Alcohol liquid phase reforming hydrogen production catalyst, preparation method and application thereof

A liquid-phase reforming and catalyst technology, which is applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, etc., can solve the problems of land occupation, high input cost and high operating cost. Problems such as high volume load of the aeration tank and high energy consumption of distillation and separation achieve the effect of improving conversion rate and hydrogen selectivity, high conversion rate and high hydrogen selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

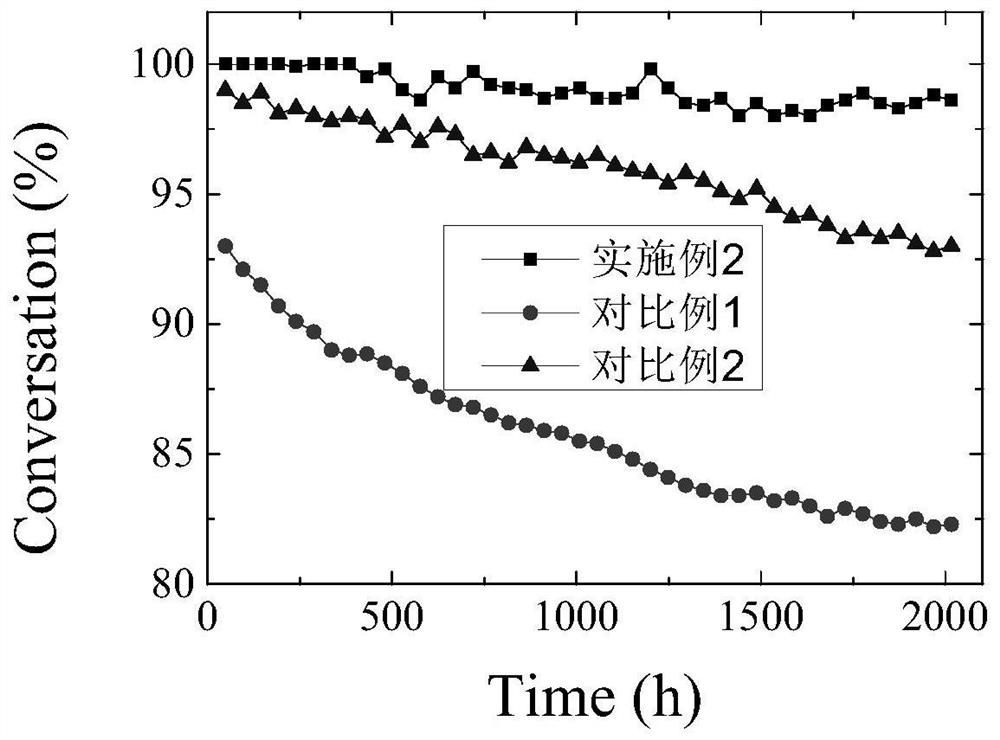

Embodiment 1

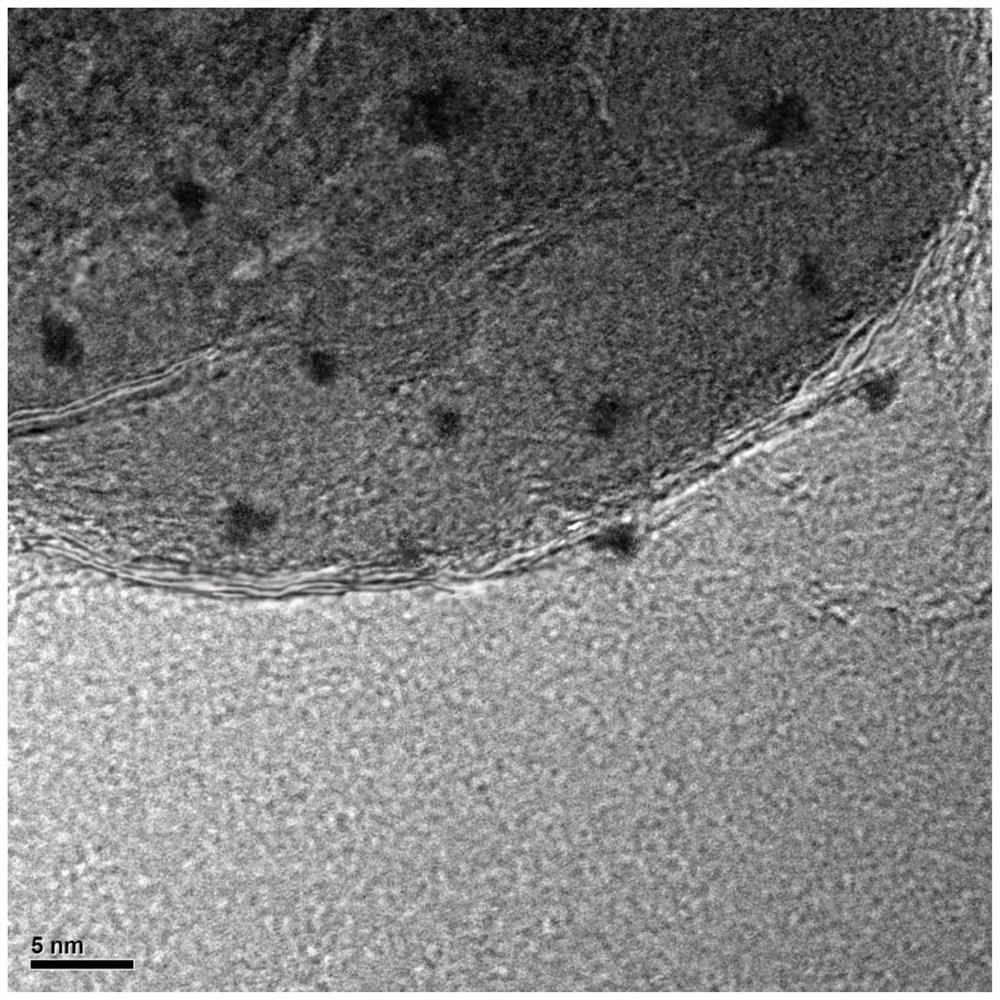

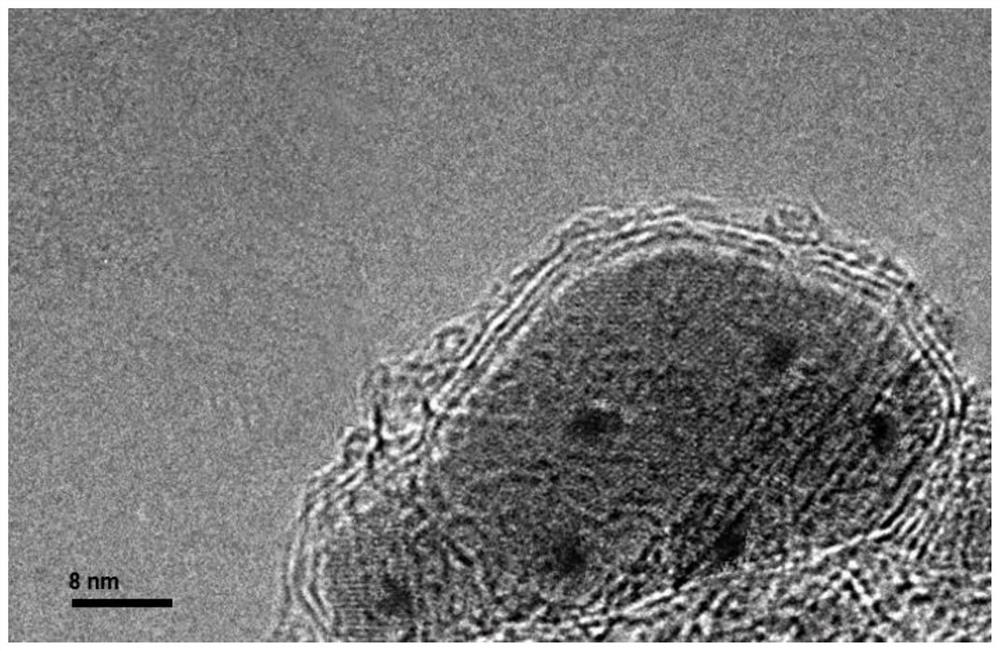

[0053] 10.0 g of magnesium oxide powder was mixed with 100.0 g of deionized water and stirred for 2 hours using ultrasound. Then pour into the condensing reflux device and continue to boil for 24 hours. After filtration, the product was heated in a furnace at 500° C. for 5 hours to completely remove the moisture. The magnesia powder was placed in a CVD tube furnace, and Ar gas was introduced to maintain the absolute pressure in the tube furnace at 0.02 MPa. After the temperature was raised to 900°C and stabilized for 10 minutes, methane was introduced at a flow rate of 20 ml / min for 5 minutes, and then the methane was stopped and the temperature was naturally lowered immediately. Graphene just grows on the magnesia surface, and the product obtained is added dropwise to distilled water to incipient wetness, and the volume of consumed water is recorded, and then accounts for 3.0% by weight of the overall catalyst mass by Pt content (in oxides), and the preparation of four Ammo...

Embodiment 2

