Method for repairing Glare laminate by bonding with modified adhesive

A technology of adhesive and modifier, applied in the direction of surface pretreatment bonding method, adhesive, bonding method, etc., can solve the problems of limited repair performance, large drilling stress concentration, etc., to improve adhesion and cohesion, increase strength, increase the effect of adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

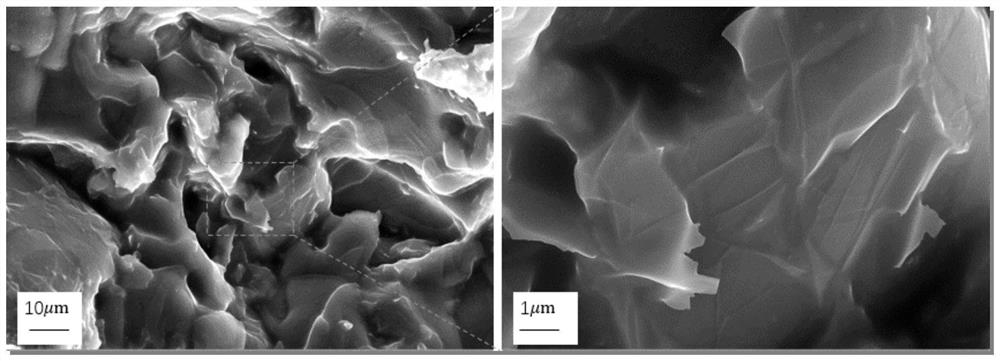

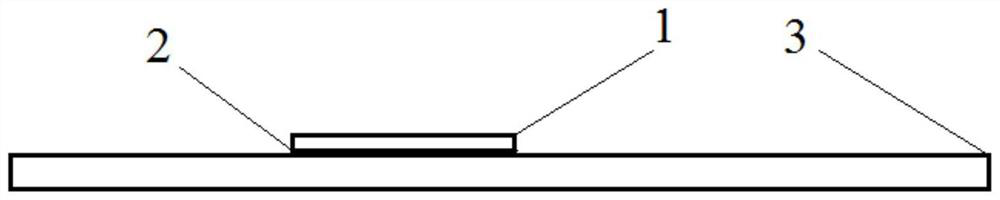

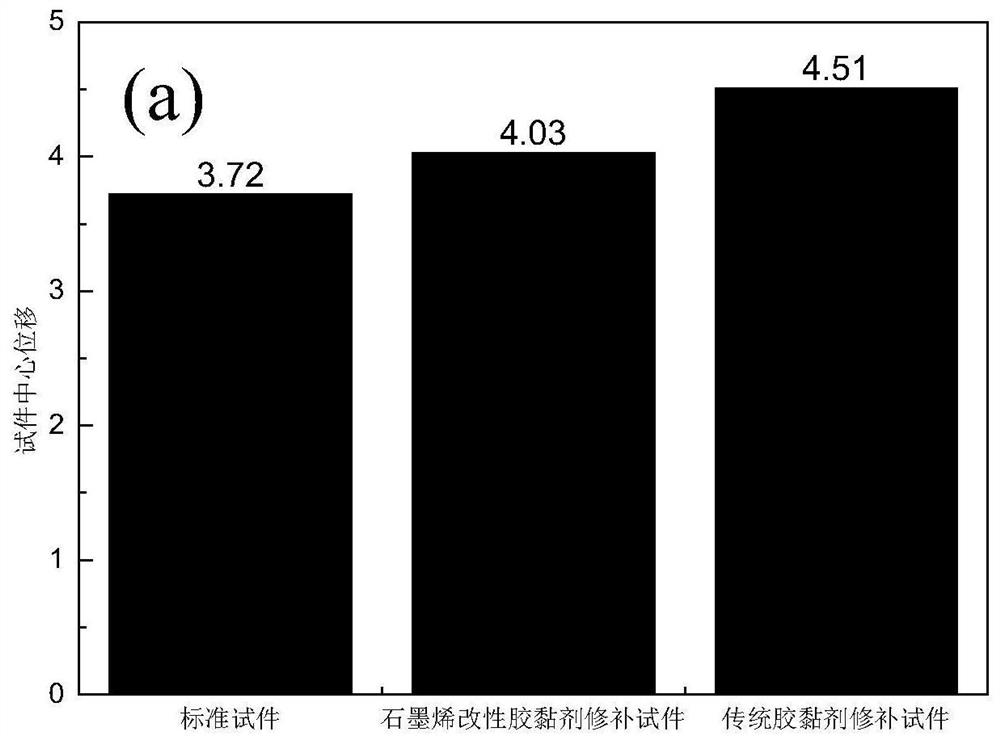

[0033] A kind of graphene-modified adhesive is to the adhesive bonding repairing method that contains impact damage Glare laminate, and implementation steps are as follows:

[0034] In order to implement this embodiment, a complete Glare laminate is prepared first, and then a damaged Clare laminate is simulated to manufacture a damaged Glare laminate. The specific operation method is as follows: firstly, the surface treatment of the aluminum plate is carried out by anodizing method, and then the glass fiber pre-invasion material is laid by spraying adhesive, cured by hot pressing, and processed into the required shape. After that, ultrasonic scanning non-destructive testing should be carried out on the processed test pieces to detect whether there are defects that are not visible to the naked eye during the preparation and processing. The impact damage of Glare laminates was simulated by drop weight impact test. The simulated damage is at a repairable damage level; the area o...

Embodiment 2

[0045] A kind of carbon nanotube modified adhesive is to the adhesive repair method of the Glare laminate containing fatigue damage, and the implementation steps are as follows:

[0046] In order to implement this embodiment, a complete Glare laminate is prepared first, and then a damaged Clare laminate is simulated to manufacture a damaged Glare laminate. The specific operation method is as follows: firstly, the surface treatment of the aluminum plate is carried out by anodizing method, and then the glass fiber pre-invasion material is laid by spraying adhesive, cured by hot pressing, and processed into the required shape. After that, ultrasonic scanning non-destructive testing should be carried out on the processed test pieces to detect whether there are defects that are not visible to the naked eye during the preparation and processing. Through fatigue crack simulation, the damage of Glare laminates under cyclic loading is simulated, and the simulated damage is at the level...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com