Method for reducing sulfur content of nickel-cobalt-manganese ternary positive electrode material precursor

A cathode material and precursor technology, applied in the field of reducing the sulfur content of nickel-cobalt-manganese ternary cathode material precursors, can solve the problem of corrosion of production equipment, poor removal effect, influence of NCM structural stability, crystallinity and unit cell parameters, etc. problems, to achieve the effect of reducing pollution, reducing the amount of washing water, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

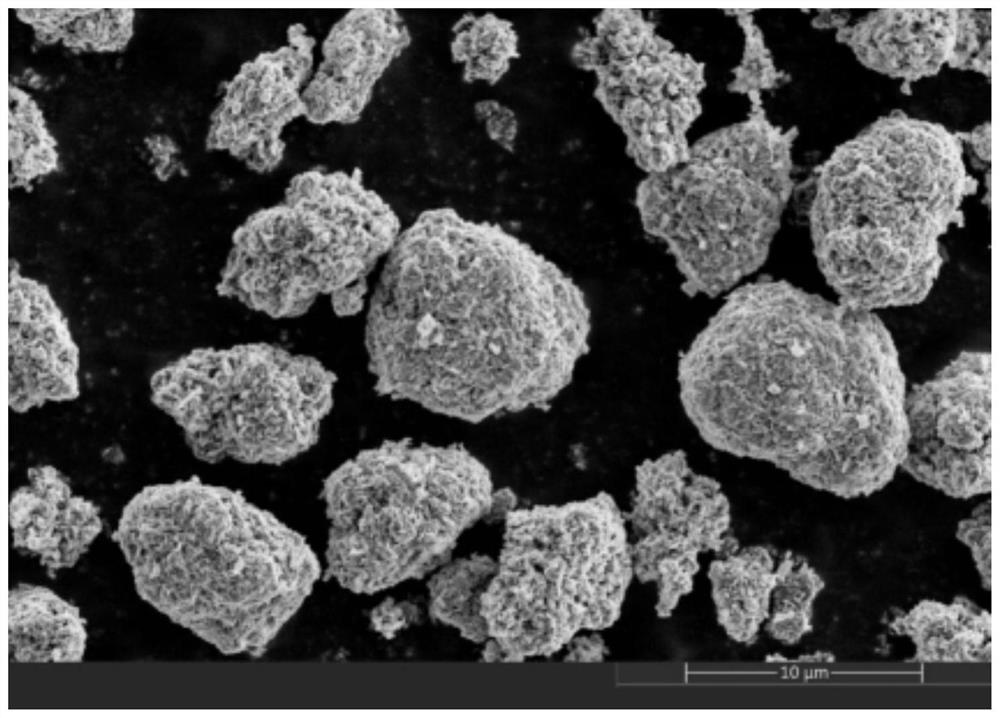

Embodiment 1

[0047] A method for reducing the sulfur content of the precursor of the nickel-cobalt-manganese cathode material includes the following steps:

[0048] (1) Combine a mixed solution of nickel, cobalt and manganese with a nickel content of 47.45g / L, a cobalt content of 18.8g / L, and a manganese content of 26.4g / L, and 400g / L sodium hydroxide and 8% ammonia water. At the same time, it is transported to the reactor by a metering pump, and high-purity nitrogen is introduced into the reactor. The temperature in the reactor is controlled at 65~70℃, pH is 10.5~11, and the ammonia value is in the range of 5~8g / L. After the particle size D50 of the precursor in the reactor reaches 10 microns, the precursor slurry is obtained;

[0049] (2) Transfer the precursor slurry to the aging tank for aging for 5 hours, and then transfer it to the plate and frame filter press, and pass the sodium hydroxide hot solution twice to wash the SO adsorbed on the surface of the precursor particles. 4 2- , The fi...