[0055] 10.0 g of magnesium oxide powder was mixed with 100.0 g of deionized water and stirred for 2 hours using ultrasound. Then pour into the condensing reflux device and continue to boil for 24 hours. After filtration, the product was heated in a furnace at 500° C. for 5 hours to completely remove the moisture. The magnesia powder was placed in a CVD tube furnace, and Ar gas was introduced to maintain the absolute pressure in the tube furnace at 0.02 MPa. After the temperature was raised to 900°C and stabilized for 10 minutes, methane was introduced at a flow rate of 20 ml / min for 5 minutes, and then the methane was stopped and the temperature was naturally lowered immediately. Graphene just grows on the magnesia surface, and the product obtained is dripped with distilled water to incipient wetness, records the volume of consumed water, then accounts for 25% by weight of the overall catalyst mass by Ni content (in oxides), and prepares nitric acid Nickel impregnating solut...

Embodiment 3

[0058] After mixing 5.0 g of magnesium oxide powder and 5.0 g of aluminum oxide powder, add 100.0 g of deionized water and mix, and use ultrasonic stirring for 2 hours. Then pour into the condensing reflux device and continue to boil for 24 hours. After filtration, the product was heated in a furnace at 500° C. for 5 hours to completely remove the moisture. The magnesia powder was placed in a CVD tube furnace, and Ar gas was introduced to maintain the absolute pressure in the tube furnace at 0.02 MPa. After the temperature was raised to 900°C and stabilized for 10 minutes, methane was introduced at a flow rate of 5 ml / min for 5 minutes, then the methane was stopped and the temperature was naturally lowered immediately. Graphene just grows on the magnesia surface, and the product obtained is dripped with distilled water to incipient wetness, records the volume of consumed water, then accounts for 25% by weight of the overall catalyst mass by Ni content (in oxides), and prepare...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com