Ethylene propylene diene monomer insulated cable material for oil-submerged pump cable and preparation method

A technology of EPDM rubber and insulating cables, which is applied in the field of materials, can solve the problems of poor oil resistance, only heat resistance, and poor high temperature resistance, and achieves optimized preparation process, good flame retardancy, and excellent insulation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

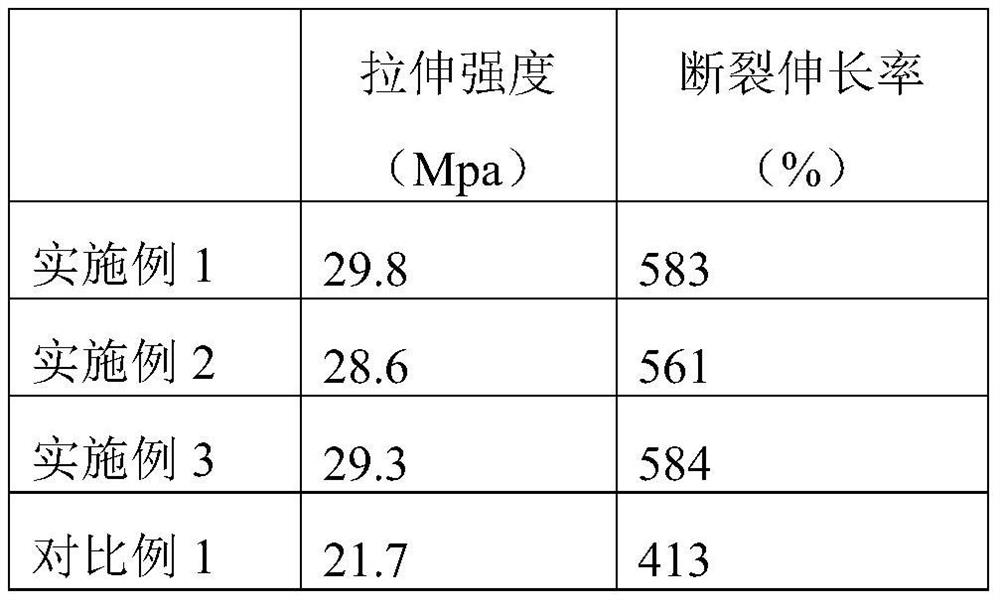

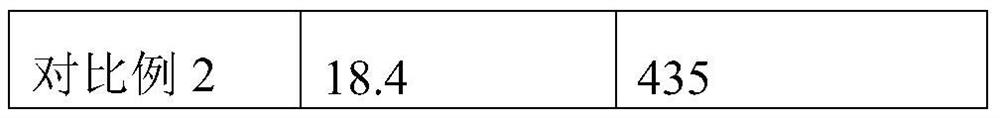

Examples

Embodiment 1

[0027] Concrete raw material is weighed by table 1, and step preparation step is as follows:

[0028] (1) Add EPDM rubber, polyperfluoroethylene propylene resin, silicone montmorillonite, basic magnesium phosphate whiskers, calcium sulfate whiskers, and carbon black into a high-speed mixer, heat up to 85 degrees Celsius, and knead for 20 minute;

[0029] (2) Add the remaining raw materials to the mixture in step (1), continue kneading for 15 minutes, discharge the material into the cooling mixer for cooling, and discharge the material when the temperature is lowered to below 50°C;

[0030] (3) the extruding temperature of setting twin-screw extruder is 190 degrees centigrade, and screw speed is 125 rev / mins, and the product that step (2) makes is added in the twin-screw extruder and carries out extrusion granulation, pellet cooling to room temperature, screen defective products, and pack to obtain the corrosion-resistant cable material.

Embodiment 2

[0032] (1) Add EPDM rubber, polyperfluoroethylene propylene resin, silicone montmorillonite, basic magnesium phosphate whiskers, calcium sulfate whiskers, and carbon black into a high-speed mixer, heat up to 95 degrees Celsius, and knead for 30 minute;

[0033] (2) Add the remaining raw materials to the mixture in step (1), continue kneading for 20 minutes, discharge the material into the cooling mixer for cooling, and discharge the material when the temperature drops below 45°C;

[0034] (3) the extruding temperature of setting twin-screw extruder is 180 degrees centigrade, and screw speed is 130 rev / mins, and the product that step (2) makes is added in the twin-screw extruder and carries out extrusion granulation, pellet cooling to room temperature, screen defective products, and pack to obtain the corrosion-resistant cable material.

Embodiment 3

[0036] The dosage is shown in Table 1, and the preparation method is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com