Novel magnetorheological elastomer based on dynamic polymer matrix and preparation method

A magnetorheological elastomer and polymer technology, applied in the field of magnetorheological smart materials and dynamic polymers, can solve problems such as difficulty in controlling the degree of polymerization reaction and difficulty in controlling the composite structure of composite materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] A novel magnetorheological elastomer based on dynamic polymer matrix polyimine and a preparation method thereof include the following steps:

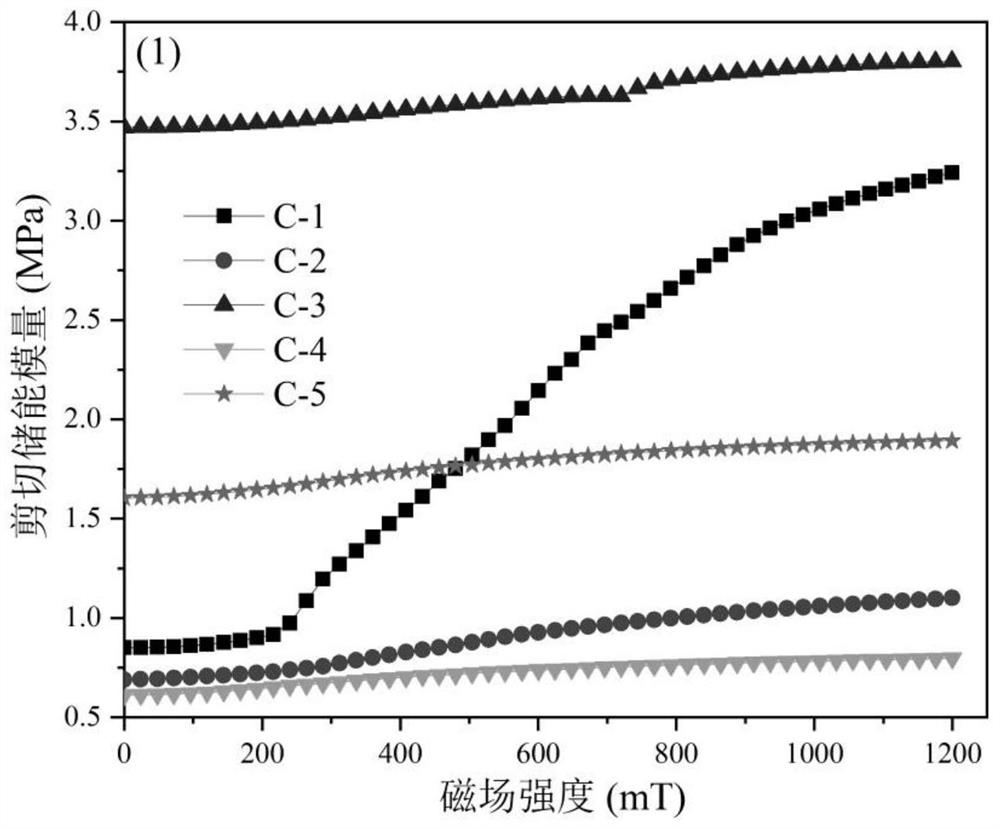

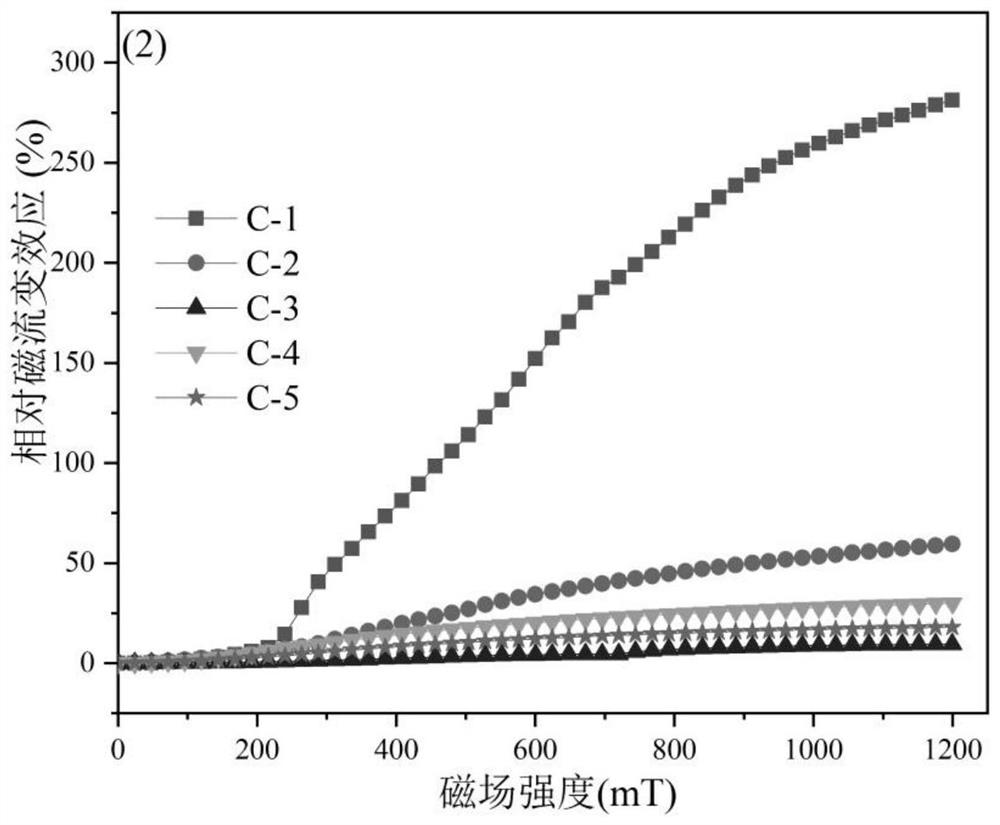

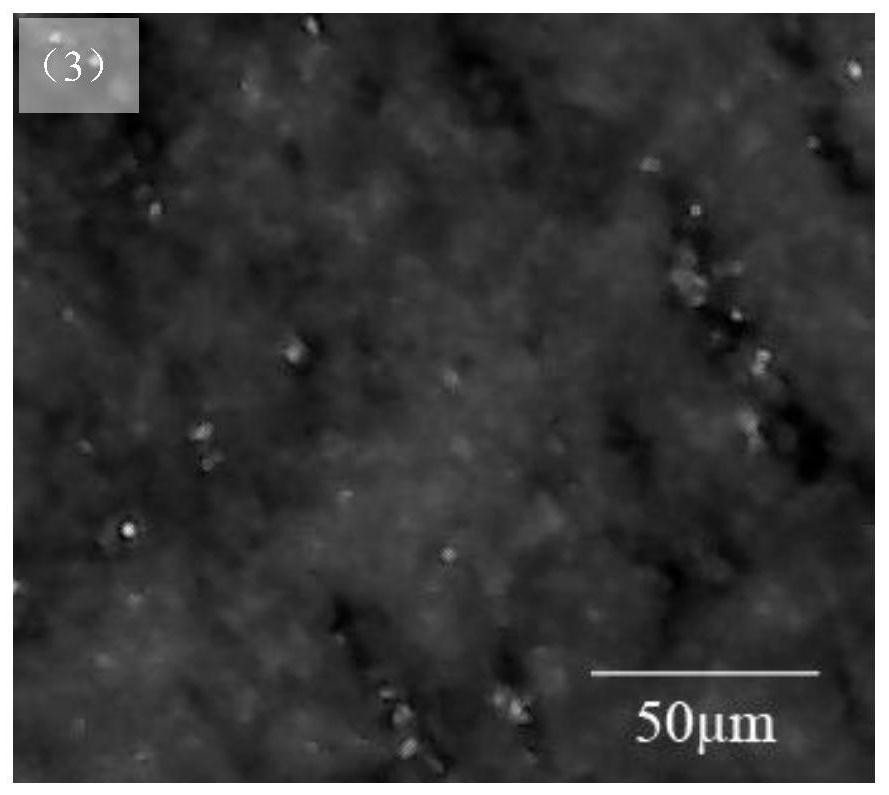

[0028] Using 3,3-diamino-N-methyldipropylamine, and poly(propylene glycol) bis(2-aminopropyl ether) as the diamine monomer, terephthalaldehyde as the dialdehyde monomer, three (2- Aminoethyl) amine is used as a crosslinking agent. According to the molar ratio of terephthalaldehyde: diamine: crosslinking agent between 1.0: 1.0: 0.2 ~ 1.0: 0.8: 0.13, crosslink the selected diamine monomer and tris(2-aminoethyl)amine The agents are jointly dissolved in an appropriate amount of a suitable solvent, and the terephthalaldehyde is additionally dissolved in an appropriate amount of the same solvent. Then mix the two solutions, and when the reaction reaches the corresponding gel point at room temperature, add carbonyl iron powder with an average particle size of 4-8 microns. The volume fraction of the carbonyl iron powder is 10%-40%. Stir wh...

example 1

[0030] Example 1. Preparation of magnetorheological elastomer compounded with carbonyl iron powder and poly(propylene glycol) bis(2-p-anilinopropyl ether) with a degree of cross-linking of 4.3%.

