Lithium battery thick pole piece rolling method, pole piece rolling device and lithium battery

A lithium battery and roll pressing technology, which is applied in electrode rolling/calendering, electrode collector coating, electrode manufacturing, etc., can solve the problem of difficult to achieve large-scale processing and mass production, and the difficulty of high-pressure compaction for thick electrodes, improving Without problems such as energy density, it can achieve the effect of increasing dependence, realizing large-scale processing and mass production, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

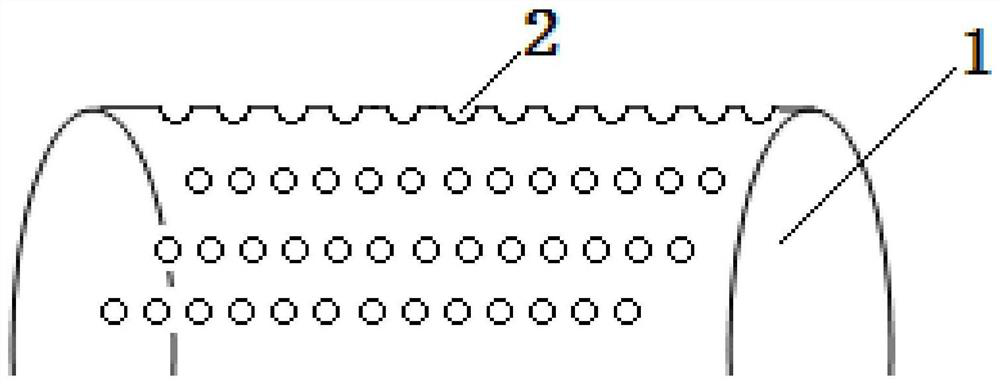

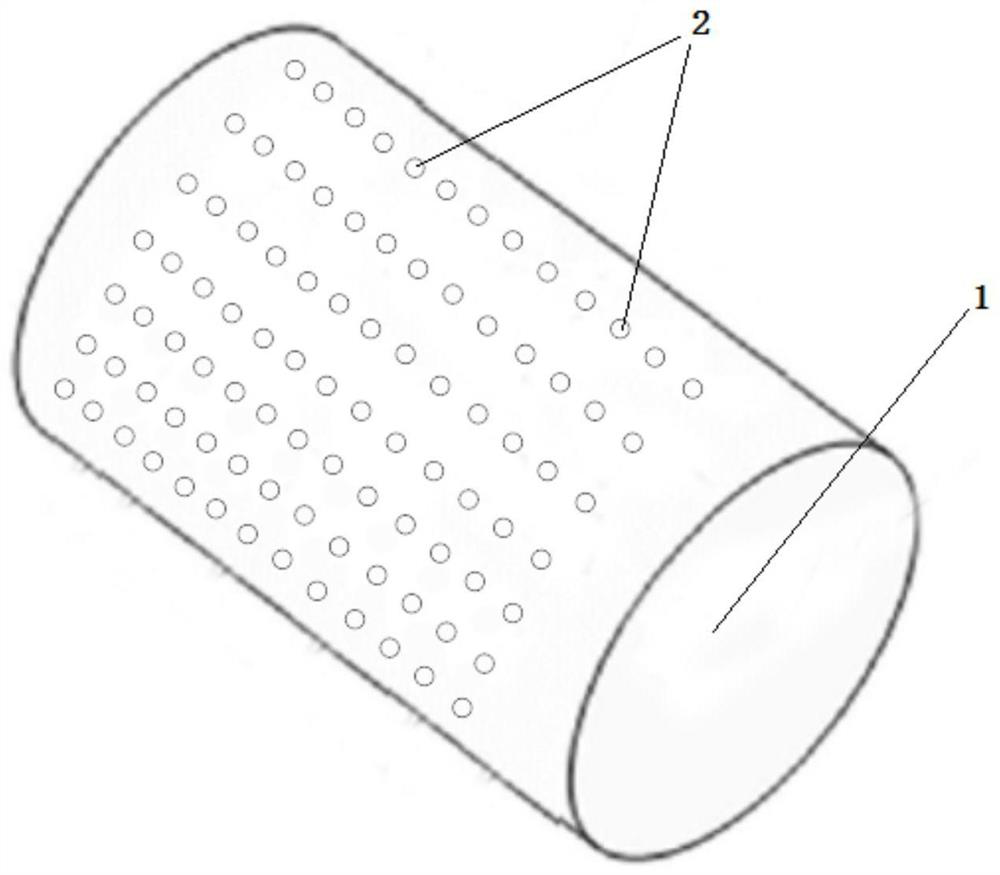

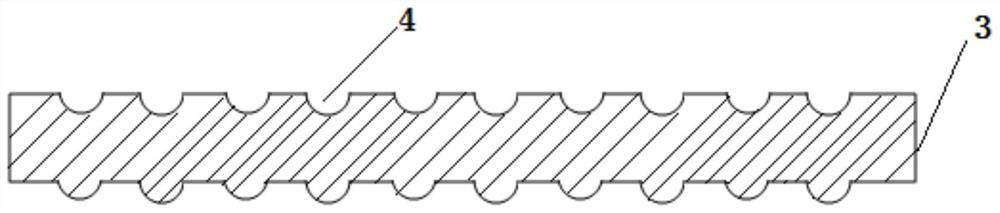

[0021] Preparation of thick positive electrode sheet: Dry mix 96.8% of the positive electrode active material lithium iron phosphate, 0.5% of the conductive agent SP, 0.85% of the emulsion polymerization binder PVDF and 0.85% of the suspension polymerization binder PVDF, and then add dispersing 0.5% carbon nanotube and graphene mixed conductive agent, 1.0% carbon nanotube and graphene mixed conductive agent, mixed and stirred evenly, wherein the diameter of carbon nanotube is 5nm, and the viscosity is 5000-8000mPa·s, and the positive electrode slurry is prepared, and the positive electrode slurry is coated on On the carbon aluminum foil, after drying, a positive electrode sheet with a thickness of 300 μm is obtained, and the electrode sheet rolling device of the present invention is used for secondary rolling, wherein the first rolling compaction density is 2.0g / cc, and the second rolling compaction The density is 2.55g / cc, and then die-cut to obtain a thick positive electrode ...

Embodiment 2

[0025] Preparation of thick positive electrode sheet: Dry mix 96.8% of the positive electrode active material lithium iron phosphate, 0.6% of conductive agent SP, 0.8% of emulsion polymerization binder PVDF and 0.8% of suspension polymerization binder PVDF, and then add dispersing 0.5% carbon nanotube and graphene mixed conductive agent, 1.0% carbon nanotube and graphene mixed conductive agent, mixed and stirred evenly, wherein the diameter of carbon nanotube is 5nm, and the viscosity is 5000-8000mPa·s, and the positive electrode slurry is prepared, and the positive electrode slurry is coated on On the carbon aluminum foil, after drying, a positive electrode sheet with a thickness of 300 μm is obtained, and the electrode sheet rolling device of the present invention is used for secondary rolling, wherein the first rolling compaction density is 2.1g / cc, and the second rolling compaction The density is 2.57g / cc, and then die-cut to obtain a thick positive electrode sheet;

[002...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Compaction density | aaaaa | aaaaa |

| Compaction density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com