Core-shell-shaped copper selenide and ferronickel hydrotalcite electrocatalyst and preparation method and water electrolysis application thereof

A technology of copper selenide and catalyst, applied in the field of electrocatalysis, to achieve the effect of uniform size, good mechanical stability and thin sheet

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

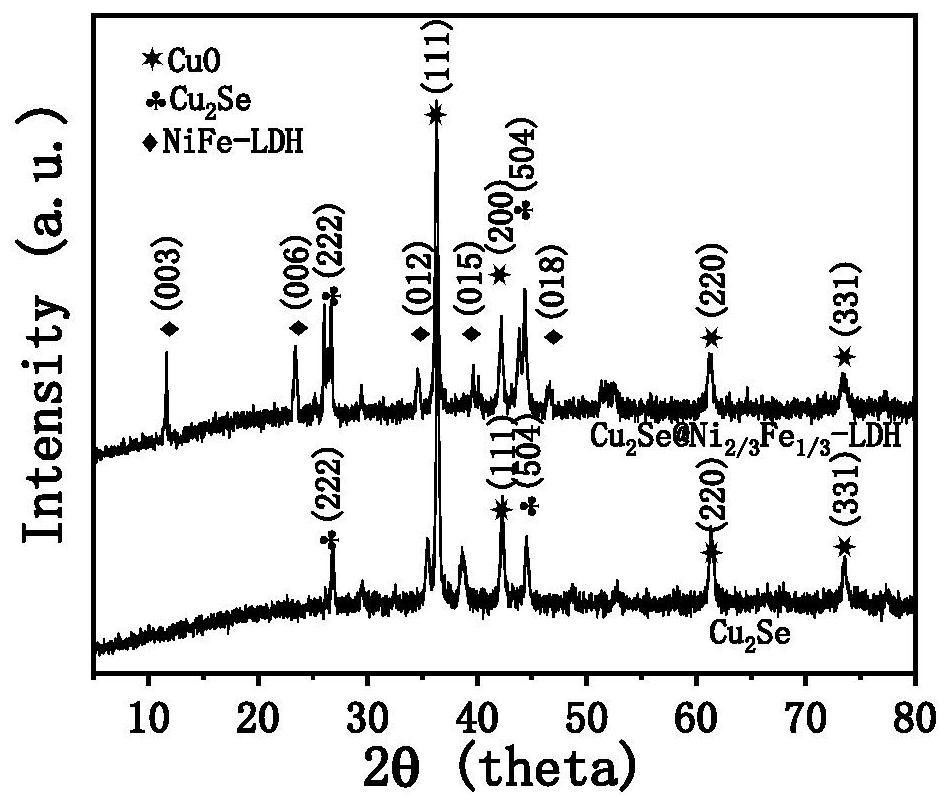

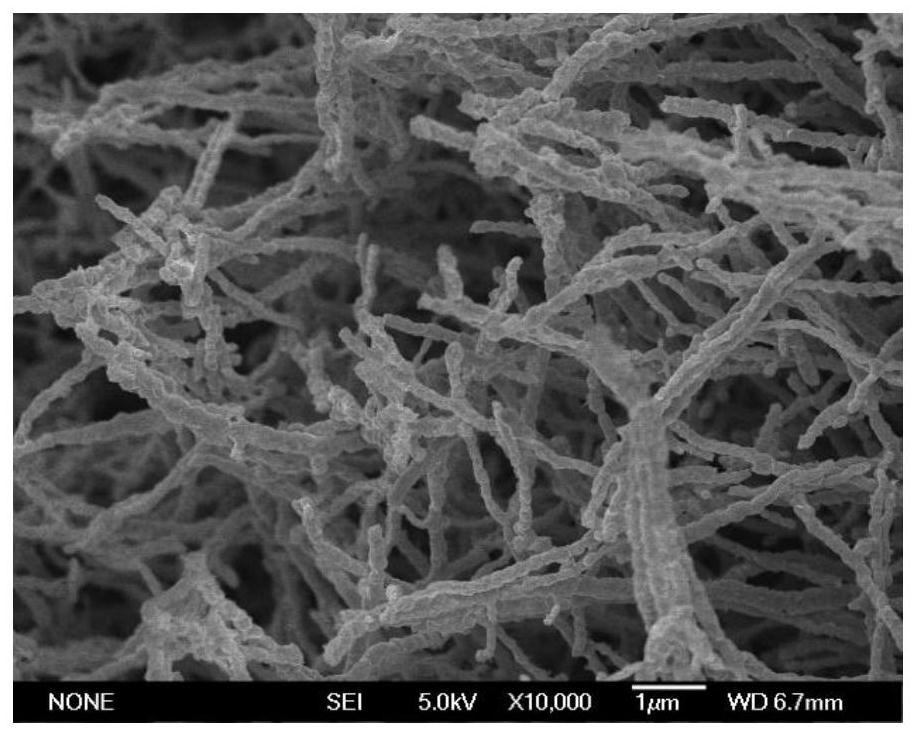

[0034] (1)Cu 2 Preparation of Se / CF

[0035] Soak the commercial copper foam with a specification of 3cm×4cm in a hydrochloric acid solution with a concentration of 37% for 10 minutes, and wash it several times with deionized water and absolute ethanol; put the cleaned foam copper into 80mL NaOH and (NH 4 ) 2 S 2 o 8 Soaked in the mixed solution for 20min to grow light blue Cu(OH) on the surface in situ 2 nanowires, grown with Cu(OH) 2 The copper foam of the nanowires was rinsed with deionized water, and dried in an oven at 60 °C for 6 h; the dried Cu(OH) 2 The nanowires are placed in a tube furnace, and 0.1g of selenium powder is placed at the front of the tube furnace, and the temperature is raised to 400 °C at a rate of 5 °C / min in a nitrogen