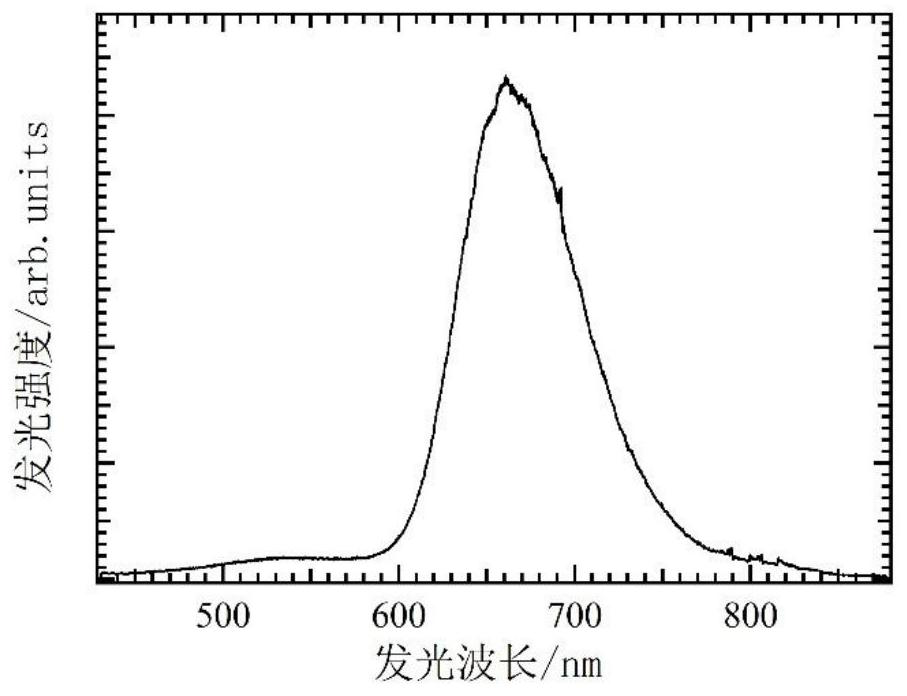

Preparation method of InGaN/GaN multi-quantum well-based red light LED structure

A technology of LED structure and multiple quantum wells, which is applied in the field of microelectronics, can solve problems that are not conducive to the thermodynamic balance of In atom relaxation, high strain energy, strong quantum confinement Stark effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

