Fermented feed for laying hens as well as preparation method and application thereof

A technology for fermented feed and laying hens, which is applied in the field of fermented feed for laying hens and its preparation, can solve the problems of complex components of corn steep liquor and difficult application in the feed industry, achieve obvious economic and ecological benefits, eliminate adverse effects, and reduce equipment investment little effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0070] The embodiment of the invention provides a fermented feed for laying hens and a preparation method thereof.

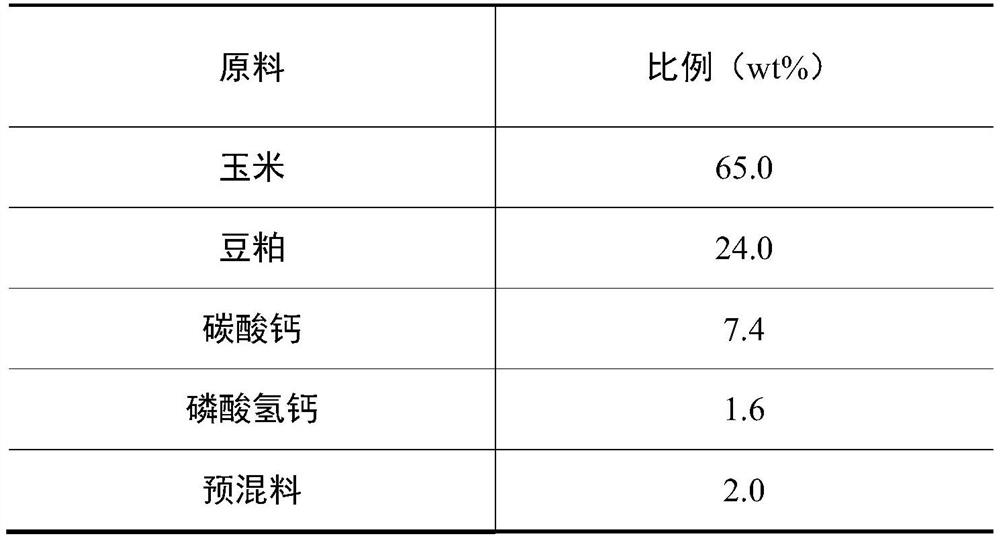

[0071] 1. Raw materials

[0072] Corn syrup: 1500kg;

[0073] Corn husk: 1000kg;

[0074] Hydrogen peroxide: 20kg, the effective content is 28.0%;

[0075] Ammonia water: 100kg, the effective content is 20.0%;

[0076] Wheat bran: 250kg;

[0077] Brad's yeast culture medium: 40kg;

[0078] Bacillus subtilis culture solution: 40kg;

[0079] Streptococcus salivarius subspecies thermophilic culture medium: 50kg.

[0080] 2. Preparation method

[0081] Take 1500kg of corn steep liquor, first add 20kg of hydrogen peroxide and mix well to oxidize the sulfite in it, then add 100kg of ammonia water to adjust its pH value to about 6.2; at the same time, treat 250kg of wheat bran with a granulation conditioner for 4 minutes, steam pressure is 0.2MPa.

[0082] The treated corn steep liquor and wheat bran are evenly mixed with 1000kg of corn bran, then inoculated w...

Embodiment 2

[0093] The embodiment of the invention provides a fermented feed for laying hens and a preparation method thereof.

[0094] 1. Raw materials

[0095] Corn syrup: 1000kg;

[0096] Corn husk: 1000kg;

[0097] Hydrogen peroxide: 12kg, the effective content is 28.0%;

[0098] Ammonia water: 65kg, the effective content is 20.0%;

[0099] Wheat bran: 250kg;

[0100] Brad's yeast culture medium: 40kg;

[0101] Bacillus subtilis culture solution: 40kg;

[0102] Streptococcus salivarius subspecies thermophilic culture medium: 40kg.

[0103] 2. Preparation method

[0104] Take 1000kg of corn steep liquor, first add 12kg of hydrogen peroxide and mix well to oxidize the sulfite in it, then add 65kg of ammonia water to adjust its pH value to about 6.2; at the same time, treat 250kg of wheat bran with a granulation conditioner for 4 minutes, steam pressure is 0.2MPa.

[0105] The treated corn steep liquor and wheat bran are evenly mixed with 1000kg of corn bran, then inoculated wit...

Embodiment 3

[0113] The embodiment of the invention provides a fermented feed for laying hens and a preparation method thereof.

[0114] 1. Raw materials

[0115] Corn syrup: 2000kg;

[0116] Corn husk: 1000kg;

[0117] Hydrogen peroxide: 24kg, the effective content is 28.0%;

[0118] Ammonia water: 130kg, the effective content is 20.0%;

[0119] Wheat bran: 250kg;

[0120] Brad's yeast culture medium: 40kg;

[0121] Bacillus subtilis culture solution: 40kg;

[0122] Streptococcus salivarius subspecies thermophilic culture medium: 30kg.

[0123] 2. Preparation method

[0124] Take 2000kg of corn steep liquor, first add 24kg of hydrogen peroxide and mix well to oxidize the sulfite in it, then add 130kg of ammonia water to adjust its pH value to about 6.2; at the same time, treat 250kg of wheat bran with a granulation conditioner for 4 minutes, steam pressure is 0.2MPa.

[0125] The treated corn steep liquor and wheat bran are evenly mixed with 1000kg of corn bran, then inoculated w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com