Mixed polycation perovskite material film with optical gain characteristic as well as preparation method and application thereof

A multi-cation, optical gain technology, applied in the field of mixed multi-cation perovskite material thin film and its preparation, can solve the problems of high current density, large non-radiative recombination, stability, poor light resistance, etc., and achieve high crystal quality, shape and shape. The appearance is smooth and flat, no pinholes, and the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0080] A method for preparing a mixed polycation material with optical gain properties, comprising the following steps:

[0081] 1) MABr, FABr, CsBr and PbBr 2 Dissolve in anhydrous dimethylsulfoxide (DMSO) according to the molar ratio of 2.2:0.05:0.05:1, heat and stir at 30°C for 20h to form [MA 0.87 (FACs) 0.13 ]PbBr 3 3D mixed-cation perovskite precursor solution at a concentration of 0.2 mol L -1 ;

[0082] 2) BABr and PbBr 2 Dissolve in anhydrous dimethyl sulfoxide (DMSO) at a ratio of 2:1 to form 2D perovskite (BA) 2 PbBr 4 Precursor solution with a concentration of 0.1mol L -1 ;

[0083] 3) Mix the precursor solutions of the above two perovskites in equal volumes to obtain a multi-cation mixed perovskite material [[MA 0.87 (FACs) 0.13 ]PbBr 3 ] 0.5 [(BA) 2 PbBr 4 ] 0.1 The precursor solution;

[0084] 4) Use a pipette gun to take 100 μL of the above-mentioned perovskite precursor solution and drop it on the glass substrate. -1 Rotate at a rotating speed...

Embodiment 2

[0087] A method for preparing a mixed polycation material with optical gain properties, comprising the following steps:

[0088] 1) FABr, MABr, CsBr and PbBr 2 Dissolve in anhydrous dimethylsulfoxide (DMSO) according to the molar ratio of 2.2:0.05:0.05:1, heat and stir at 30°C for 20h to form [FA 0.87 (MACs) 0.13 ]PbBr 3 3D mixed-cation perovskite precursor solution at a concentration of 0.5 mol L -1 ;

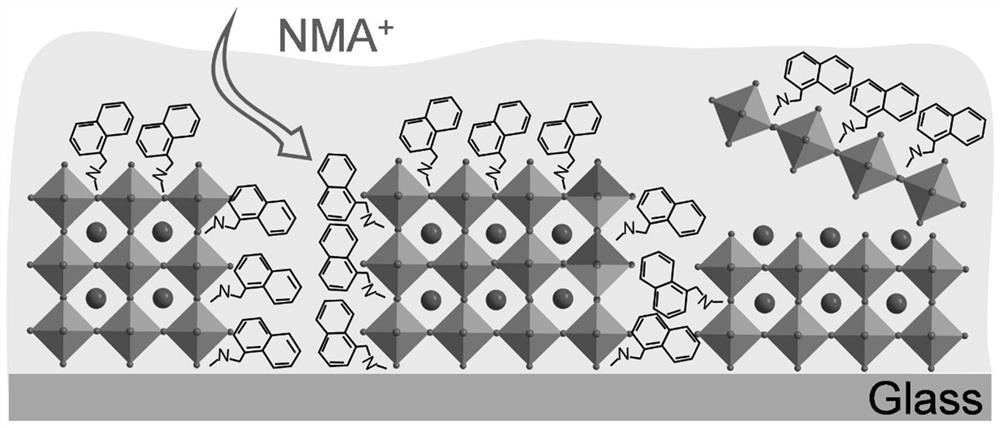

[0089] 2) NMABr and PbBr 2 Dissolved in anhydrous dimethyl sulfoxide (DMSO) at a ratio of 2:1 to form 2D perovskite (NMA) 2 PbBr 4 Precursor solution with a concentration of 0.2mol L -1 ;

[0090]3) Mix the precursor solutions of the above two perovskites in equal volumes to obtain a multi-cation mixed perovskite material [[FA 0.87 (MACs) 0.13 ]PbBr 3 ] 0.5 [(NMA) 2 PbBr 4 ] 0.2 The precursor solution;

[0091] 4) Use a pipette gun to take 60 μL of the above-mentioned perovskite precursor solution and drop it on the glass substrate. -1 The rotation speed is ro...

Embodiment 3

[0094] A method for preparing a mixed polycation material with optical gain properties, comprising the following steps:

[0095] 1) CsBr, MABr, FABr and PbBr 2 Dissolve in anhydrous N-N dimethylformamide (DMF) according to the molar ratio of 2.2:0.01:0.09:1, heat and stir at 35°C for 20h to form [Cs 0.87 (MAFA) 0.13 ]PbBr 3 3D mixed cation perovskite precursor solution with a concentration of 0.5mol L -1 ;

[0096] 2) PEABr and PbBr 2 Dissolve in anhydrous N-N dimethylformamide (DMF) at a ratio of 2:1 to form 2D perovskite (PEA) 2 PbBr 4 Precursor solution with a concentration of 0.2mol L -1 ;

[0097] 3) Mix the precursor solutions of the above two perovskites in equal volumes to obtain a multi-cation mixed perovskite material [[Cs 0.87 (MAFA) 0.13 ]PbBr 3 ] 0.5 [(PEA) 2 PbBr 4 ] 0.2 The precursor solution;

[0098] 4) Use a pipette gun to take 50 μL of the above-mentioned perovskite precursor solution and drop it on the glass substrate. -1 Rotate at a rotati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Roughness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com