Simple and efficient flue-cured tobacco non-film-uncovering compartment-loading cultivation method

A cultivation method and flue-cured tobacco technology, applied in the field of flue-cured tobacco planting and crop cultivation, can solve the problems of low planting efficiency, low yield of tobacco leaves, high planting cost, etc., and achieve the goal of promoting sustainable development, improving utilization rate, and balancing inorganic nutrients Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

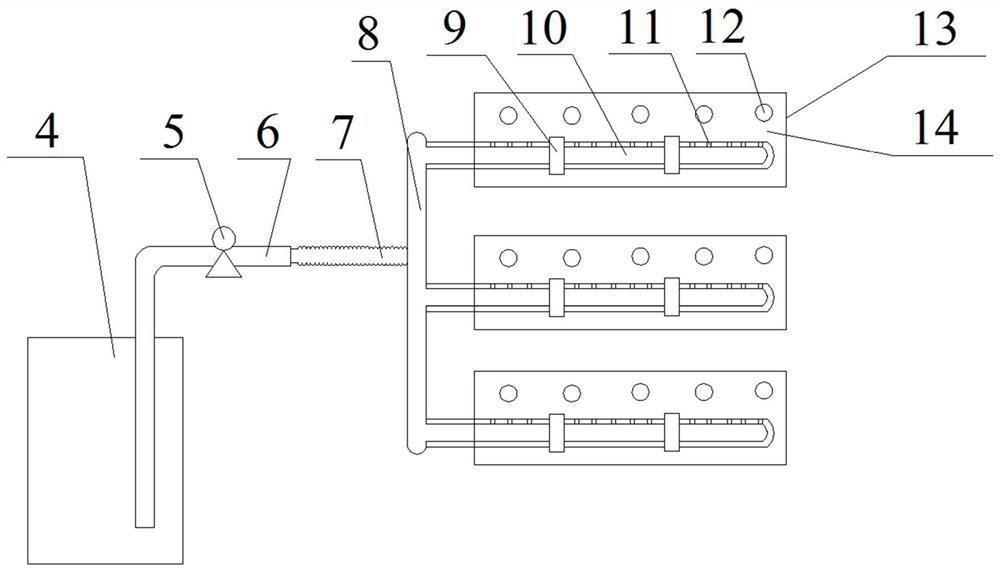

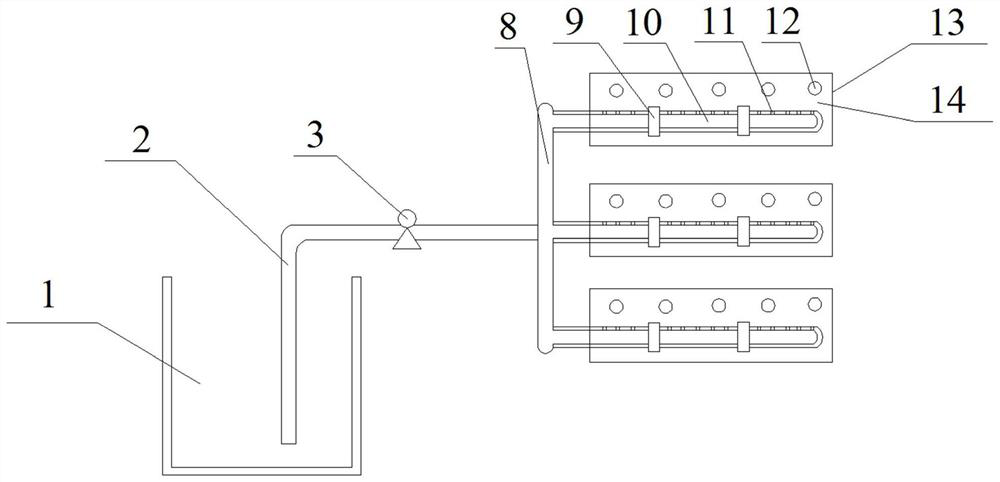

[0057] Such as figure 1 As shown, a light, simple and high-efficiency cultivation method of flue-cured tobacco without film upper chamber, comprising the following steps:

[0058] Step 1, Ridging 13 in the tobacco planting field and forming multiple ridges 13;

[0059] Step 2. Fertilize on each ridge 13. Apply granular organic fertilizer and granular organic-inorganic compound fertilizer at one time and cover with soil. Fertilization includes circle or strip fertilization. Circle fertilization is circular fertilization at a distance of 5-7cm from the tobacco seedlings. , strip fertilization is to open a 5-8cm wide and 10-15cm deep groove on one side or both sides of the tobacco seedlings;

[0060] Step 3, install the sprinkler system, the sprinkler system includes a ridge 13 and a sprinkler system, the sprinkler system includes a water supply mechanism on one side of the ridge 13, communicates with the water supply mechanism and is located in the ridge 13 upper sprinkler pip...

Embodiment 2

[0065] On the basis of Example 1, in step 2, 60-80 kg of granular organic fertilizer was applied per mu, and 70-90 kg of granular organic-inorganic compound fertilizer was applied per mu.

Embodiment 3

[0067] On the basis of embodiment 2, the preparation method of granular organic fertilizer comprises the steps:

[0068] a. Mechanically mix the raw materials uniformly, and adjust the water content to 55-65%. The raw materials include 40-50 parts of fungus residue, 20-30 parts of dried oil, 20-30 parts of dried cow dung, and straw 10-20 parts of powder, 1-2 parts of urea, 0.2-0.5 parts of fermentation bacteria;

[0069] b. Ferment in a trough-type fermenter with ventilation and air extraction devices for 10-20 days in a closed manner, and use a crawler-type material turning machine to automatically turn the material 3-5 times during the fermentation;

[0070] c. The fermented material is dried, cooled, crushed and sieved to make an organic material with a fineness of 30-60 mesh;

[0071]d, add monoammonium phosphate, potassium sulfate, amino acid, humic acid, magnesium sulfate, zinc sulfate, boric acid, bentonite granulation, granulation raw materials, by weight, organic mat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com