Sponge carrier catalyst for catalytic hydrolysis hydrogen production and preparation method and application thereof

A catalytic hydrolysis and catalyst technology, applied in the direction of catalyst activation/preparation, organic compound/hydride/coordination complex catalyst, physical/chemical process catalyst, etc., can solve the problem of inability to realize catalyst recovery and multiple use, weak physical adsorption Effect, transition metal shedding and other problems, to achieve the effect of easy recycling and multiple use, increase hydrogen storage density, and enhance force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

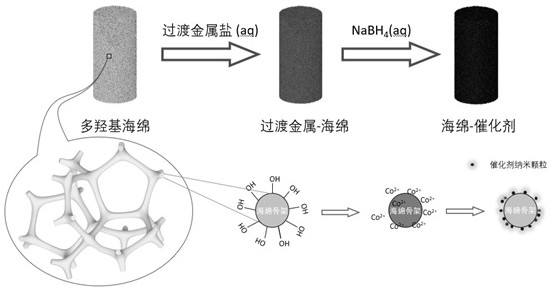

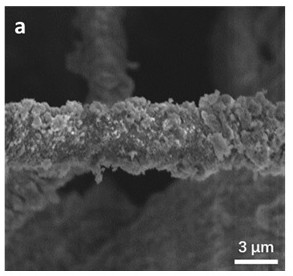

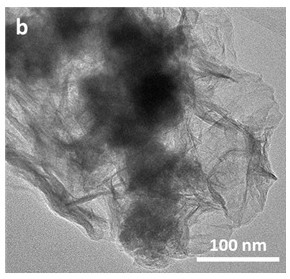

[0051] The preparation process of the sponge carrier catalyst is as follows: figure 1 shown. Using polyvinyl formal (PVF) sponge as the carrier, the apparent density is 0.12g cm -3 , cut into a cylinder of Φ20mm*h50mm. The surface of PVF sponge has oxygen-containing groups, which can directly adsorb transition metal ions. Preparation of CoCl with a mass fraction of 10% 2 Put 20mL of aqueous solution into the PVF sponge, squeeze it repeatedly for 3 to 5 times, and fully soak it so that the PVF sponge can fully absorb CoCl 2 aqueous solution. will absorb full CoCl 2 The PVF sponge in aqueous solution was placed in an oven at 60 °C and dried for 24 hours. Put the dried PVF sponge into 50mL NaBH with a mass fraction of 5% 4 Fully react in aqueous solution, wash with water repeatedly, and squeeze 2 to 3 times to obtain a PVF sponge-supported catalyst loaded with Co-B, wherein the molar ratio of Co:B is 2:1, and the mass of Co-B is about that of PVF sponge. 10%, figure 2 S...

Embodiment 2

[0055] Using melamine (MF) sponge as the carrier, the apparent density is 0.008 g cm -3 , the surface of MF sponge has no functional groups that coordinate with transition metal ions, and its interaction force with transition metal ions is enhanced by plasma surface modification. Cut the melamine sponge into small pieces with a side length of 0.5 cm, and place it in a quartz reactor with an inner diameter of 5 cm for plasma modification. The reaction conditions are: at room temperature, the reactor pressure is 100 Pa, and the atmosphere is air containing 30% water vapor. , with a total gas flow rate of 200mL / min, 100W radio frequency glow discharge plasma treatment for 20min, to introduce oxygen-containing functional groups to the surface of MF sponge fibers.

[0056] A total of 300cm of MF sponge after plasma treatment 3 With 250mL Ni(NO 3 ) 2 The solution is fully mixed, and repeatedly squeezed 3 to 5 times to make the sponge fully absorb Ni(NO 3 ) 2 solution, keep the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com