Titanium dioxide photocatalyst and preparation method and application thereof in ceramic tiles

A photocatalyst, titanium dioxide technology, applied in the direction of titanium dioxide, titanium oxide/hydroxide, physical/chemical process catalysts, etc., can solve the problems of easy secondary pollution, inability to remove, slowness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

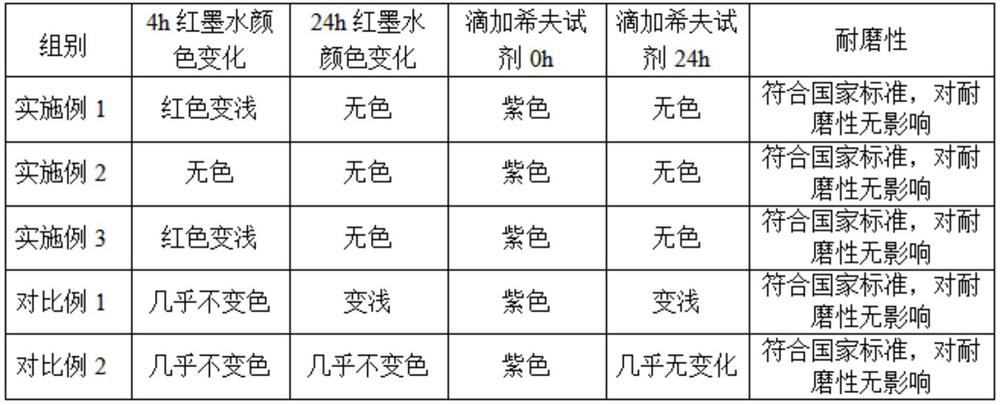

Examples

Embodiment 1

[0023] Add 5g titanium powder to 15ml dilute H 2 SO 4 (H 2 SO 4 : water=1:4), heat and stir until the titanium powder is fully dissolved, add 100ml of deionized water to dilute, adjust the pH value to 7.5 with ammonia water, continue to stir, filter and wash to obtain a solid, and dissolve the obtained solid in 200ml 7.5 g of citric acid was added to deionized water, and while stirring, 10 g of hydrogen peroxide was added, and after stirring for 30 min, the mixture was stirred in a constant temperature water bath at 60° C. for 6 h to obtain titanium dioxide photocatalyst 1 .

[0024] A preparation process for photocatalytic glazed tiles, comprising the following steps:

[0025] 1) The ceramic powder is dry-pressed, the press pressure is 3800T, and the green body layer is obtained, and a layer of 0.3mm top glaze is applied on the green body layer to obtain the top glaze layer, which is dried in a drying kiln at 80°C, and dried Time 50min;

[0026] 2) Using digital inkjet p...

Embodiment 2

[0030] Add 5g titanium powder to 15ml dilute H 2 SO 4 (H 2 SO 4 : water=1:4), heat and stir until the titanium powder is fully dissolved, add 150ml of deionized water to dilute, adjust the pH value to 8 with ammonia water, continue to stir, filter and wash to obtain a solid, and dissolve the obtained solid in 300ml 10 g of citric acid was added into deionized water, and while stirring, 13 g of hydrogen peroxide was added, and after stirring for 30 min, the mixture was stirred in a constant temperature water bath at 60° C. for 7 h to obtain titanium dioxide photocatalyst 2 .

[0031] A preparation process for photocatalytic glazed tiles, comprising the following steps:

[0032] 1) The ceramic powder is dry-pressed, the press pressure is 4000T, and the green body layer is obtained, and a layer of 0.4mm top glaze is applied on the green body layer to obtain the top glaze layer, which is dried in a drying kiln at 100°C, and dried Time 35min;

[0033] 2) Using digital inkjet p...

Embodiment 3

[0037] Add 5g titanium powder to 15ml dilute H 2 SO 4 (H 2 SO 4 : water=1:4), heat and stir until the titanium powder is fully dissolved, add 150ml of deionized water to dilute, adjust the pH value to 8.5 with ammonia water, continue to stir, filter and wash to obtain a solid, and dissolve the obtained solid in 400ml Add 7.5 g of citric acid into deionized water, and while stirring, add 13 g of hydrogen peroxide, stir for 30 min, then stir in a constant temperature water bath at 80° C. for 8 h to obtain titanium dioxide photocatalyst 3 .

[0038] A preparation process for photocatalytic glazed tiles, comprising the following steps:

[0039] 1) The ceramic powder is dry-pressed, the press pressure is 4500T, and the green body layer is obtained, and a layer of 0.5mm top glaze is applied on the green body layer to obtain the top glaze layer, which is dried in a drying kiln at 120°C, and dried Time 30min;

[0040] 2) Using digital inkjet printing technology to print the desig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com