Electrostatic chuck and preparation method thereof

An electrostatic chuck and electrostatic technology, which is applied in the manufacture of circuits, electrical components, semiconductor/solid-state devices, etc., can solve the problems of insufficient temperature conduction rate, ineffective desorption of wafers, poor thermal conductivity, etc., to achieve high heating efficiency and avoid material Dimensional difference and internal tissue deterioration, high temperature uniformity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

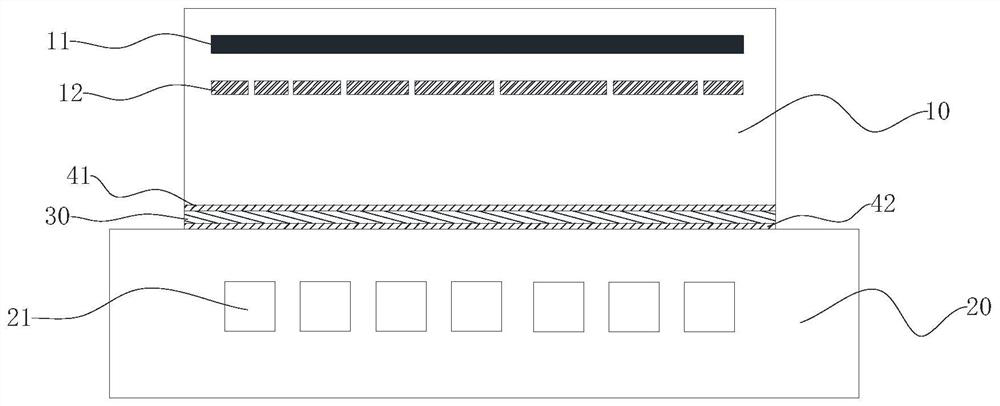

[0040] Please also refer to image 3 , Figure 6 , the preparation method of the electrostatic chuck of the present invention specifically comprises the following steps:

[0041] 1) Ceramic slurry preparation

[0042] Use 0.1-1 micron alumina ceramic particles as raw material, purity ≥ 99.9%, take alumina ceramic particles as the measurement base, add CaO or CaF below 5wt.% 2 or MgF 2 As a sintering aid, dispersant below 1wt.%, binder below 5wt.%, plasticizer below 3wt.%, and the rest are solvents. The solid phase content is 45%-60%. Ball milling for 24h, the into a uniformly dispersed ceramic slurry. The solvent can be selected from toluene, xylene, ethanol, isopropanol, ethylene glycol, etc., the dispersant can be selected from polyacrylic acid, fatty acid, fish oil, etc., the binder can be selected from polyethylene, ethyl cellulose, PVB, etc., plasticizer PEG, PVA, CMC, and PVAC can be used alone or in combination, and there is no special limitation.

[0043] 2) Form...

Embodiment 1

[0059] 1) Ceramic blank preparation

[0060] Use 1μm spherical alumina ceramic particles as raw material, purity ≥ 99.9%, take the weight of the ceramic particles as the measurement base, add less than 0.5wt.% CaO, 3wt.% MgF 2 As a sintering aid, ethanol is used as a solvent, 0.8wt.% polyacrylic acid is added as a dispersant, 2.5wt.% PVB is used as a binder and 3wt.% PEG is used as a plasticizer, and the solid phase content is adjusted to 55%. Ball milled for 24 hours to make evenly dispersed ceramic slurry, which was tape-cast to form a ceramic blank, and the ceramic blank was drilled.

