Fermentation method and device for preparing monosodium glutamate from sweet potatoes

A fermentation method, sweet potato technology, applied in sterilization methods, specific-purpose bioreactors/fermenters, microorganism-based methods, etc., can solve problems such as low efficiency and poor effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

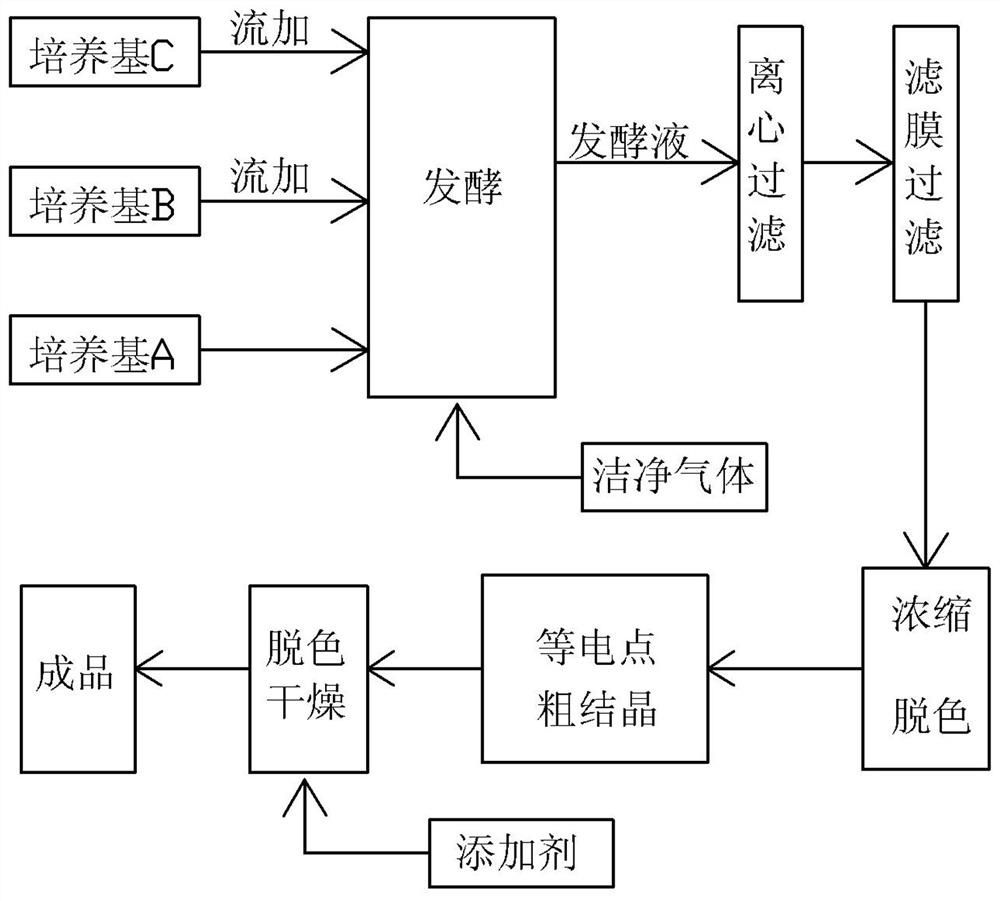

[0029] Embodiment 1, according to figure 1 , a kind of fermentation method utilizing sweet potato to prepare monosodium glutamate, it comprises the steps:

[0030] Step 1) preparation of fermentation medium, step 2) fermentation culture, step 3) filtration and concentration, step 4) crystallization, and step 5) preparation of monosodium glutamate.

[0031] Specifically, step 1) preparing a fermentation medium, which includes fermentation medium A, fermentation medium B and fermentation medium C used separately;

[0032] The fermentation medium A includes (by mass ratio): sweet potato glucose 15%, sweet potato galactose 2.5%, urea 0.2%, ferrous sulfate 0.02%, magnesium sulfate 0.01%, potassium sulfate 0.02%, polyether modified silicone oil 0.02% %, potassium dihydrogen phosphate 0.15%, ammonium dihydrogen phosphate 0.05% and biotin 0.05%, sodium bicarbonate 0.5%, and the rest is water;

[0033] Fermentation medium B includes (by mass ratio): urea 11.5%, phenylalanine 0.5% and...

Embodiment 2

[0039] Embodiment 2, a kind of fermentation method utilizing sweet potato to prepare monosodium glutamate, comprises:

[0040]Step 1) preparing a fermentation medium, which includes fermentation medium A, fermentation medium B and fermentation medium C used separately;

[0041] The fermentation medium A includes (by mass ratio): 12% sweet potato glucose, 5% sweet potato galactose, 0.2% urea, 0.02% ferrous sulfate, 0.01% magnesium sulfate, 0.02% potassium sulfate, 0.02% glycerol, diphosphate Potassium hydrogen 0.15%, ammonium dihydrogen phosphate 0.05% and biotin 0.05%, sodium carbonate 0.5%, the rest is water;

[0042] Fermentation medium B includes (by mass ratio): 30% ammonia water, 0.5% phenylalanine and 0.2% defoamer;

[0043] Fermentation medium C includes (by mass ratio): 20% sweet potato glucose, 8% sweet potato galactose, 0.15% biotin, and 1.5% sodium bicarbonate.

