High-voltage polymer electrolyte and preparation method of solid-state battery thereof

A solid-state battery and polymer technology, applied in the manufacture of electrolyte batteries, non-aqueous electrolyte batteries, secondary batteries, etc., can solve problems such as potential safety hazards, unstable cycle performance, and high pressure resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035]Embodiments of the present invention provide a method for preparing a high-voltage polymer electrolyte, comprising the following steps:

[0036] (1) Dissolving the polymer in the solvent at room temperature or by heating, the temperature during heating is 25-120°C;

[0037] (2) Dissolving a certain proportion of lithium salt in the above mixture, the quality of the lithium salt accounts for 100% to 200% of the polymer mass;

[0038] (3) Add the high-voltage additive to the mixture, stir evenly, and then cast the mixture to form a film or coat it on the diaphragm, heat and dry it with air blast to obtain a high-voltage resistant composite high-voltage polymer electrolyte; wherein, the high-voltage additive The mass of the polymer accounts for 1% to 10% of the polymer mass.

[0039] Preferably, in the step (3), after adding the high-voltage additive, an inorganic filler can be added, and the mixture is stirred for 5-24 hours; the mass of the inorganic filler accounts for ...

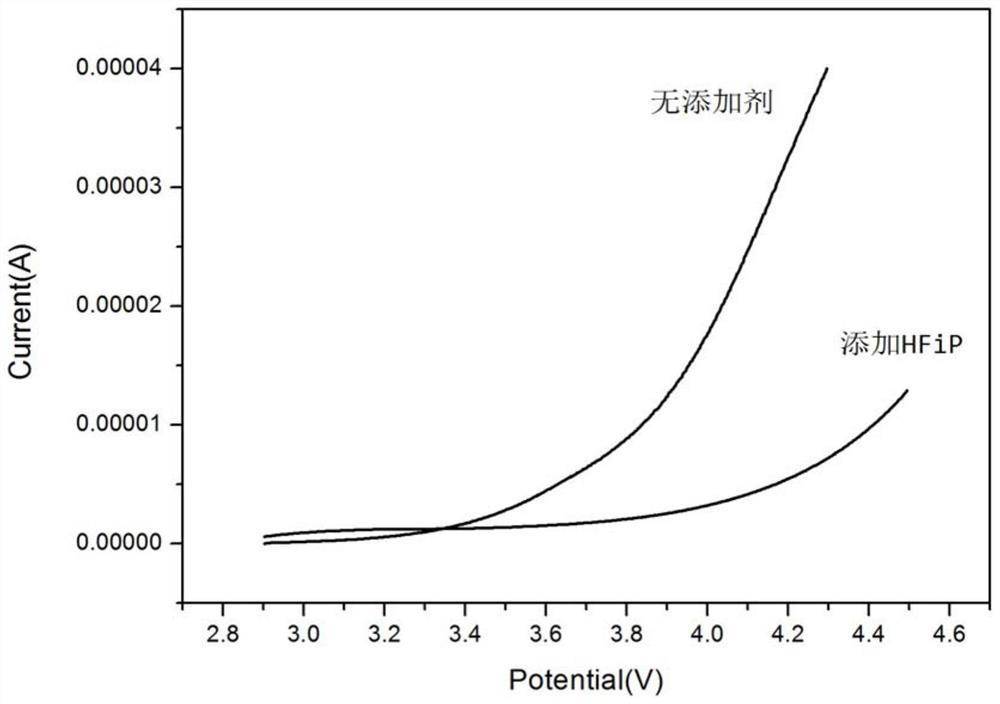

Embodiment 1

[0054] Preparation of high-voltage polymer electrolyte: Dissolve 4g polypropylene carbonate (PPC) and 0.8g polyvinylidene fluoride-hexafluoropropylene (PVDF-HFP) in NMP, and heat to dissolve at 60°C. Add 6.5 g of lithium bis(trifluoromethylsulfonyl)imide (LiTFSI) into the mixed solution, and stir for 1 h. Add 0.1g of tris(hexafluoro-isopropyl) phosphate (HFiP) into the mixed solution, stir for 12 hours, pour the mixed solution on a polytetrafluoroethylene board to form a film, blow air, heat and dry, and obtain a high-voltage resistant composite high-voltage polymer electrolyte membrane.