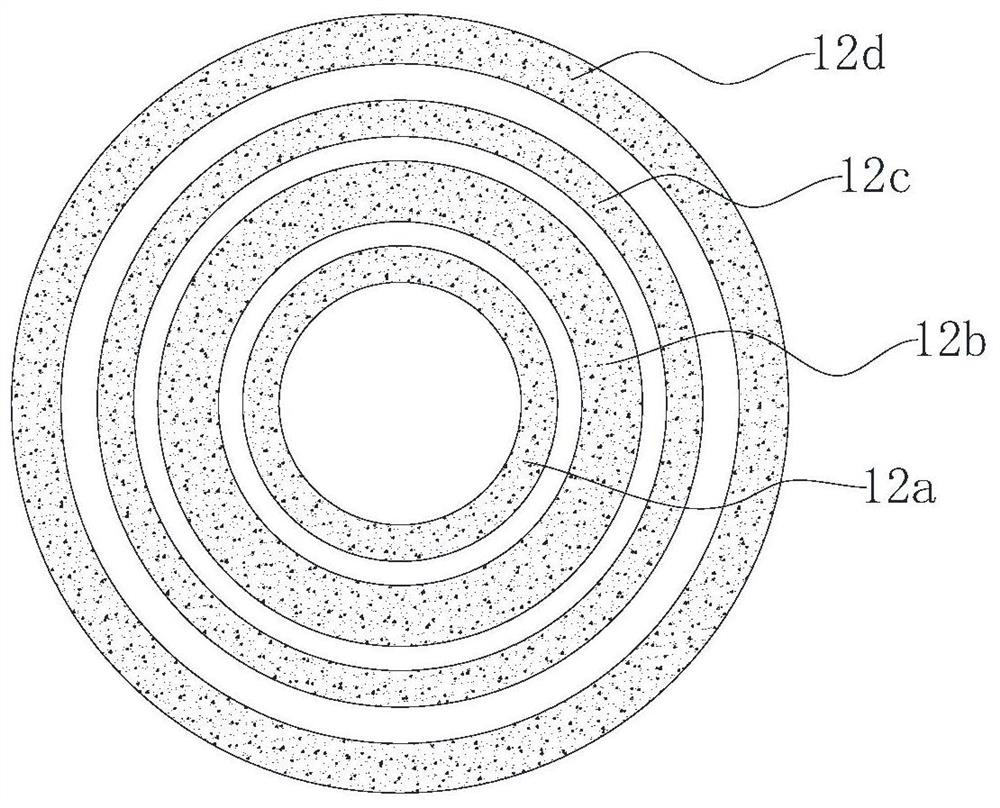

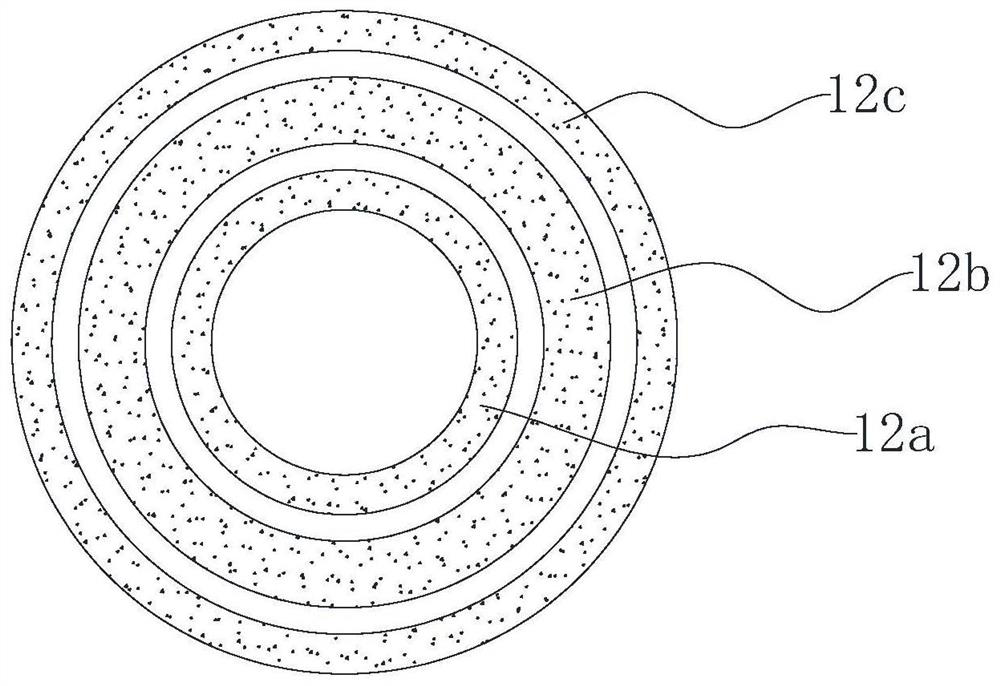

[0061] 2) Electrode fabrication

[0062] Add W powder and 5wt.% Ti powder to polymer to make conductive paste, print electrostatic electrodes on the upper surface of a ceramic blank, and print heating electrodes on the lower surface of the same ceramic blank. The electrostatic electrode is grid-shaped, the thickness of the electrode is 15 μm, and the shape of the electrode is circular. The...

Embodiment 2

[0072] 1) Ceramic blank preparation

[0073] Use 0.5μm spherical alumina ceramic particles as raw material, purity ≥ 99.9%, take the weight of the ceramic particles as the measurement base, add less than 1wt.% CaO, 2wt.% MgF 2 As a sintering aid, use absolute ethanol as a solvent, add 0.8wt.% polyacrylic acid as a dispersant, 2.5wt.% PVB as a binder and 3wt.% PEG as a plasticizer, and adjust the solid phase content to 60 %, ball milled for 24 hours to make a uniformly dispersed ceramic slurry, which was taped to form a ceramic blank, and the ceramic blank was drilled.

[0074] 2) Electrode fabrication

[0075] Add W powder and 10wt.% Ti powder to polymer to make conductive paste, print electrostatic electrodes on the upper surface of a ceramic blank, and print heating electrodes on the lower surface of the same ceramic blank. The electrostatic electrode is grid-shaped, the thickness of the electrode is 10 μm, and the shape of the electrode is circular. The heating electrode...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com