Nickel oxide composite film and preparation method thereof and led

A composite film, nickel oxide technology, applied in semiconductor/solid-state device manufacturing, organic semiconductor devices, coatings, etc., can solve problems such as unsatisfactory hole transport effect and low work function, and avoid complex and time-consuming preparation processes. The effect of improving work function and good application prospect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] On the one hand, the embodiment of the present invention provides a preparation method of a nickel oxide composite film, and the preparation method includes the following steps:

[0031] S01: Provide initial nickel oxide film;

[0032] S02: depositing alkyl sulfate on the surface of the initial nickel oxide film, and then performing oxygen plasma treatment to obtain the nickel oxide composite film.

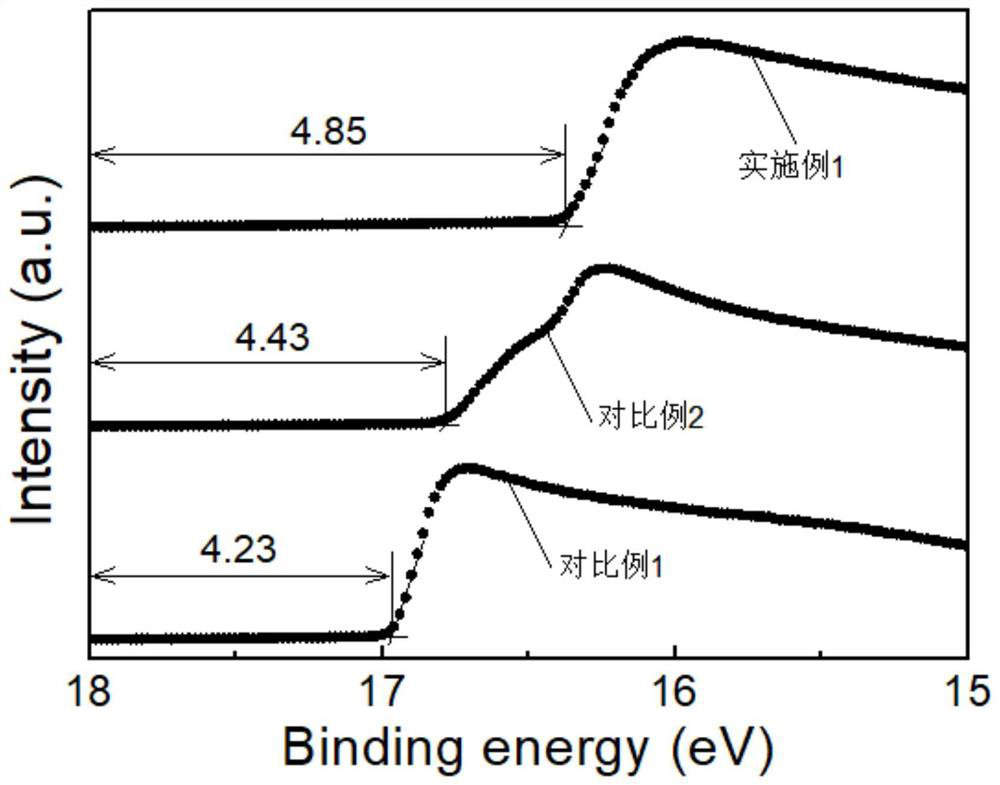

[0033] In the method for preparing the nickel oxide composite film provided by the embodiment of the present invention, an alkyl sulfate is first deposited on the surface of the initial nickel oxide film, and then an oxygen plasma treatment is performed to obtain a modified nickel oxide composite film. The preparation method has simple process and good repeatability, avoids the complex and time-consuming problem of traditional metal cation doping preparation process, and the preparation method can significantly improve the work function of the nickel oxide composite film, a...

