Preparation method of Sanjin micro-capsule preparation

A preparation and capsule material technology, which is applied in the preparation of Sanjin microcapsule preparations, can solve problems such as unacceptable by consumers, easy moisture deterioration of tablets, and influence on treatment effects, etc., to achieve improved encapsulation effect, stable properties, and prolonged storage period effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

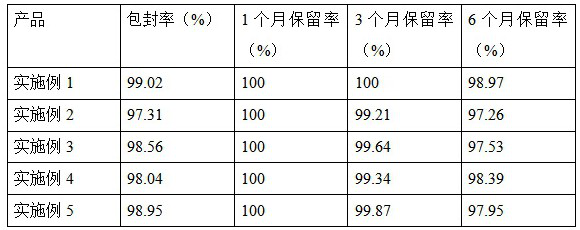

Examples

Embodiment 1

[0028] A preparation method of Sanjin microcapsule preparation, comprising the steps of:

[0029] (1) Put golden cherry root, smilax, yangkaikou, jinshateng and centella asiatica in the extraction tank according to the weight ratio of 10:5:5:3:3, add water 6 times the weight of the medicinal materials and decoct 3 times, Decoct for 2 hours each time, filter, combine the filtrates, and concentrate at a pressure of -0.06Mpa and a temperature of 75°C to a solid content of 55% to obtain Sanjin extract, which is then passed through a pulse air dryer at a temperature of 80°C and wind speed Dry at 15m / s to get Sanjin powder;

[0030] (2) Add tea saponin, rhamnolipid, konjac gum, carrageenan and gum arabic into water according to the mass ratio of 4:3:5:8:12 to form a solution with a mass fraction of 32%, heat and stir evenly , to obtain the cyst material liquid;

[0031] (3) Add Sanjin powder, plasticizer and capsule material liquid into a homogenizer, and perform homogenization tr...

Embodiment 2

[0034] A preparation method of Sanjin microcapsule preparation, comprising the steps of:

[0035] (1) Put golden cherry root, smilax, yangkaikou, jinshateng and centella asiatica in the extraction tank according to the weight ratio of 10:5:5:3:3, add water 7 times the weight of the medicinal materials and decoct twice, Decoct for 2.5 hours each time, filter, combine the filtrates, and concentrate at a pressure of -0.08Mpa and a temperature of 65°C to a solid content of 50% to obtain Sanjin extract, which is then passed through a pulse air dryer at a temperature of 100°C. Dry at a wind speed of 15m / s to obtain Sanjin powder;

[0036] (2) Add tea saponin, rhamnolipid, konjac gum, carrageenan and gum arabic into water at a mass ratio of 3:2:4:7:15 to form a solution with a mass fraction of 28%, heat and stir evenly , to obtain the cyst material liquid;

[0037] (3) Add Sanjin powder, plasticizer and capsule material liquid into the homogenizer, and perform homogenization treatm...

Embodiment 3

[0040] A preparation method of Sanjin microcapsule preparation, comprising the steps of:

[0041] (1) Put golden cherry root, smilax, yangkaikou, jinshateng and centella asiatica in the extraction tank according to the weight ratio of 10:5:5:3:3, add water 5 times the weight of the medicinal materials and decoct 3 times, Decoct for 2 hours each time, filter, combine the filtrates, and concentrate at a pressure of -0.08Mpa and a temperature of 70°C to a solid content of 50% to obtain Sanjin extract, and then pass through a pulse air dryer at a temperature of 90°C and a wind speed of Dry at 12m / s to get Sanjin powder;

[0042] (2) Add tea saponin, rhamnolipid, konjac gum, carrageenan and gum arabic into water at a mass ratio of 5:2:3:8:12 to form a solution with a mass fraction of 28%, heat and stir evenly , to obtain the cyst material liquid;

[0043] (3) Add Sanjin powder, plasticizer and capsule material liquid into the homogenizer, and perform homogenization treatment at a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com