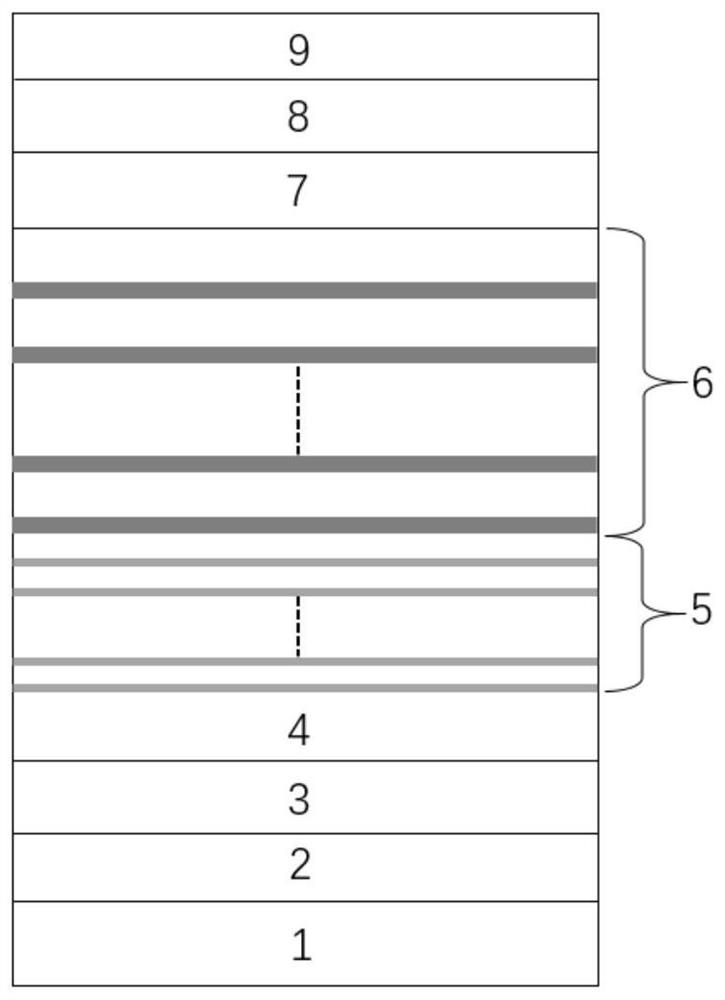

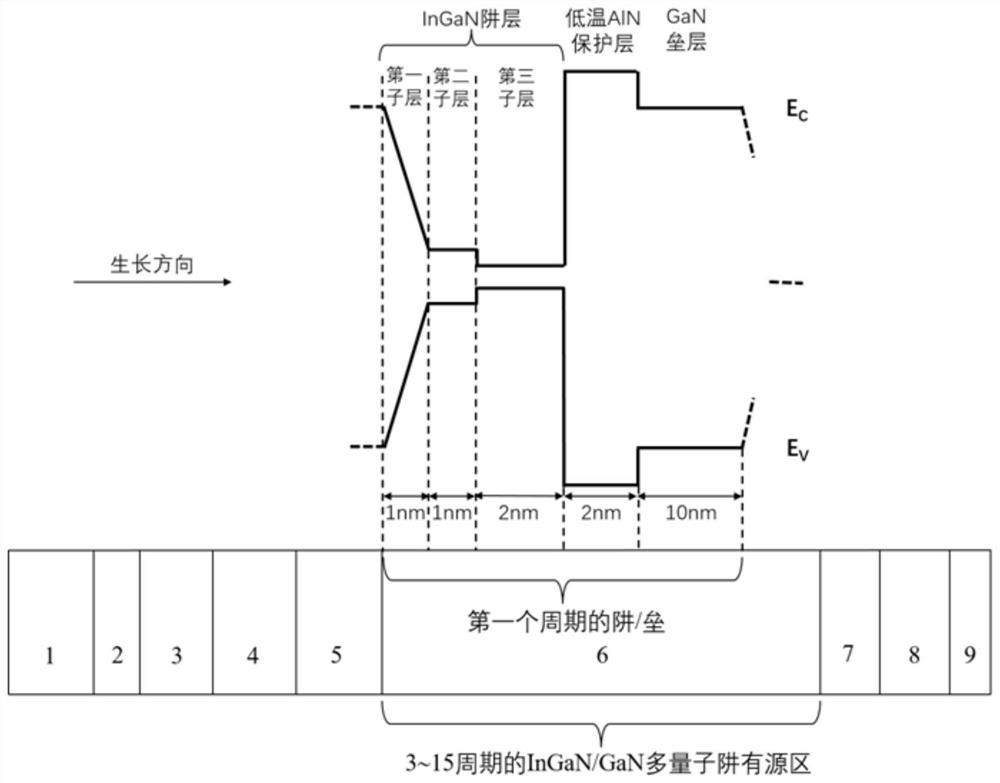

[0070] A method for preparing an InGaN / GaN multi-quantum well-based red light LED structure, such as figure 1 As shown, the InGaN / GaN multi-quantum well-based red LED structure grows sequentially from bottom to top with a sapphire substrate 1, a low-temperature GaN buffer layer 2, an undoped GaN layer 3, an n-type GaN layer 4, and an InGaN / GaN supercrystal Lattice stress release layer 5, InGaN / GaN multi-quantum well active region 6, p-type AlGaN electron blocking layer 7, p-type GaN layer 8, p-type InGaN ohmic contact layer 9, InGaN / GaN multi-quantum well active region 6 includes Several cycles of InGaN / GaN multiple quantum wells. InGaN / GaN multiple quantum wells include InGaN well layers, low-temperature AlN protective layers, and GaN barrier layers that grow sequentially from bottom to top. The first sub-layer, the second sub-layer, and the third sub-layer include the following steps:

[0071] (1) On a sapphire substrate 1 (Al 2 o 3 ) on which a low-temperature GaN buffer...

Embodiment 2

[0083] According to the preparation method of a kind of InGaN / GaN multi-quantum well-based red light LED structure described in embodiment 1, its difference is:

[0084] The following steps are performed between step A and step B: keep the temperature in the reaction chamber constant, turn off trimethylgallium (Ga source), only pass on trimethylindium (In source), and pause for 10-30s.

[0085] The method can effectively suppress In volatilization, and at the same time, allow In atoms in the well layer, especially the In atoms on the surface of the well layer, to have sufficient time to relax to a suitable lattice position and reach thermodynamic equilibrium.

Embodiment 3

[0087] According to the preparation method of a kind of InGaN / GaN multi-quantum well-based red light LED structure described in embodiment 1, its difference is:

[0088] The following steps are performed between step A and step B: keep the temperature in the reaction chamber constant, turn off trimethylgallium (Ga source), only pass on trimethylindium (In source), and pause for 25s.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com