easy application, and high photoluminescence. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

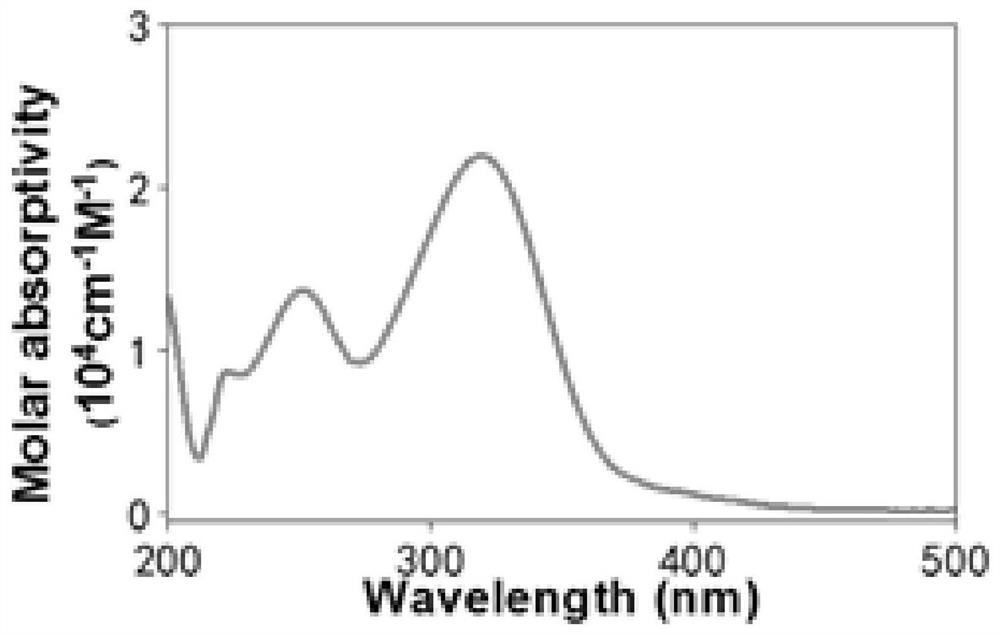

[0055] Synthesis of embodiment 1 photosensitive crosslinking molecule

[0056] Add 358 mg of sodium azide and 980 mg of pentafluorobenzaldehyde into a double-neck round bottom flask connected with a reflux condenser, pour 7.5 mL of acetone and 7.5 mL of water. The reaction solution was stirred and heated to reflux for 18 hours under the protection of nitrogen. After the reaction, the product was cooled to room temperature, and then 25 mL of water was added to dilute the initial reaction mixture, followed by extraction with 25 mL of ether, which was repeated three times. The organic layer was washed with saturated brine, dried over magnesium sulfate to remove water, and then distilled under reduced pressure to obtain a concentrated solution. Then it was purified by silica gel chromatography, and the eluent was a mixed solvent of ethyl acetate and n-hexane (volume fraction of ethyl acetate was 5%). After recrystallization from n-hexane, 680 mg of white solid 4-azido-2,3,5,6-te...