[0044] Step 2) Fermentation culture, sterilize the fermentation medium A, put it in a fermenter, adjus...

Embodiment 3

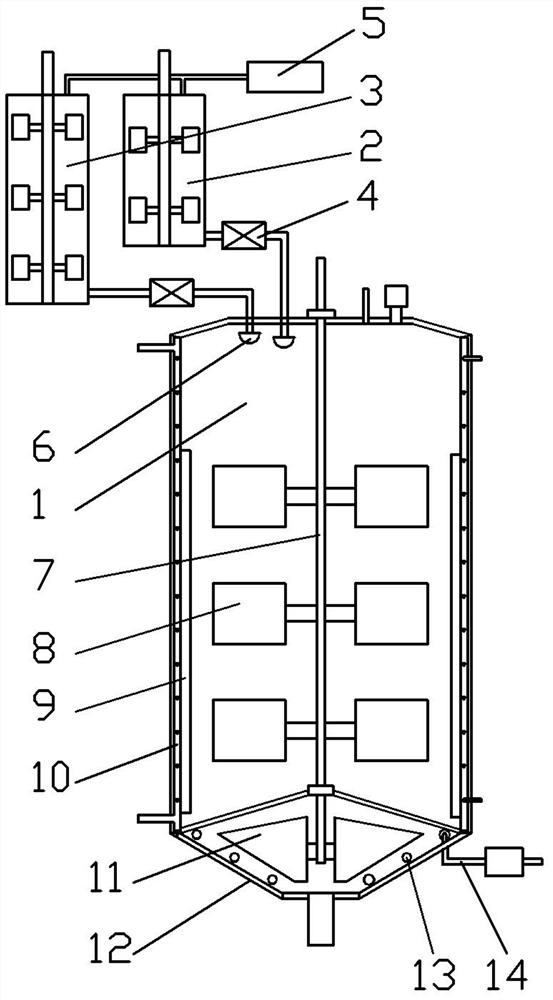

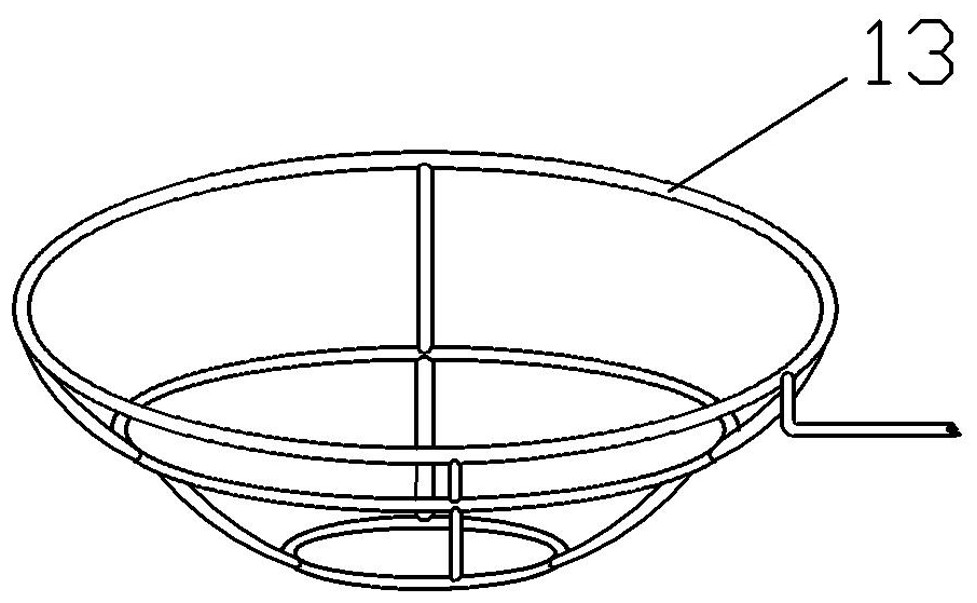

[0049] Embodiment 3, according to Figure 1-Figure 3 , a fermentation device utilizing sweet potato to prepare monosodium glutamate comprises fermentation equipment, filtering equipment and crystallization equipment, wherein the fermentation equipment comprises a fermenter 1; a stirring shaft 7 and an upper stirring blade 8 are arranged in the fermenter, and in the side wall of the fermenter An interlayer 10 with a circulating medium is provided; the top is connected to the stirring tank I2 and the stirring tank II3 respectively through pipelines; the bottom of the fermenter is a conical bottom 12, and an aeration tank close to or fitted to the conical bottom is provided. Pipe 13; vertical strips 9 are arranged on the inner side wall of the fermenter.

[0050] The stirring tank I and the stirring tank II are provided with a stirring device and a temperature control device; the pipelines of the stirring tank I and the stirring tank II are provided with a solenoid valve 4, and a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com