Composite solid electrolyte film based on NASICON type electrolyte and preparation method thereof

A solid electrolyte and electrolyte technology, applied in non-aqueous electrolyte batteries, solid electrolytes, non-aqueous electrolytes, etc., can solve the problems of poor compatibility, large room temperature polarization, and low ionic conductivity of polymer-based solid electrolytes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

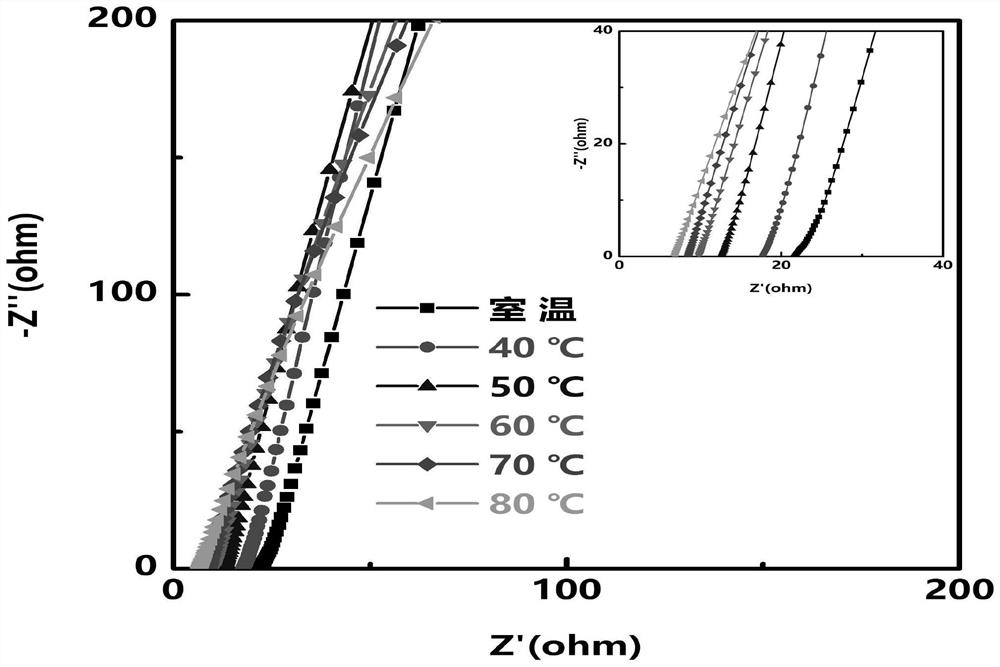

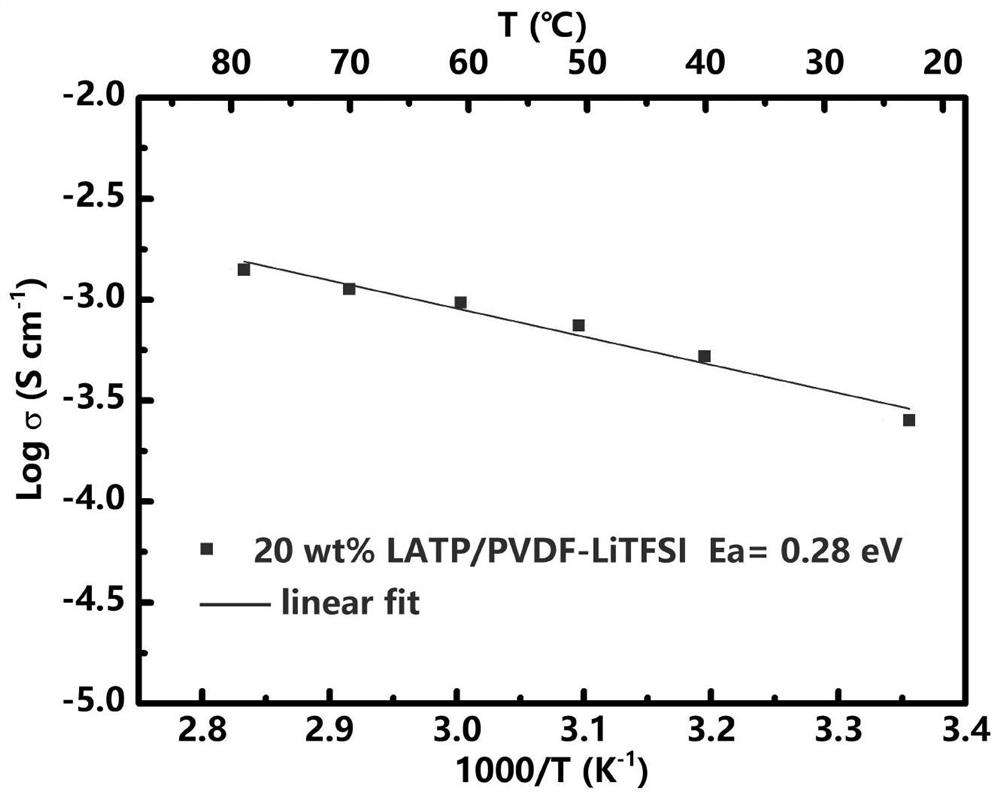

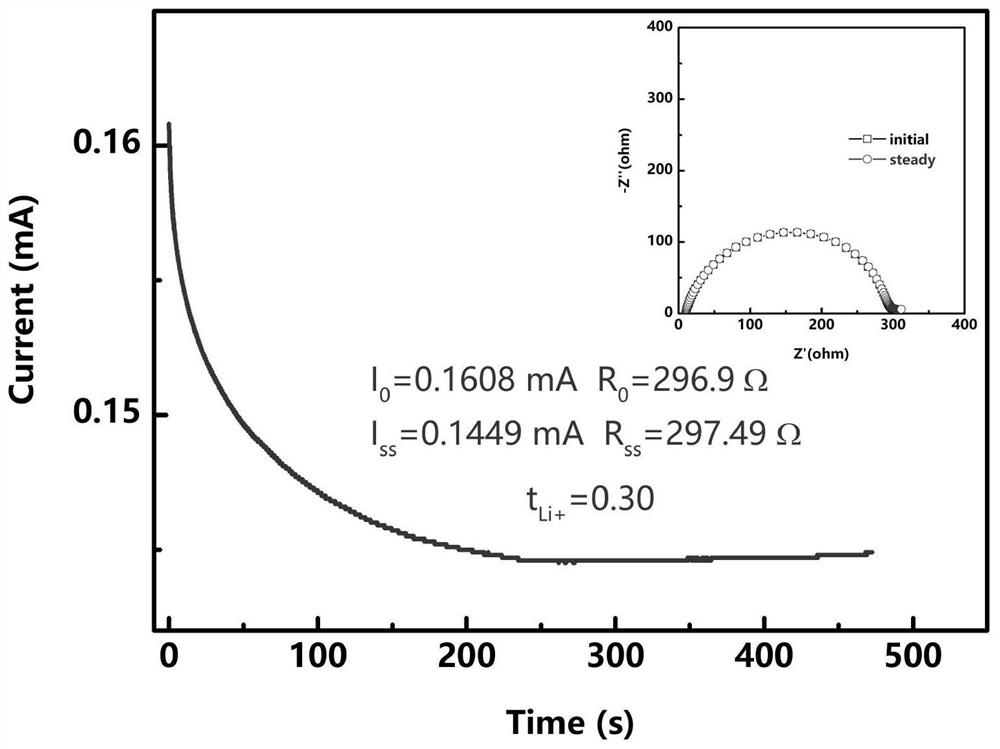

[0048] Specific embodiment one: a kind of composite solid electrolyte film based on NASICON type electrolyte of the present embodiment is made of 0.2g Li 1.3 al 0.3 Ti 1.7 (PO 4 ) 3 (LATP) solid electrolyte powder, 0.6g of PVDF and 0.2g of LiTFSI were prepared by solution casting method.

[0049] The method for preparing the composite solid electrolyte film based on NASICON type electrolyte as described in the first embodiment is carried out in the following steps:

[0050] 1. Add 0.2g of Li 1.3 al 0.3 Ti 1.7 (PO 4 ) 3 (LATP) Ultrasonic dispersion of solid electrolyte powder in 2mL of N,N-dimethylformamide, ultrasonic 10h, to obtain a solid electrolyte dispersion;

[0051] 2. ①In a stirring state, add 0.6g of PVDF (molecular weight Mw=400000g / mol) into 3mL of N,N-dimethylformamide, heat and stir at 60°C for 12h to obtain a polymer solution;② Under stirring, add 0.2g of LiTFSI to 1mL of N,N-dimethylformamide, heat and stir at 60°C for 6h to obtain a lithium salt solut...

specific Embodiment approach 2

[0060] Specific embodiment two: a kind of composite solid electrolyte film based on NASICON type electrolyte of the present embodiment is made of 0.2g Li 1.3 al 0.3 Ti 1.7 (PO 4 ) 3 (LATP) solid electrolyte powder, 0.6g of PVDF-HFP and 0.2g of LiTFSI were prepared by solution casting method.