Embodiment 2

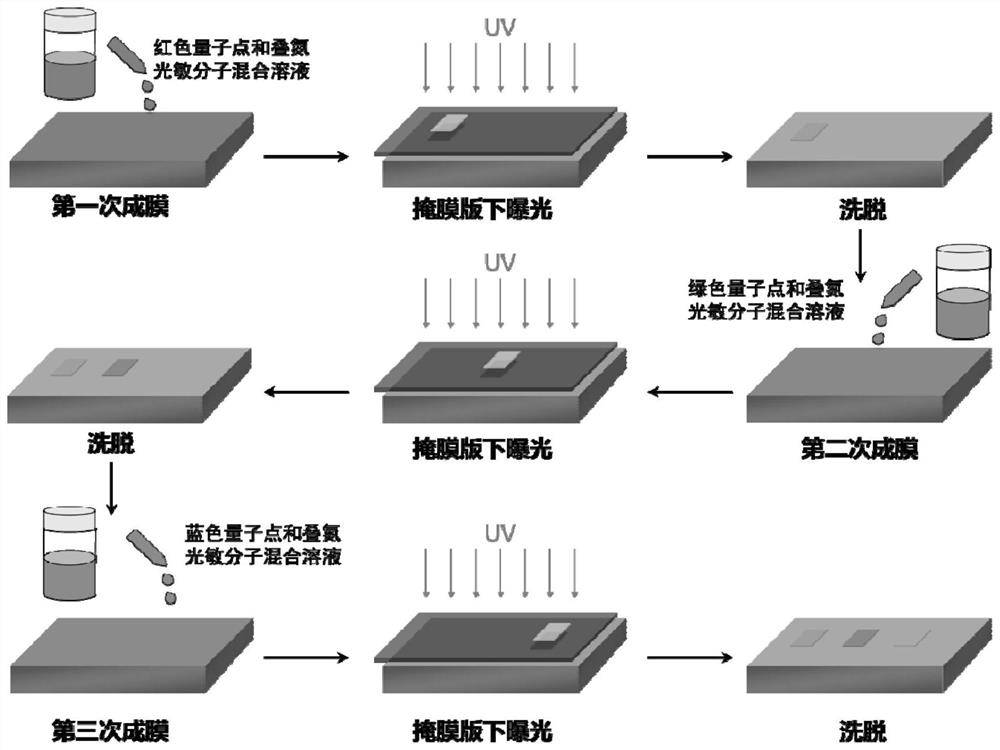

[0058] Embodiment 2 patterning process

[0059] Using the method disclosed in the existing literature to synthesize CdSe / ZnS core-shell quantum dots emitting red light, the patterning process is as follows:

[0060] In order to avoid the influence of external ultraviolet light on the patterning process, the following operations must be performed under yellow light:

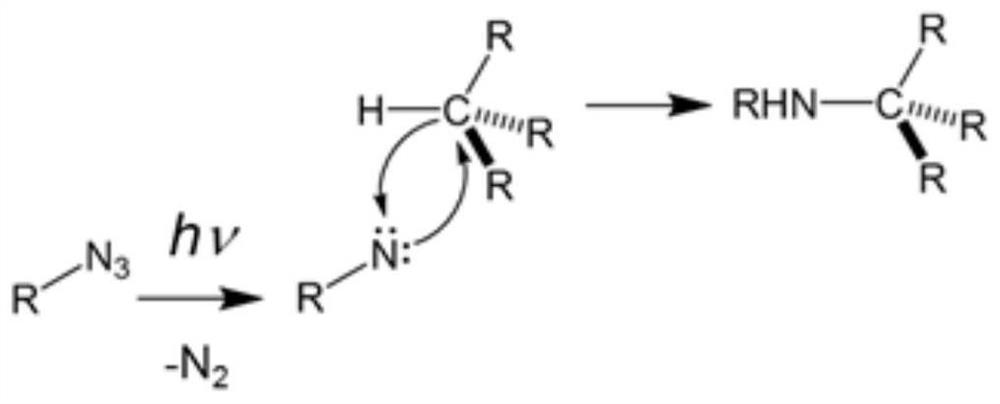

[0061] 1) Quantum dot film preparation: disperse the synthesized red CdSe / ZnS quantum dots in toluene, add the photosensitive crosslinking molecule (3E,5E)-3,5-bis(4-azido-2) synthesized in Example 1 ,3,5,6-Tetrafluorobenzylidene)-1-methylpiperidin-4-one, and stir and mix evenly, the quantum dot concentration is 30mg / mL, (3E,5E)-3,5- The molecular concentration of bis(4-azido-2,3,5,6-tetrafluorobenzylidene)-1-methylpiperidin-4-one is 2.5mg / mL, that is, quantum dots and photosensitive cross-linked molecules The mass ratio is 100:12.

[0062] Silicon is used as the substrate to prepare the quantum dot film. The sub...

Embodiment 3

[0067] Same as the patterning method of Example 2, the difference is that the quantum dots used are CdSe, and the optical microscope photo of the quantum dot film made in this embodiment is shown in Figure 5 a.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com