[0055] Preparation of positive and negative pole pieces: Mix 9g LiFePO4 with 0.5g conductive agent SP, add 0.5g PVDF and 40ml NMP, stir for 3 hours to obtain positive electrode slurry, apply on aluminum foil, dry at 100°C for 1 hour, roll press, divide Cut to prepare the positive electrode sheet. Mix 9g of graphite with 0.5g of conductive agent SP, add 0.5g of PVDF and 40ml of NMP, stir fo...

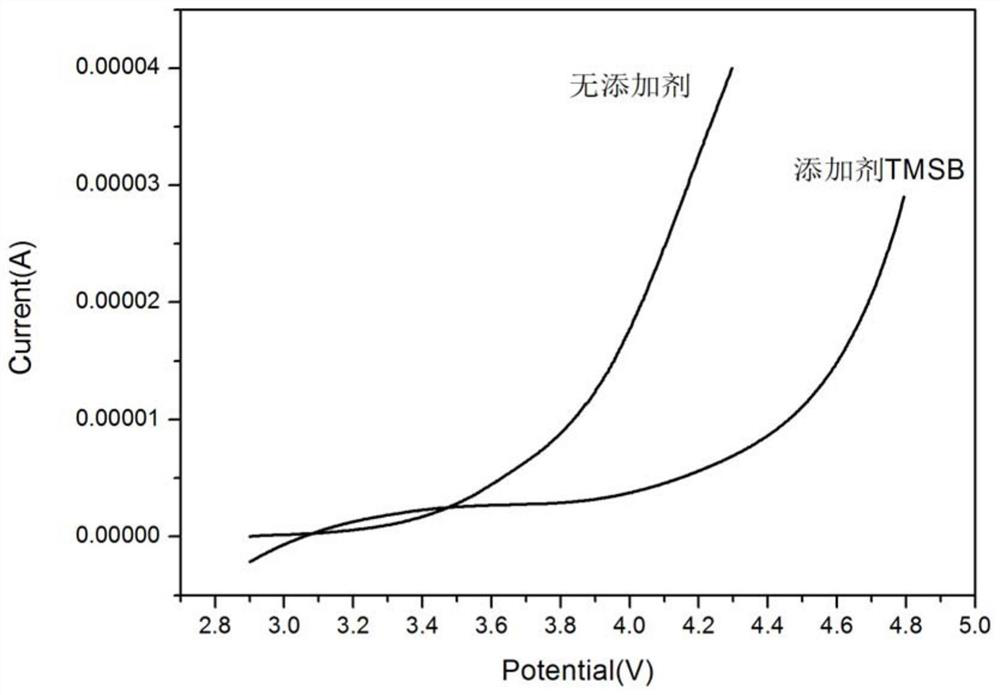

Embodiment 2

[0058] Preparation of high-voltage polymer electrolyte: Dissolve 4g polypropylene carbonate (PPC) and 0.8g polyvinylidene fluoride-hexafluoropropylene (PVDF-HFP) in NMP, and heat to dissolve at 60°C. Add 6.5 g of lithium bis(trifluoromethylsulfonyl)imide (LiTFSI) into the mixed solution, and stir for 1 h. Add 0.1g tris(trimethylsilane) borate (TMSB) into the mixed solution, then add 0.48g inorganic filler aluminum oxide (Al2O3), stir for 12h, pour the mixed solution on a polytetrafluoroethylene plate to form The membrane is heated and dried by blowing air to obtain a high-voltage resistant composite high-voltage polymer electrolyte membrane.

[0059] Preparation of positive and negative electrodes: Mix 9g LiCoO2 with 0.5g conductive agent SP, add 0.5g PVDF and 40ml NMP, stir for 3 hours to obtain positive electrode slurry, apply on aluminum foil, dry at 100°C for 1 hour, roll press, Slitting and preparing positive pole pieces. Mix 9g of graphite with 0.5g of conductive agent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com