Embodiment 1

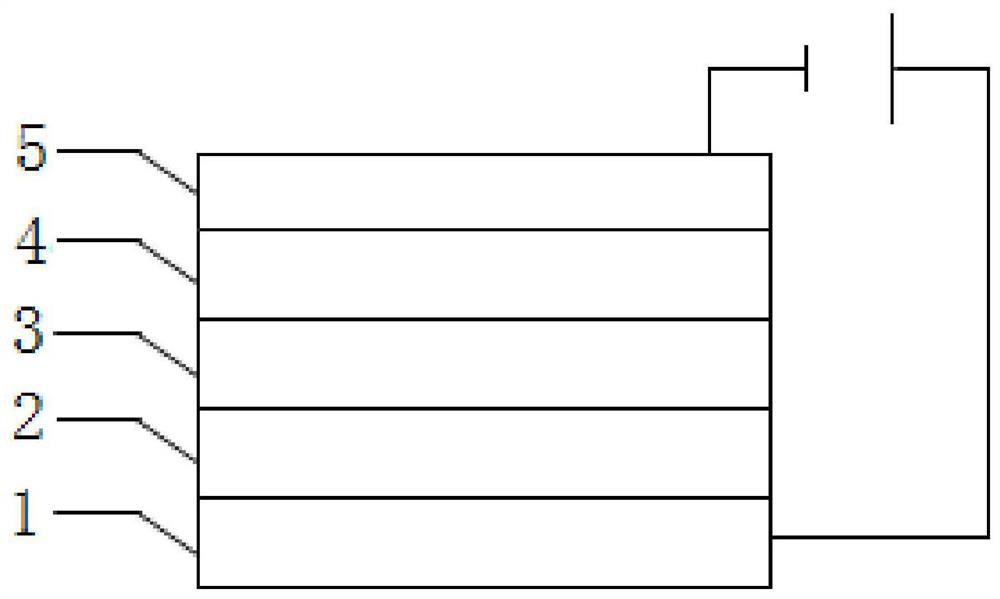

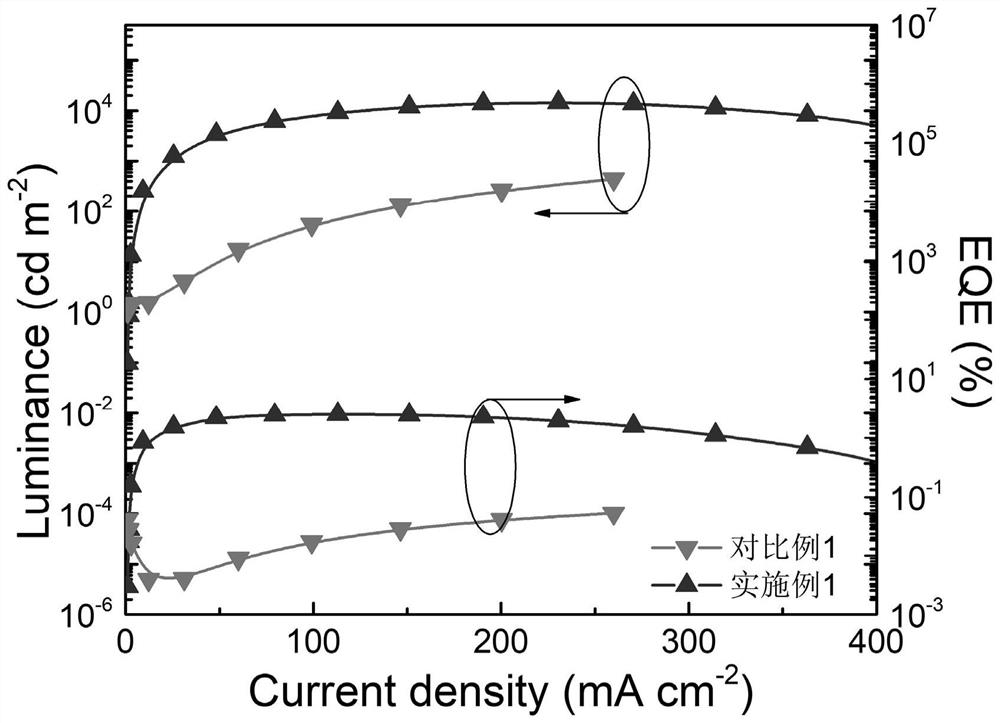

[0055] A perovskite light-emitting diode whose structure is as follows figure 1 As shown, it includes an anode 1 , a hole transport layer 2 , a perovskite light-emitting layer 3 , an electron transport layer 4 and a cathode 5 in order from bottom to top. The material of anode 1 is ITO, the material of hole transport layer 2 is nickel oxide composite film, the material of electron transport layer 4 is TPBI, and the material of cathode 5 is LiF / Al.

[0056] The preparation steps of the above hole transport layer 2 include:

[0057] Dissolve 1 mmol of nickel acetate tetrahydrate and 60 μL of ethanolamine in 10 ml of ethanol solution, and stir at 60 °C for 4 hours to obtain a nickel oxide precursor solution; filter the nickel oxide precursor with a polytetrafluoroethylene filter, in a 1cm × 1cm The anode ITO substrate was spin-coated and loaded with 50 μL of the above-mentioned nickel oxide precursor solution (prepared by solution spin-coating under the conditions of 4000 rpm and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electron work function | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com