Method for forming nano cellulose film

A nanocellulose and cellulose technology, applied in pharmaceutical formulations, preparations for skin care, cosmetics, etc., can solve problems such as environmental pollution, cellulose degradation, decrease in degree of polymerization and crystallinity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

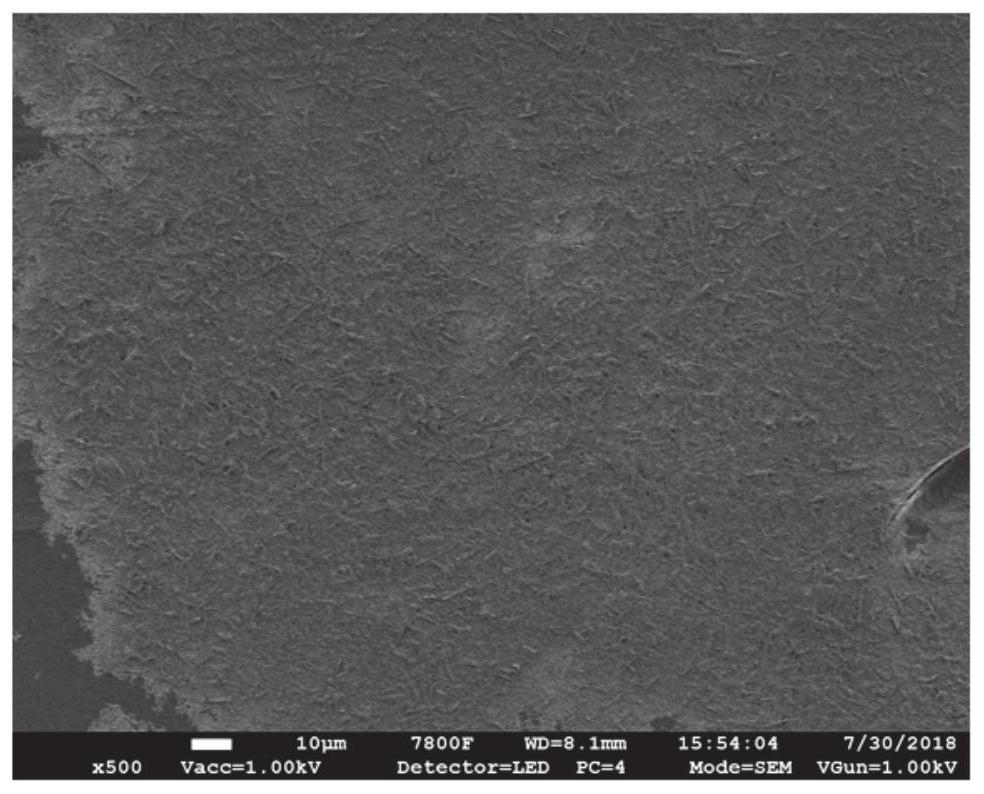

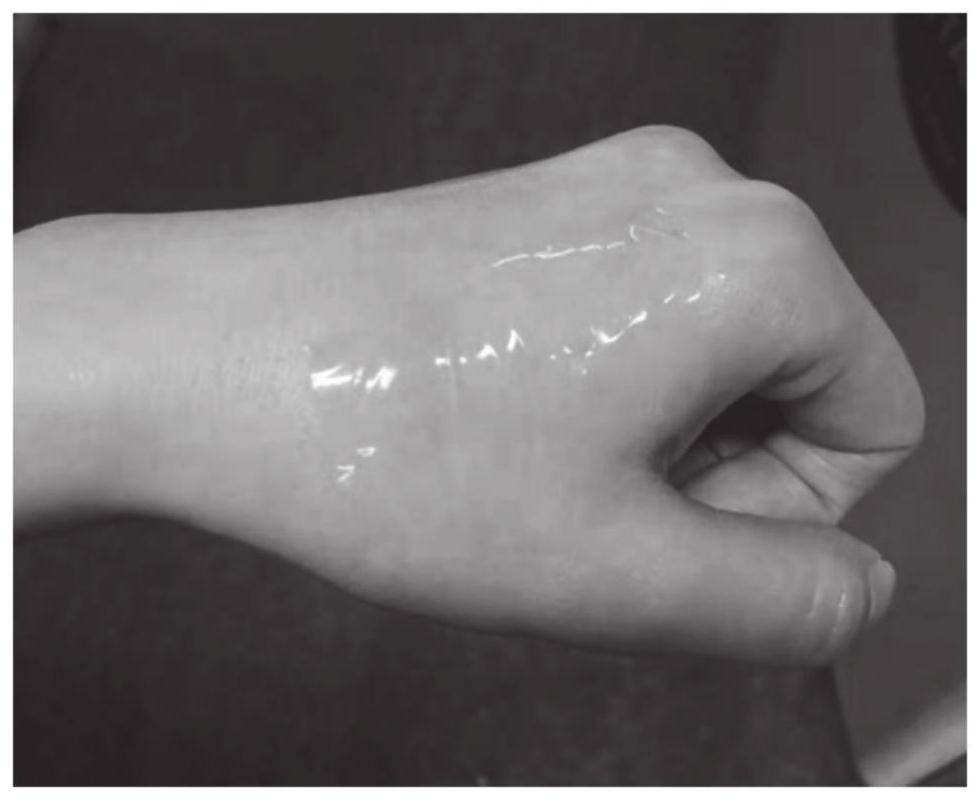

Image

Examples

Embodiment 1

[0029] Grind the nanocellulose of corn stalks, weigh 0.6g of crushed 40-mesh nanocellulose of corn stalks and add it to 25mL of water, imbibition for 5h, separate the solid by suction filtration, then disperse the cellulose raw material with 20mL of acetone, and separate by suction filtration Solids are used to replace the water therein, and acetone needs to be repeatedly replaced and suction filtered twice. Further, the above-mentioned separated solid was added to 10 mL of N,N-dimethylformamide (DMF), stirred for 5 h until the cellulose was fully dispersed to obtain a cellulose solution, and left to stand for 20 h for aging to obtain a casting solution of cellulose. Place the above-prepared casting solution on a smooth and clean glass plate, scrape a film with a thickness of 0.02 cm on the clean glass plate with a scraper, and then put the glass plate into water together with the film to obtain nanocellulose Membrane, labeled #1 Nanocellulose Membrane.

[0030] #1 Characte...

Embodiment 2

[0033] Grind the nanocellulose of corn stalks, weigh 1.9g of the crushed 100-mesh nanocellulose of corn stalks and add it to 55mL of water, imbibition for 2h, separate the solid by suction filtration, then disperse the cellulose raw material with 50mL of acetone, and