[0061] The method for preparing the composite solid electrolyte film based on the NASICON type electrolyte as described in the second embodiment is carried out in the following steps:

[0062] 1. Add 0.2g of Li 1.3 al 0.3 Ti 1.7 (PO 4 ) 3 (LATP) Ultrasonic dispersion of solid electrolyte powder in 2mL of N,N-dimethylformamide, ultrasonic 10h, to obtain a solid electrolyte dispersion;

[0063] 2. ① Under stirring, add 0.6g of PVDF-HFP (molecular weight Mw=400000g / mol) into 3mL of N,N-dimethylformamide, heat and stir at 60°C for 12h to obtain a polymer solution ; ②Under stirring, add 0.2g of LiTFSI to 1mL of N,N-dimethylformamide, heat and stir at 60°C for 6h to obtain a lithium ...

specific Embodiment approach 3

[0067] Specific embodiment three: a kind of composite solid electrolyte film based on NASICON type electrolyte of the present embodiment is made of 0.25g Li 1.3 al 0.3 Ti 1.7 (PO 4 ) 3 (LATP) solid electrolyte powder, 0.6g of PVDF and 0.4g of LiTFSI were prepared by solution casting method.

[0068] The method for preparing the composite solid electrolyte film based on the NASICON type electrolyte as described in the third embodiment is carried out in the following steps:

[0069] 1. Add 0.25g of Li 1.3 al 0.3 Ti 1.7 (PO 4 ) 3 (LATP) Ultrasonic dispersion of solid electrolyte powder in 2.5mL of N,N-dimethylformamide, ultrasonic 10h, to obtain a solid electrolyte dispersion;

[0070] 2. ①In a stirring state, add 0.6g of PVDF (molecular weight Mw=400000g / mol) into 3mL of N,N-dimethylformamide, heat and stir at 60°C for 12h to obtain a polymer solution;② Under stirring, add 0.4g of LiTFSI to 2mL of N,N-dimethylformamide, heat and stir at 60°C for 6h to obtain a lithium ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com