Pseudo-capacitor material polypyrrole-coated Fe2O3/Mn2O3 composite material and preparation method of polypyrrole-coated Fe2O3/Mn2O3 composite material

A technology of composite materials and polypyrrole, applied in nanotechnology, circuits, negative electrodes, etc. for materials and surface science, can solve the problems of low initial Coulombic efficiency, poor rate capability, fast capacity decay, etc., and achieve good cycle stability The effect of high stability, regular shape and high controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

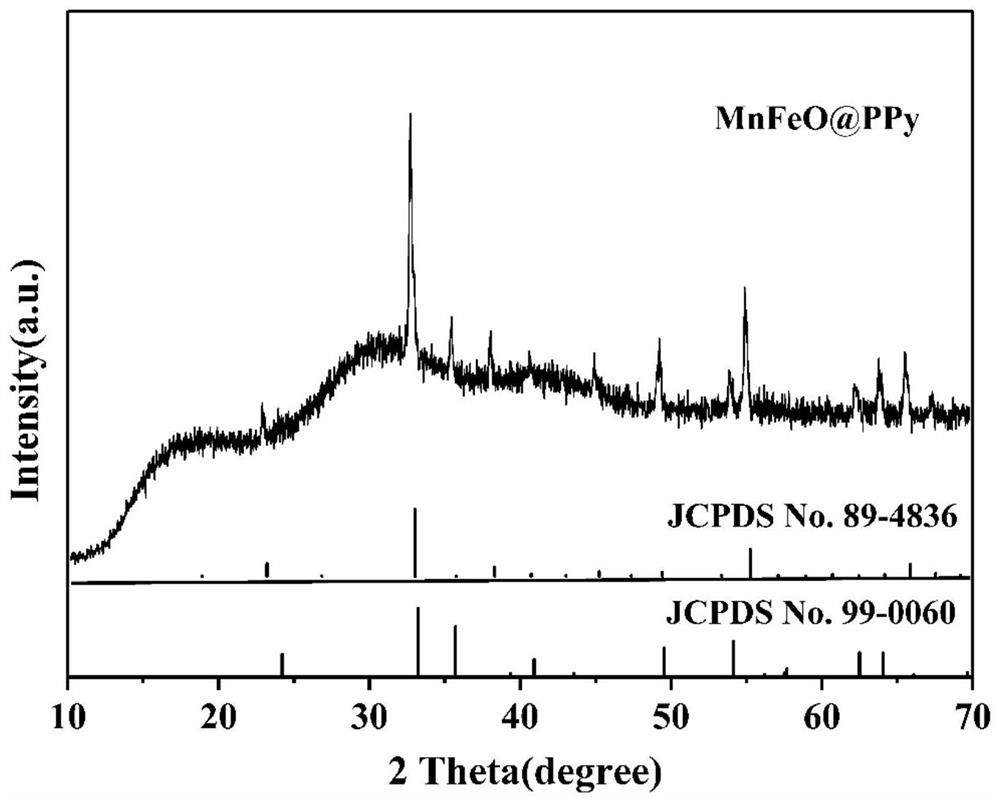

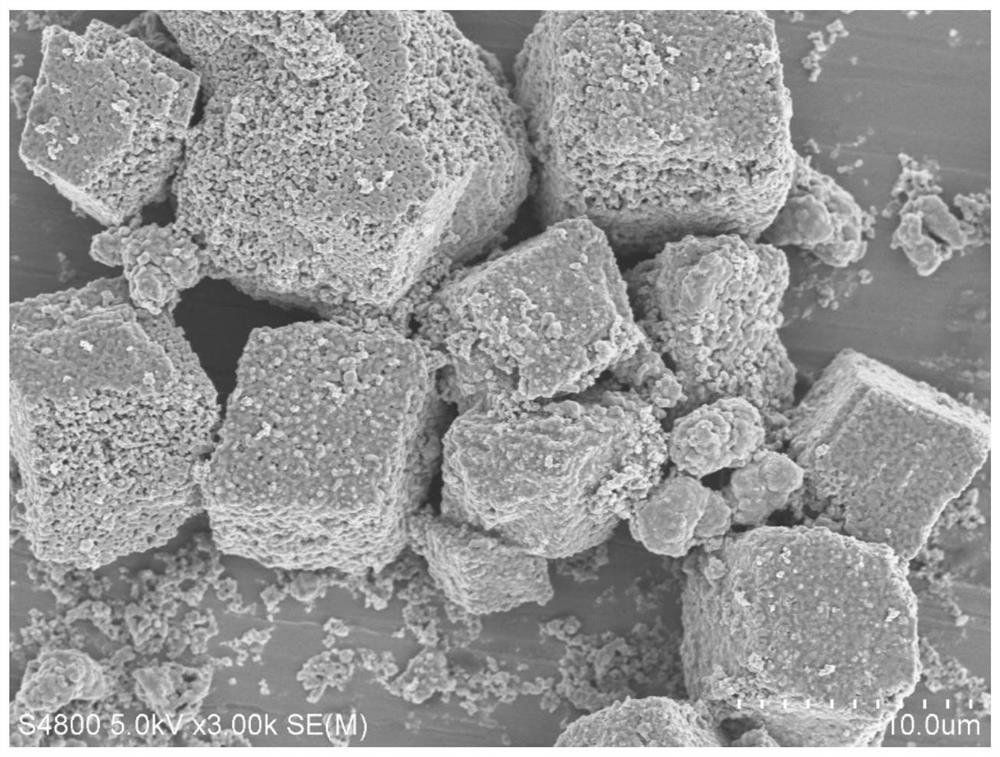

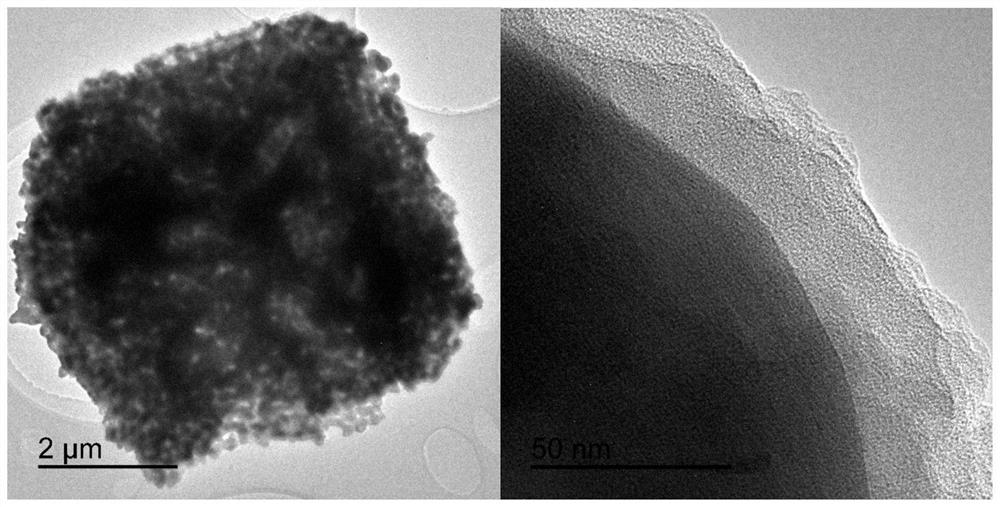

[0026] The invention provides a pseudocapacitance material polypyrrole-coated Fe 2 o 3 / Mn 2 o 3 The preparation method of composite material, comprises the following steps:

[0027] 1) Take 0.4~1.5g of MnSO 4 ·H 2 O and 0.3-1.8g of Fe(NO 3 ) 3 9H 2 O was dissolved in 30-70 mL of deionized water and stirred evenly to obtain a mixed solution, and the mixed solution was heated at a temperature of 120-180 °C for 12-24 hours to perform a hydrothermal reaction to obtain product A; that is, to control MnSO 4 ·H 2 O and Fe(NO 3 ) 3 9H 2 The molar ratio of O is: (1:1)-(5:1); preferably, the mixed solution is hydrothermally reacted in an autoclave, and the volume of the mixed solution is controlled not to exceed 70% of the volume of the autoclave.

[0028] 2) After washing and drying product A, heat at 500-1000°C for 3-8 hours for annealing treatment to obtain product B; product B is Fe 2 o 3 / Mn 2 o 3 nanoparticles;

[0029] 3) Put product B in 40-60 mL of p-toluenesu...

Embodiment 1

[0037] The preparation method comprises the following steps:

[0038] Step 1: Weigh 0.4g MnSO 4 ·H 2 O with 0.3g Fe(NO 3 ) 3 9H 2 O, measure 40mL of deionized water, prepare a mixed solution and heat it at 140°C for 18h for hydrothermal reaction;