separate by suction filtration Solids are used to replace the water therein, and acetone needs to be repeatedly replaced and suction filtered 3 times. Further, the above-mentioned separated solid was added to 33 mL of tetrahydrofuran (THF), stirred for 12 h until the cellulose was fully dispersed to obtain a cellulose solution, left to stand for 20 h for aging to obtain a cellulose casting solution, and the above prepared casting solution flow Put it on a smooth and clean glass plate, scrape a film with a thickness of 0.01cm on the clean glass plate with a scraper, and then put the glass plate together with the film into water to obtain a nanocellulose film.

Embodiment 3

[0035] Grind the nanocellulose of corn stalks, weigh 0.5g of crushed 40-mesh nanocellulose of corn stalks, add it to 15mL of water, imbibe for 2h, separate the solid by suction filtration, then disperse the cellulose raw material with 10mL of methanol, and separate by suction filtration Solids are used to replace the water therein, and methanol needs to be repeatedly replaced and suction filtered 3 times. Further, add the above-mentioned separated solid into a mixed system containing 0.8g lithium chloride (LiCl) and 10mL N,N-dimethylacetamide (DMAC), stir for 12h until the cellulose is fully dispersed to obtain a cellulose solution, and let stand for 10h to proceed Aging to obtain the casting solution of cellulose, place the above-mentioned casting solution flow on a smooth and clean glass plate, scrape a film with a thickness of 0.01cm on the clean glass plate with a scraper, and then connect the glass plates The membranes are put into water together to obtain the nanocellulo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com