Red organic electroluminescent material and preparation method thereof

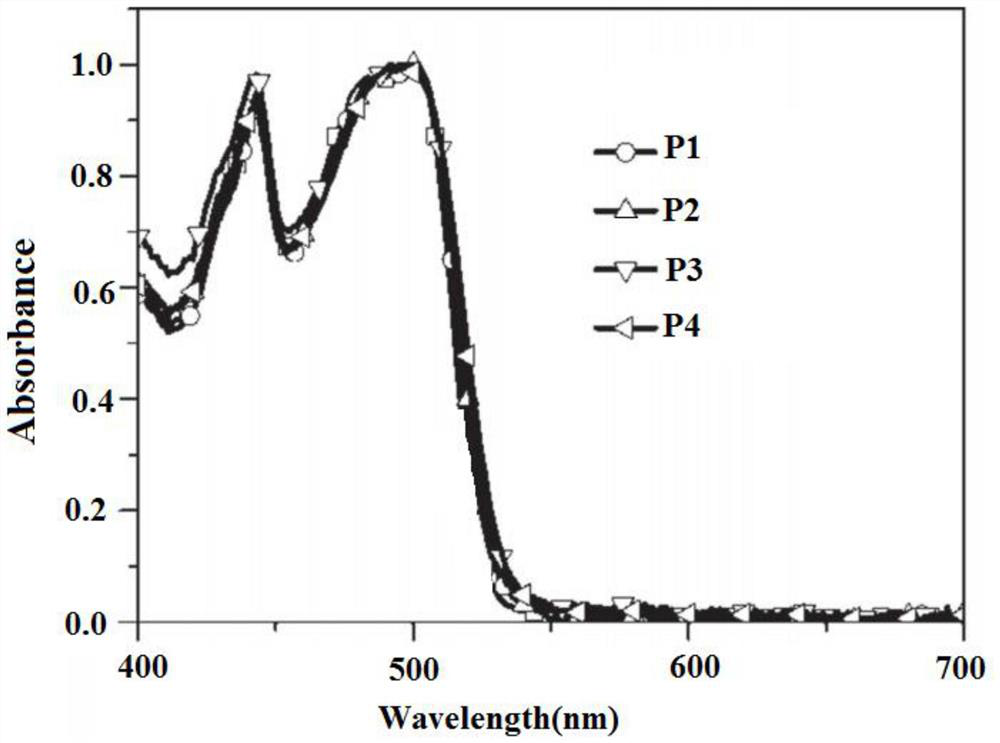

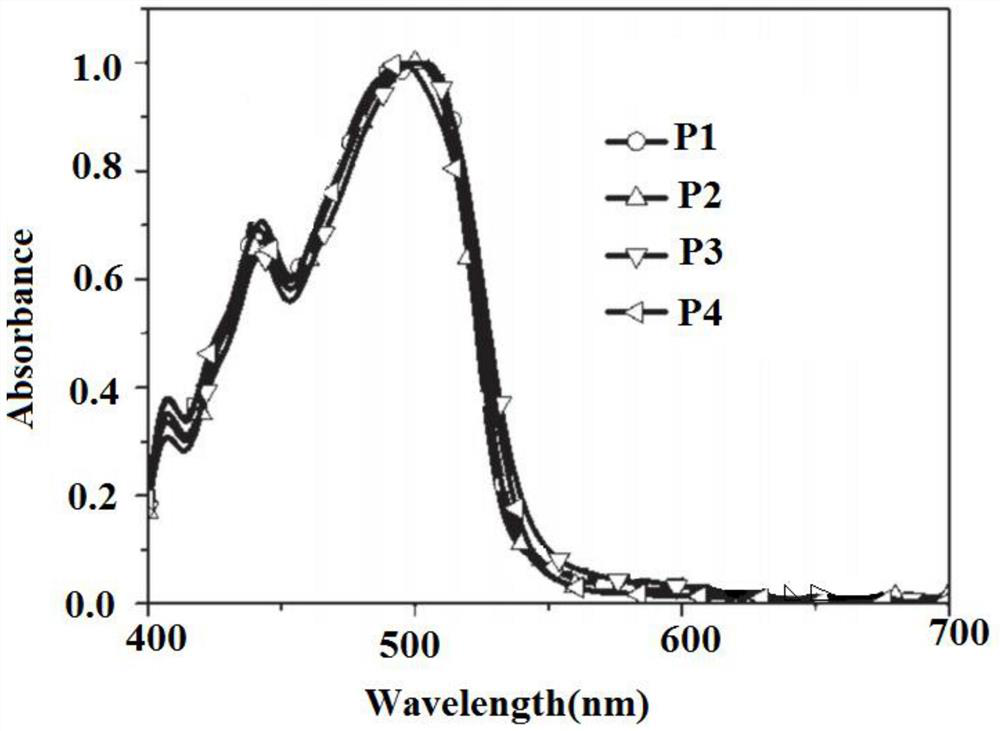

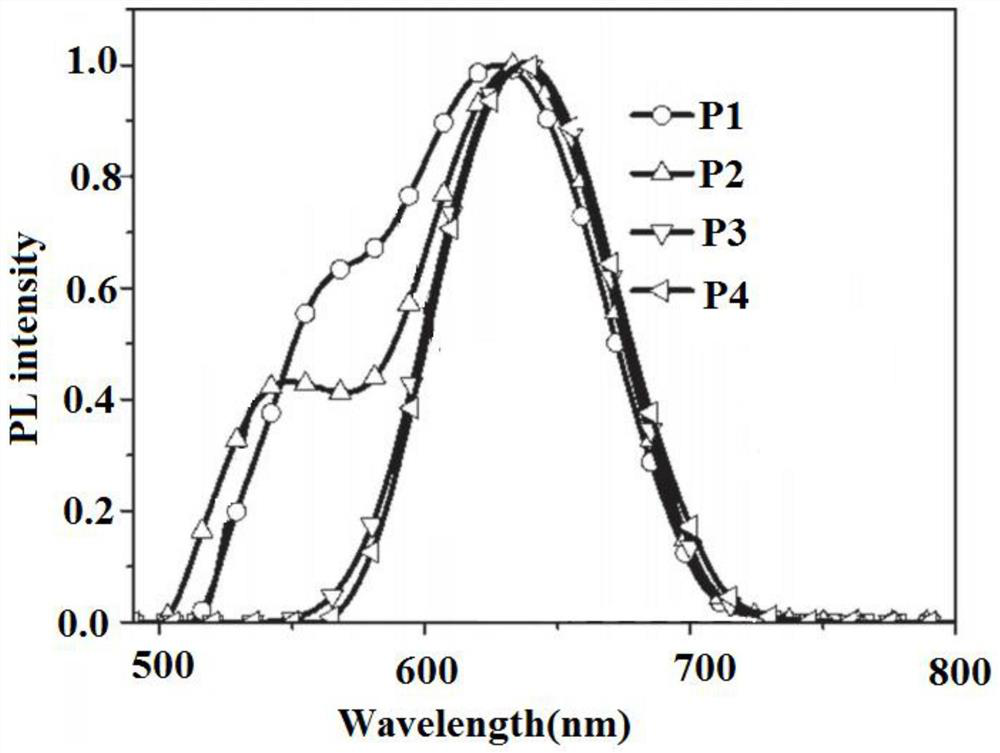

An electroluminescence, electromechanical technology, applied in the preparation of luminescent materials, organic compounds, hydrocarbon production from halogen-containing organic compounds, etc., can solve problems such as poor luminescence performance, and achieve enhanced electroluminescence efficiency and strong spectral stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Dissolve 4,4'-dibromobiphenyl (15.6g, 50mmol) in 150mL of acetic acid, stir in the dark under ice bath, take 30ml of fuming nitric acid and dilute with 50ml of acetic acid, add it to the constant pressure dropping funnel, under the condition of dark Slowly add it dropwise to the reaction solution. After the dropwise addition, slowly raise the reaction temperature to 85°C and reflux for 2 hours. Observe the change of the reaction solution. When the reaction solution turns from turbid to transparent, stop the reaction and cool down to room temperature naturally. The reaction solution was slowly poured into ice water to quench, the mixture was suction filtered, the filter residue was washed with water, saturated aqueous sodium bisulfite solution, water, and ice ethanol, and then the filter residue was dried to obtain 4,4'-dibromo-2-nitrate Base biphenyl (12.7g, productive rate 63%), its reaction equation is as follows:

[0019]