[0031] 1.51 g of poly(propylene glycol) bis(2-aminopropyl ether) and 0.09 g of tris(2-aminoethyl)amine were dissolved in 20 ml of methanol to form solution A. Then 1.0 g of terephthalaldehyde was dissolved in 30 ml of methanol to form solution B. After adding solution A to B and mixing, place it at room temperature for 2 hours to seal the reaction, and add 30% volume fraction of carbonyl iron powder under stirring conditions to make it uniformly dispersed in the polymerization reaction system. The temperature was raised to 40°C, the system was opened and reacted for 6 hours, and then the temperature was raised to 85°C for reaction, and the solvent was completely dried and reacted for 12 hours. Finally, it was moved to a vacuum drying oven and reacted at 50°C and 85°C for 12 hours each....

example 2

[0032] Example 2. Preparation of magnetorheological elastomer composited with carbonyl iron powder and 1.1% cross-linking poly(propylene glycol) bis(2-p-anilinopropyl ether).

[0033] Dissolve 1.67 g of poly(propylene glycol) bis(2-aminopropyl ether) and 0.02 g of tris(2-aminoethyl)amine in 20 ml of N,N-dimethylformamide to form solution C. Then 1.0 g of terephthalaldehyde was dissolved in 30 ml of N,N-dimethylformamide to form solution D. After adding solution C to D and mixing, place it at room temperature for sealing reaction for 4 hours, add 40% volume fraction of carbonyl iron powder under stirring conditions to make it uniformly dispersed in the polymerization reaction system. The temperature was raised to 60°C and the system was left open for reaction for 8 hours, and then the temperature was raised to 85°C for reaction, and the solvent was completely dried and reacted for 12 hours. Finally, it was moved to a vacuum drying oven and reacted at 50°C and 85°C for 12 hours ea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com