Preparation method and application of temperature-sensitive antler cartilage matrix hydrogel material

A cartilage matrix, hydrogel technology, applied in medical science, tissue regeneration, prosthesis, etc., can solve problems such as incomplete cell removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

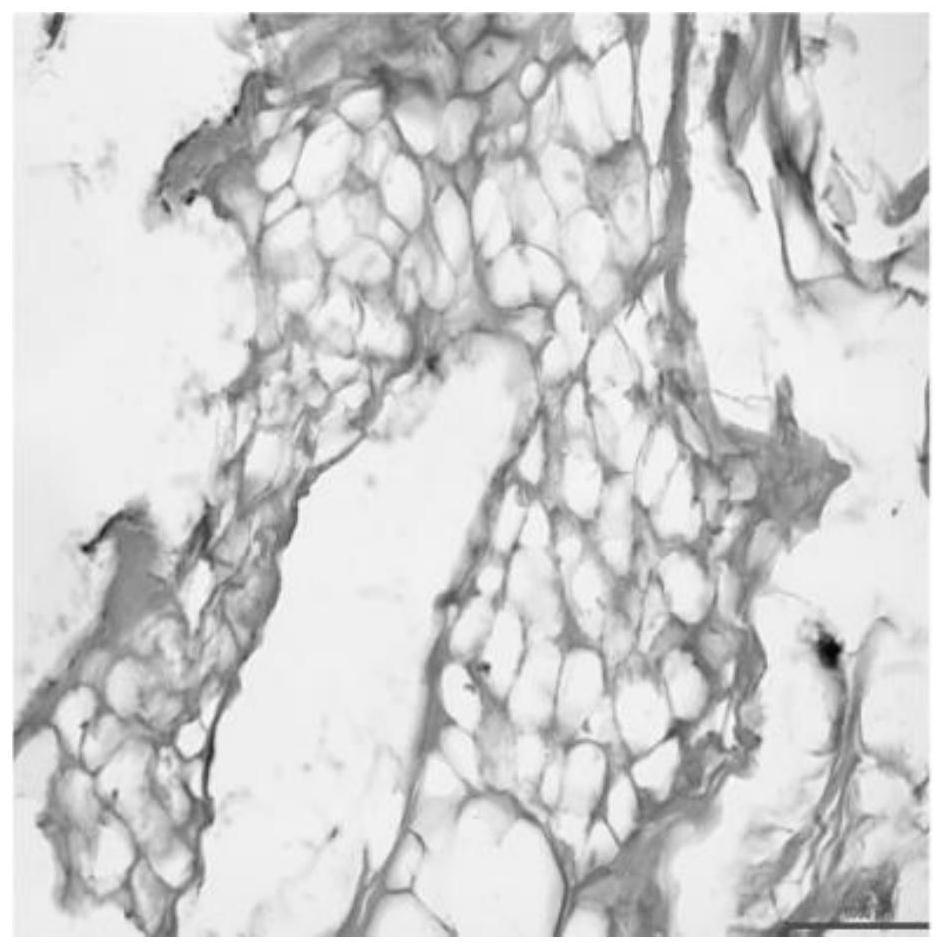

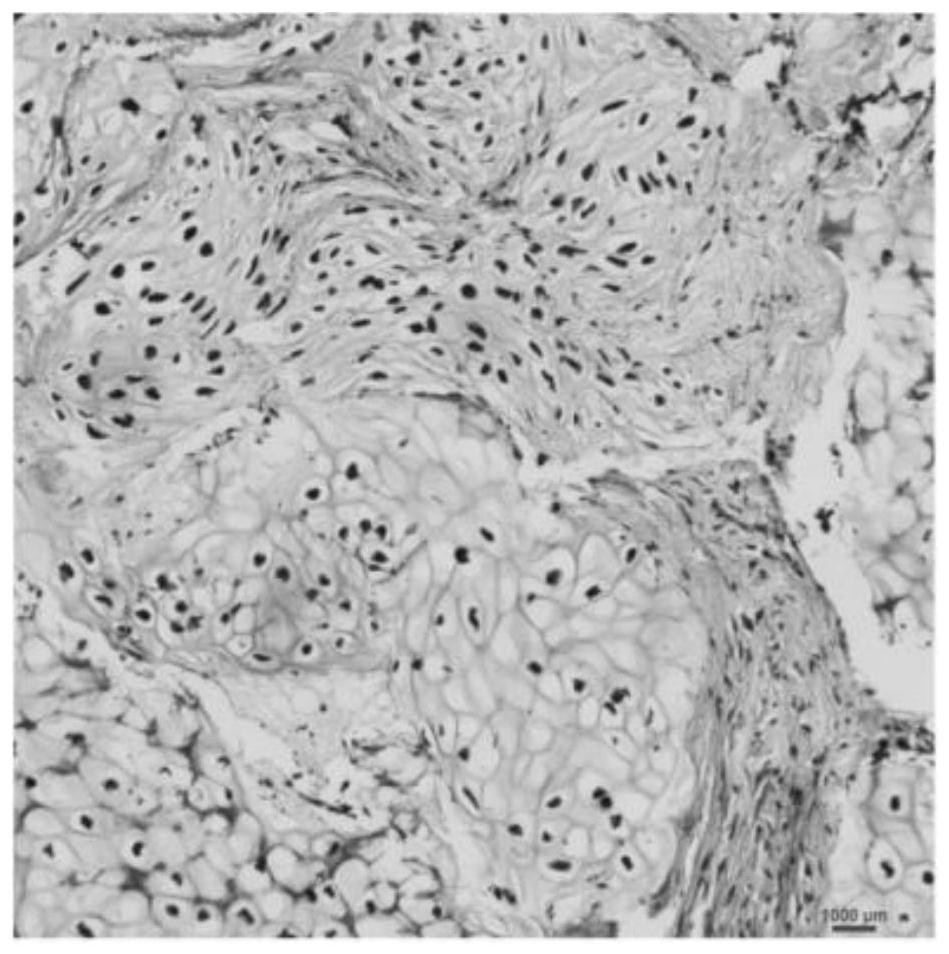

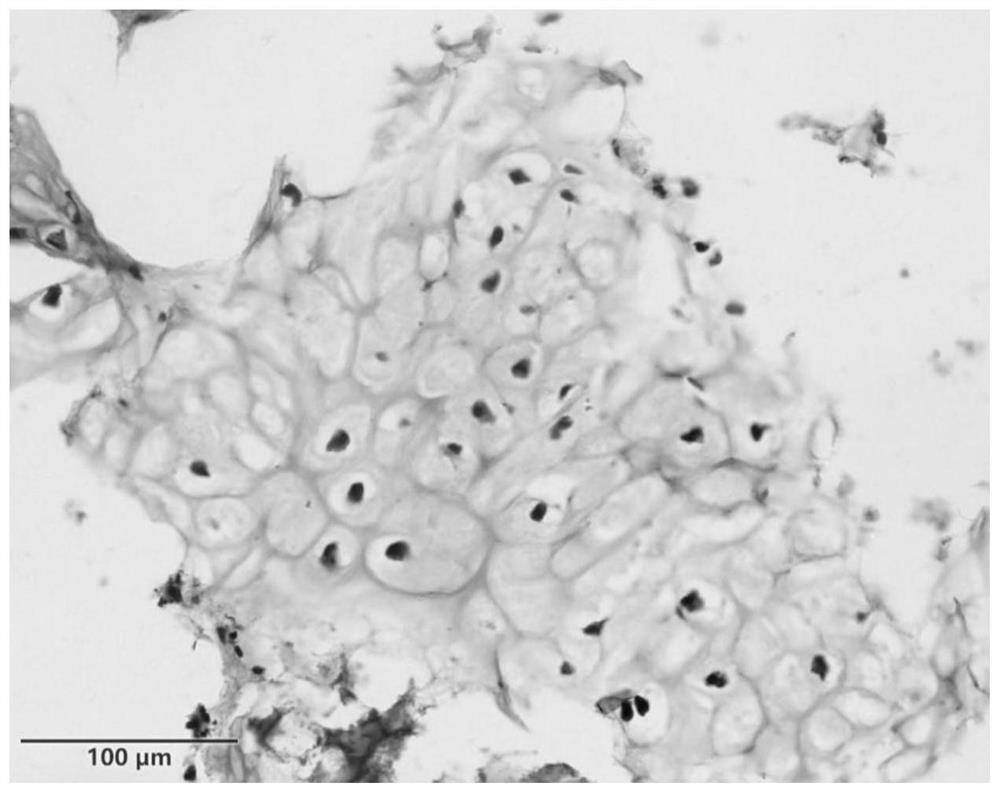

[0049] Embodiment 1: The preparation method of a temperature-sensitive velvet cartilage matrix hydrogel material of the present embodiment is carried out according to the following steps:

[0050] 1. Use a vacuum pump to remove the blood in the antler, then cut the antler skin along the longitudinal direction, and tear off the skin;

[0051] 2. Soak the deer antler treated in step 1 in PBS buffer containing 2U / mL aprotinin, and then place it in a closed pressurizing device (deep-sea seabed water pressure experimental device, Jinan Simingte), at a pressure of 100MPa , the temperature is 30℃ and the pressure is maintained for 15min;

[0052] 3. Cut the deer antler processed in step 2 into 5mm thin slices with a slicer, and then grind it with a bone crusher to a particle size of 0.1 mm to obtain deer antler bone mud;

[0053] 4. ① Put the deer antler bone mud and freeze-thaw buffer (10mM Tris-HCl, 1.5wt% Triton X, pH 8) in a metal airtight container according to the ratio of mat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com