Embodiment 2

[0021] Dissolve 4,4'-dibromo-2-nitrobiphenyl (14.28 g, 40 mmol) and triphenylphosphine (26.2 g, 100 mmol) in 250 ml of N,N-dimethylacetamide (DME), argon Heated and stirred overnight in an air atmosphere. Stop the reaction and cool to room temperature, extract with dichloromethane and wash with water 3-5 times, purify by column chromatography, use 200-300 mesh silica gel as stationary phase, petroleum ether / dichloromethane (2:1) as washing Remove the agent and carry out silica gel column chromatography, and the crude product is recrystallized with ethanol to obtain 2,7-dibromocarbazole (9.7g, yield 74%), and its reaction equation is as follows:

[0022]

Embodiment 3

[0024] Dissolve 2,7-dibromocarbazole (6.5g, 20mmol) in 50ml of N,N-dimethylformamide (DMF), add potassium hydroxide (2.7g, 48mmol), stir at room temperature for 30min, then add 2 -(3-Bromophenyl)-5-phenyl-1,3,4-oxadiazole (12.94g, 43mmol), after the dropwise addition, continued to stir at 85°C for 10h. After the reaction was completed, the reaction solution was poured into water, and a light yellow solid was precipitated. The solid was filtered under reduced pressure, rinsed with distilled water several times, and dried under reduced pressure to obtain 2-(3-(2,7-dibromo9H-carbazol-9-yl)phenyl)-5-phenyl -1,3,4-oxadiazole (9.8g, yield 90%), the chemical equation of this reaction is:

[0025]

PUM

| Property | Measurement | Unit |

|---|---|---|

| luminance | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com