Preparation method and application of guanidine salt ionic liquid modified magnetic solid-phase extraction adsorbent

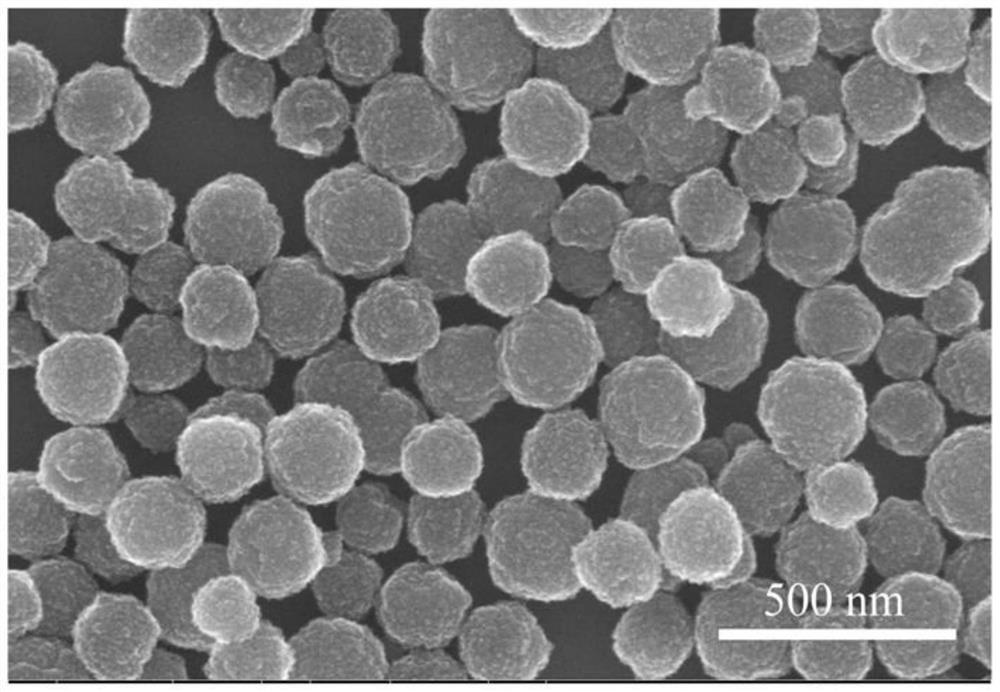

An ionic liquid and adsorbent technology, which is applied in the field of magnetic solid phase extraction adsorbents modified by guanidine salt ionic liquids, can solve the problems of aggregation corrosion and insufficient extraction efficiency of nanoparticles, and achieves high dispersibility, increased hydrophilicity and extraction. Ability, particle size uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

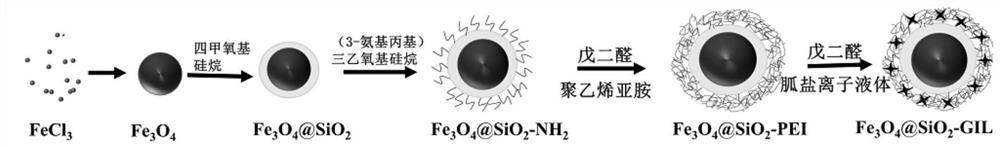

[0039] Embodiment 1: Preparation of Fe modified by guanidinium salt ionic liquid 3 o 4 @SiO 2 -GIL Magnetic Nanocomposite

[0040] Preparation process: Dissolve 1,1,3,3-tetramethylguanidine (1mL), tetrabutylammonium bromide (0.17g), p-chlorobenzylamine (9g) and potassium carbonate (2g) in methanol (50mL ) at 60°C for 40h, then cooled to room temperature and filtered. The filtrate was evaporated in vacuo to remove the solvent, and the residue was washed three times with n-hexane, ethyl acetate and triethylamine, respectively. A small amount of water was added, followed by solid NaOH to bring the aqueous solution to pH=8. Water was removed by evaporation, and the resulting liquid was extracted with a mixed solution of ethanol:tetrahydrofuran (v / v, 1:1). The solid precipitate was removed by centrifugation and the solvent was removed by rotary evaporation. After centrifugation and evaporation, the resulting product was vacuum-dried at 60 °C to obtain a light yellow viscous l...

Embodiment 2

[0043] Embodiment 2: Preparation of Fe modified by guanidinium salt ionic liquid 3 o 4 @SiO 2 -GIL Magnetic Nanocomposite

[0044] The preparation process is shown in Figure 1(a). 1,1,3,3-tetramethylguanidine (2.5mL), tetrabutylammonium bromide (0.3g), 3-chloroethylamine hydrochloride (10g ) and potassium carbonate (6 g) were dissolved in methanol (50 mL) and refluxed at 75 °C for 20 h, then cooled to room temperature and filtered. The filtrate was evaporated in vacuo to remove the solvent, and the residue was washed three times with n-hexane, ethyl acetate and triethylamine, respectively. A small amount of water was added, followed by solid NaOH to bring the aqueous solution to pH = 8.3. Water was removed by evaporation, and the resulting liquid was extracted with a mixed solution of ethanol:tetrahydrofuran (v / v, 1:1.5). The solid precipitate was removed by centrifugation and the solvent was removed by rotary evaporation. After centrifugation and evaporation, the result...

Embodiment 3

[0047] Embodiment 3: Preparation of Fe modified by guanidinium salt ionic liquid 3 o 4 @SiO 2 -GIL Magnetic Nanocomposite

[0048] The preparation process is shown in Figure 1(a). 1,1,3,3-tetramethylguanidine (3mL), tetrabutylammonium bromide (0.1g), 3-bromopropylamine hydrochloride (11g) and Potassium carbonate (4 g) was dissolved in methanol (50 mL) and refluxed at 80 °C for 36 h, then cooled to room temperature and filtered. The filtrate was evaporated in vacuo to remove the solvent, and the residue was washed three times with n-hexane, ethyl acetate and triethylamine, respectively. A small amount of water was added, followed by solid NaOH to bring the aqueous solution to pH=9. Water was removed by evaporation, and the resulting liquid was extracted with a mixed solution of ethanol:tetrahydrofuran (v / v, 1:2). The solid precipitate was removed by centrifugation and the solvent was removed by rotary evaporation. After centrifugation and evaporation, the resulting produc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Saturation magnetization value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com