Preparation method of SERS substrate of Ti/TiOx/Ag hybrid composite material

A composite material and substrate technology, which is used in analytical materials, material excitation analysis, metal material coating processes, etc., can solve the problems of cumbersome substrate solutions, low detection sensitivity, and low detection sensitivity of SERS substrates.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] A preparation method of a SERS substrate of a Ti / TiOx / Ag hybrid composite material, comprising the following steps:

[0031] Step 1: Weigh the NaOH solid in a beaker, and configure an aqueous NaOH solution with a concentration of 0.5mol / L-5mol / L;

[0032] Step 2: Place the cleaned and dried titanium foil with a size of 0.5cm*0.5cm*0.1mm in a Teflon-lined stainless steel autoclave pre-filled with a volume of 30mL NaOH aqueous solution;

[0033] Step 3: Place the Teflon-lined stainless steel autoclave in step 2 in a blast drying oven for hydrothermal synthesis reaction. The temperature of the hydrothermal synthesis reaction is set at 200°C for 6 hours to obtain Ti / TiOx nano membrane;

[0034] Step 4: Take out the Ti / TiOx nano-membrane and immerse it in 30mL, 0.1mol / L HNO 3 Acid-base neutralization reaction in the solution for 2 hours;

[0035] Step 5: Repeat step 4 1-2 times until the acid-base neutralization reaction is completed, clean the Ti / TiOx nano-film with deio...

Embodiment 1

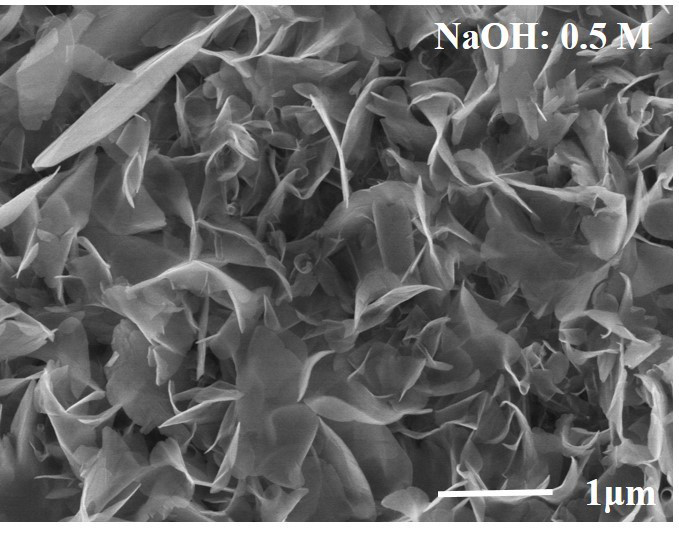

[0042] Weigh the NaOH solid powder in a beaker, and configure a NaOH aqueous solution with a concentration of 0.5mol / L; place the cleaned and dried titanium foil with a size of 0.5cm*0.5cm*0.1mm in the pre-filled NaOH with a volume of 30mL A Teflon-lined stainless steel autoclave for aqueous solution; place the Teflon-lined stainless steel autoclave in a blast drying oven, the reaction time is 6 hours, and the reaction temperature is 200 ° C; the Ti / TiOx nano-film obtained by the reaction is immersed in to a volume of 30mL and a concentration of 0.1mol / L of HNO 3 In the solution for 2 hours, and repeat 1-2 times until the acid-base neutralization reaction is completed. Then it was washed with deionized water and dried in a vacuum oven at a drying temperature of 70° C. and a drying time of 20 minutes to obtain a neutral Ti / TiOx nano film.

[0043] figure 1 It is the SEM image of the Ti / TiOx nano-film under the condition of NaOH concentration 0.5mol / L, from which the structure...

Embodiment 2

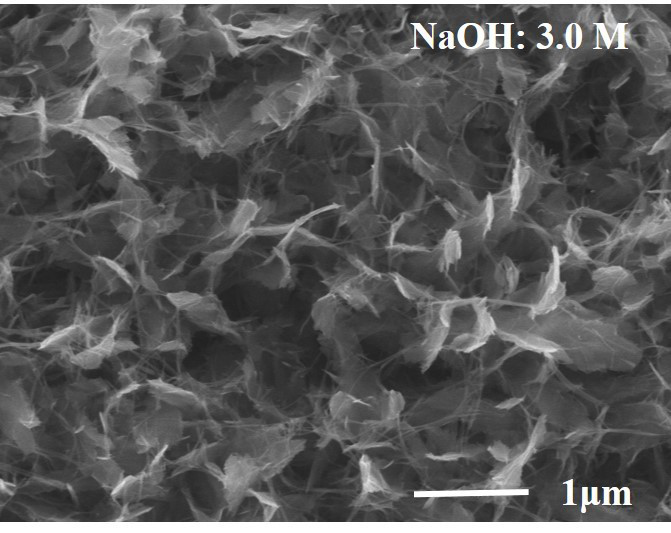

[0045] Weigh the NaOH solid powder in a beaker, and configure a NaOH aqueous solution with a concentration of 3mol / L; place the cleaned and dried titanium foil with a size of 0.5cm*0.5cm*0.1mm in a pre-filled NaOH aqueous solution with a volume of 30mL The Teflon-lined stainless steel high-pressure reactor; the Teflon-lined stainless steel high-pressure reactor was placed in a blast drying oven, the reaction time was 6 hours, and the reaction temperature was 200 ° C; the Ti / TiOx nano-film obtained by the reaction was immersed in HNO with a volume of 30mL and a concentration of 0.1mol / L 3 In the solution for 2 hours, and repeat 1-2 times until the acid-base neutralization reaction is completed. Then it was washed with deionized water and dried in a vacuum oven at a drying temperature of 70° C. and a drying time of 20 minutes to obtain a neutral Ti / TiOx nano film.

[0046] figure 2 It is the SEM image of the Ti / TiOx nano-film under the condition of NaOH concentration 3mol / L, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com