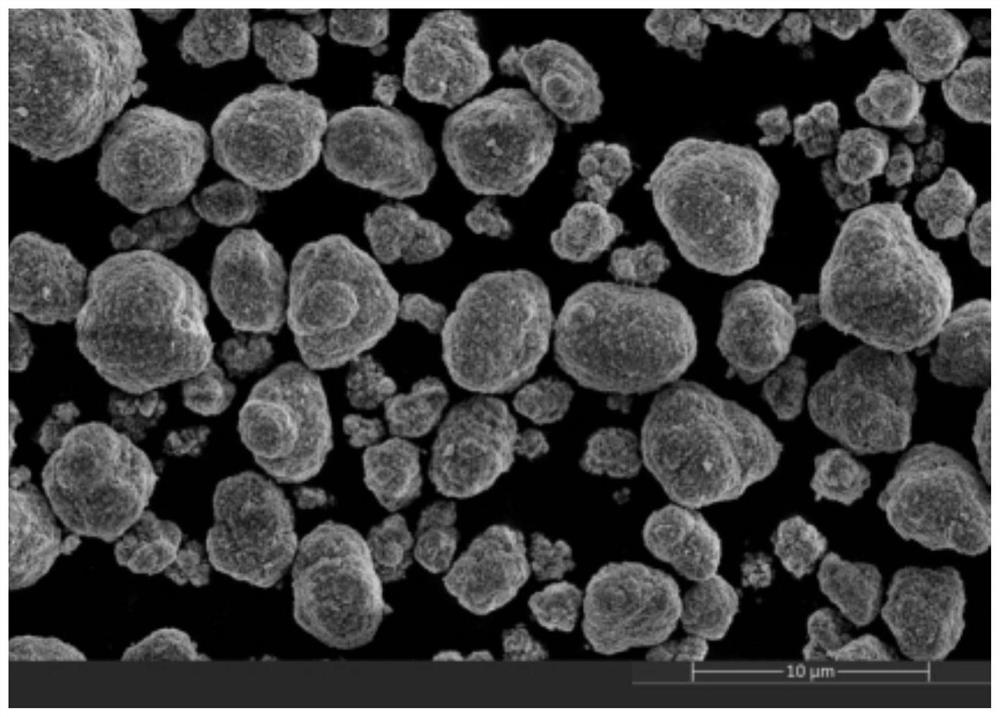

Embodiment 2

[0054] A method for reducing the sulfur content of the precursor of the nickel-cobalt-manganese cathode material includes the following steps:

[0055] (5) Combine a nickel-cobalt-manganese metal mixed solution with a nickel content of 56.5g / L, a cobalt content of 18.8g / L, and a manganese content of 17.5g / L with 400g / L sodium hydroxide and 8% mass fraction of ammonia At the same time, it is transported to the reactor by a metering pump, and high-purity nitrogen is introduced into the reactor. The temperature in the reactor is controlled at 65~70℃, the pH is 11-11.5, and the ammonia value is within the range of 4-5g / L. After the particle size D50 of the precursor in the reactor reaches 10.5 microns, the precursor slurry is obtained;

[0056] (6) Transfer the precursor slurry to the aging tank for aging for 5 hours, and then transfer it to the plate and frame filter press, and pass the sodium hydroxide hot solution twice to wash the SO adsorbed on the surface of the precursor particl...

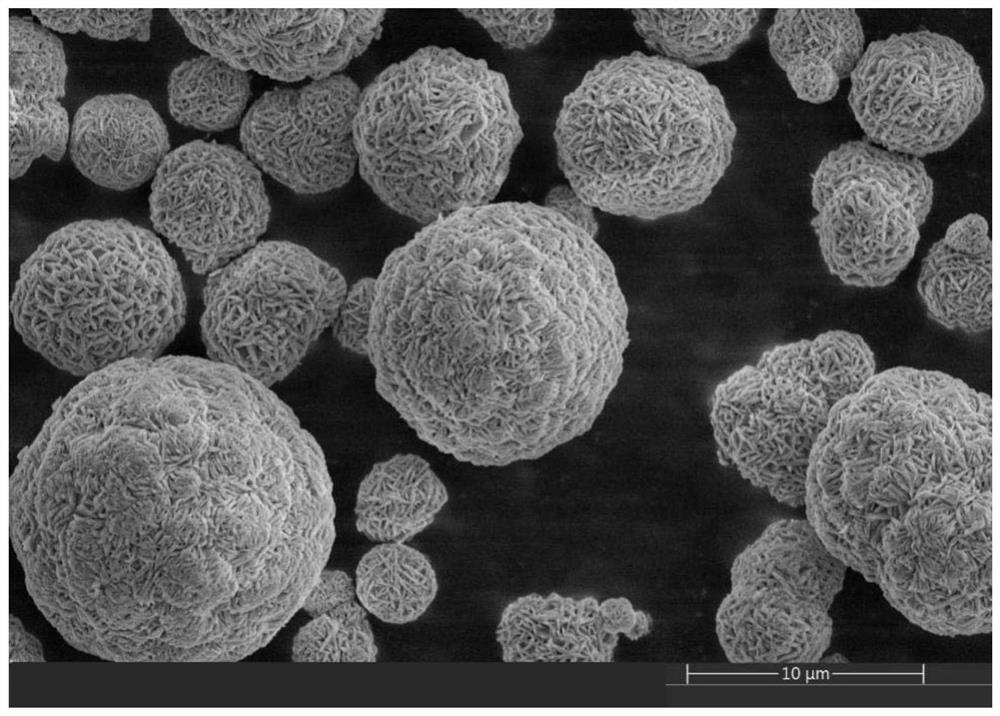

Embodiment 3

[0061] A method for reducing the sulfur content of the precursor of the nickel-cobalt-manganese cathode material includes the following steps:

[0062] (1) Combine a nickel-cobalt-manganese metal mixed solution with a nickel content of 77.94g / L, a cobalt content of 10.37g / L, and a manganese content of 5.27g / L with 400g / L sodium hydroxide and 8% mass fraction of ammonia At the same time, it is transported to the reactor by a metering pump, and high-purity nitrogen is introduced into the reactor, and then the temperature in the reactor is controlled at 65-70°C, the pH is 10.5-11, and the ammonia value is within the range of 2.5-5g / L. When the particle size D50 of the precursor in the reactor reaches 9 microns, the precursor slurry is obtained;

[0063] (2) Transfer the precursor slurry to the aging tank for aging for 2-12 hours, and then transport it to the plate and frame filter press, and pass the sodium hydroxide hot solution twice to wash the adsorbed on the surface of the precur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tap density | aaaaa | aaaaa |

| Tap density | aaaaa | aaaaa |

| Tap density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com