[0039] Step 2: After washing and drying the product obtained in Step 1, heat it at 800° C. for 5 hours for annealing treatment;

[0040] Step 3: Place the product obtained in Step 2 in 40 mL of p-toluenesulfonic acid solution with a concentration of 0.3 mol / L and stir for 5 min, then add 20 uL of pyrrole solution and react at 5°C for 1 h;

[0041] Step 4: Pour off the supernatant of the product obtained from the reaction, then put the obtained precipitate into a centrifuge tube, wash it with deionized water first, then wash it with absolute ethanol, repeat 3 times in turn, and then put it in a drying box. Dry at 70°C for 7 hours to obtain Fe coated with polypyrrole, a pseudocapacitive material 2 o 3 / Mn 2 o 3 composite mat...

Embodiment 2

[0043] The preparation method comprises the following steps:

[0044] Step 1: Weigh 0.6g MnSO 4 ·H 2 O with 0.4g Fe(NO 3 ) 3 9H 2 O, measure 50mL of deionized water, prepare a mixed solution and heat it at 120°C for 12h for hydrothermal reaction;

[0045] Step 2: After washing and drying the product obtained in Step 1, heat it at 500° C. for 3 hours for annealing treatment;

[0046] Step 3: Put the product obtained in Step 2 in 50 mL of p-toluenesulfonic acid solution with a concentration of 0.15 mol / L and stir for 7 min, add 10 uL of pyrrole solution and react at 1°C for 3 h;

[0047] Step 4: Pour off the supernatant of the product obtained from the reaction, then put the obtained precipitate into a centrifuge tube, wash it with deionized water first, then wash it with absolute ethanol, repeat 3 times in turn, and then put it in a drying box. Dry at 60°C for 6h to obtain the pseudocapacitive material polypyrrole-coated Fe 2 o 3 / Mn 2 o 3 composite material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com