atmosphere, and kept for 30 min. After the tube furnace cools down naturally, the sample is taken out , washed several times with deionized water and ethanol to obtain Cu 2 Se / CF, dry for later use;

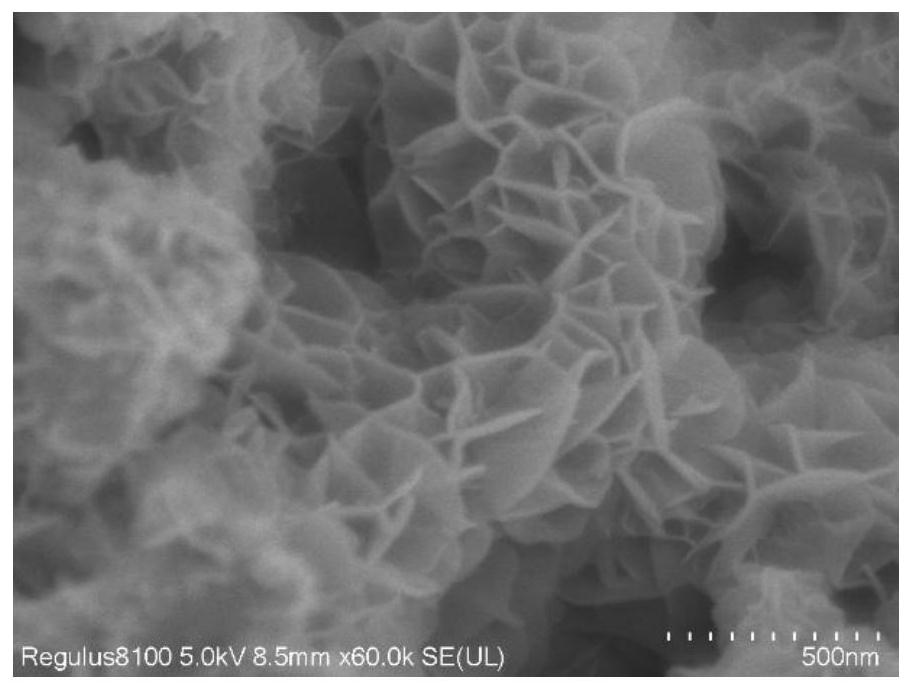

[0036] (2)Cu 2 Preparatio...

Embodiment 2

[0039] (1)Cu 2 Preparation of Se / CF

[0040] Prepare with reference to the method and conditions of step (1) in Example 1.

[0041] (2)Cu 2 Preparation of Se@NiFe-LDH / CF

[0042] Referring to the method and preparation conditions of step (2) in Example 1, the electrodeposition time was set to 60s to obtain copper selenide@nickel-iron hydrotalcite nanosheet electrocatalyst, denoted as Cu 2 Se@Ni 2 / 3 Fe 1 / 3 - LDH / CF-60;

Embodiment 3

[0044] (1)Cu 2 Preparation of Se / CF

[0045] Prepare with reference to the method and conditions of step (1) in Example 1.

[0046] (2)Cu 2 Preparation of Se@NiFe-LDH / CF

[0047] Referring to the method and preparation conditions of step (2) in Example 1, the electrodeposition time was set to 90s to obtain copper selenide@nickel-iron hydrotalcite nanosheet electrocatalyst, denoted as Cu 2 Se@Ni 2 / 3 Fe 1 / 3 - LDH / CF-90;

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com