Composite solid electrolyte membrane, preparation method thereof and lithium ion battery

A solid-state electrolyte membrane and electrolyte technology, applied in the field of lithium-ion batteries, can solve problems such as inability to meet requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] Embodiment 1 proposes a composite solid electrolyte membrane, which is prepared by the following method:

[0056] (1) 18 parts by weight of Li 6 P.S. 5 Cl (average particle size is about 10nm), 17 parts by weight polystyrene (average molecular weight is about 320,000), 5 parts by weight of dinitrosopentamethylenetetramine, and 60 parts by weight of toluene are prepared into a spinning stock solution.

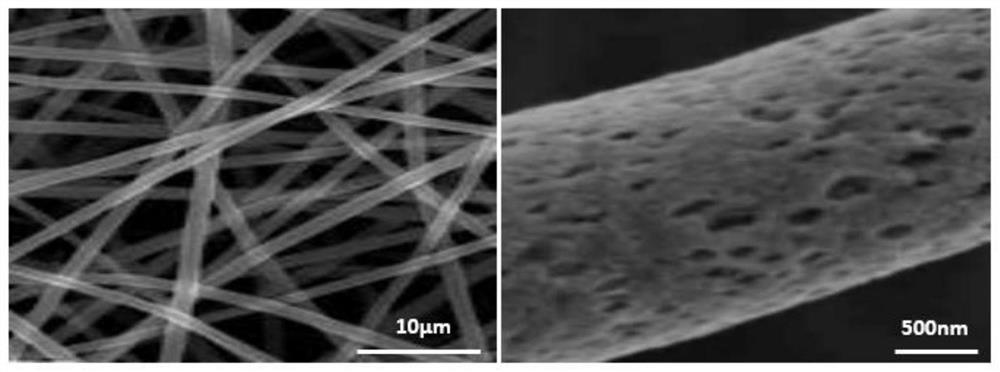

[0057] (2) Electrospinning the spinning stock solution to obtain a composite fiber with a diameter of about 150nm, wherein the spinning parameters are set as follows: the diameter of the spinning needle tube is about 200nm, the voltage is about 40kV, the receiving distance is about 40cm, and the solution flow rate About 1mL / h.

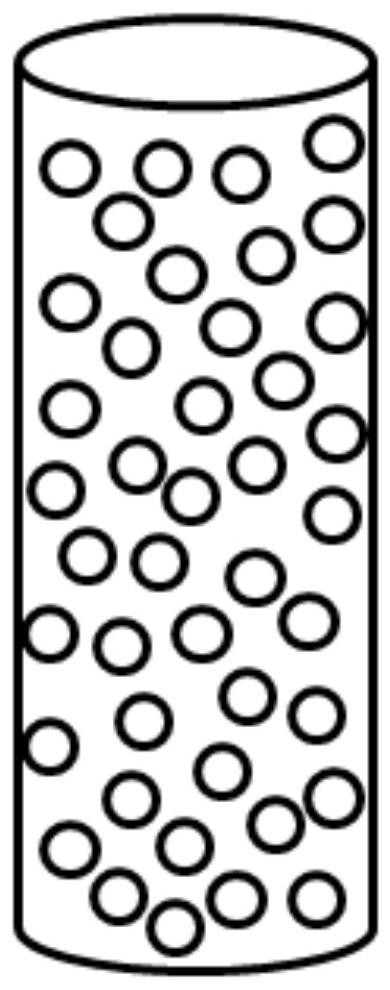

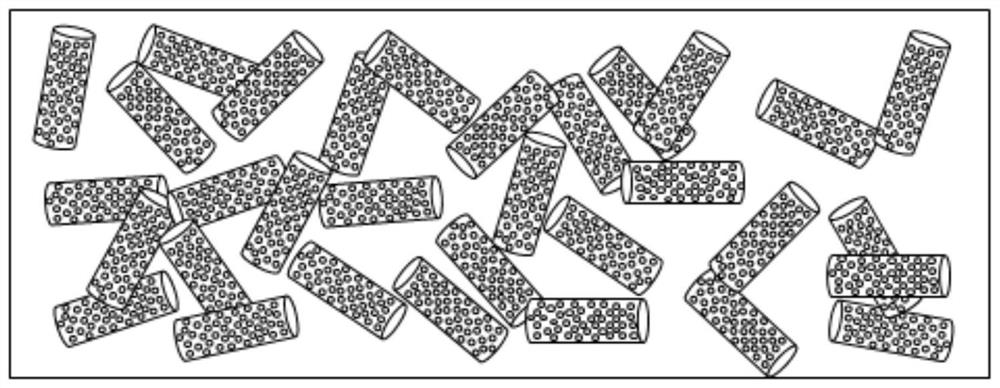

[0058](3) Calcining the composite fiber at about 550° C. for about 12 hours, and then treating the above composite fiber with a high-speed shear to obtain an inorganic electrolyte porous fiber with an average length of about 5 μm, such as figur...

Embodiment 2

[0061] Embodiment 2 proposes a composite solid electrolyte membrane, which is prepared by the following method:

[0062] (1) 15 parts by weight of Li 2 Ti 3 o 7 (the average particle diameter is about 50nm), 10 parts by weight of polyvinylidene fluoride (average molecular weight is about 1 million), 3 parts by weight of diisopropyl azodicarboxylate, and 72 parts by weight of NMP to prepare the spinning stock solution.

[0063] (2) Electrospinning the spinning stock solution to obtain a composite fiber with a diameter of about 400nm, wherein the spinning parameters are set as follows: the diameter of the spinning needle tube is about 400nm, the voltage is about 45kV, the receiving distance is about 50cm, and the solution flow rate About 1mL / h.

[0064] (3) Calcining the composite fiber at about 920° C. for about 1 h, and then treating the composite fiber with a high-speed shearing machine to obtain an inorganic electrolyte porous fiber with an average length of about 5 μm. ...

Embodiment 3

[0067] Embodiment 3 proposes a composite solid electrolyte membrane, which is prepared by the following method:

[0068] (1) 22 parts by weight of Li 1.4 al 0.4 Ti 1.6 (PO 4 ) 3 (the average particle diameter is about 750nm), 7 parts by weight of polyvinylpyrrolidone (average molecular weight is about 420,000), 1 part by weight of azodicarbonamide, and 80 parts by weight of ethanol are prepared into a spinning stock solution.

[0069] (2) Electrospinning the spinning stock solution to obtain a composite fiber with a diameter of about 9000nm, wherein the spinning parameters are set as follows: the diameter of the spinning needle tube is about 9000nm, the voltage is about 40kV, the receiving distance is about 55cm, and the solution flow rate About 1mL / h.

[0070] (3) Calcining the composite fiber at about 1200° C. for about 0.5 h, and then using a high-speed shear to process the composite fiber to obtain an inorganic electrolyte porous fiber with an average length of about ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com