Preparation process for improving phloroglucinol by membrane method

A technology for phloroglucinol and preparation process, which is applied in the preparation of organic compounds, chemical instruments and methods, and hydrocarbon production from halogen-containing organic compounds, etc., can solve the problems of long process, difficult disposal of waste salt, generation of by-products, etc. , to achieve the effect of simple reaction process, satisfying recycling and high relative efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

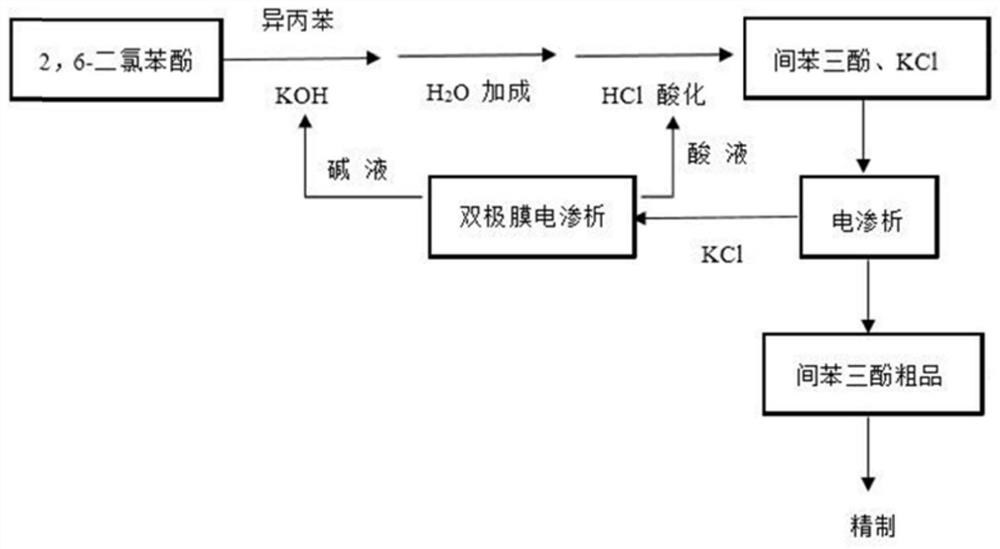

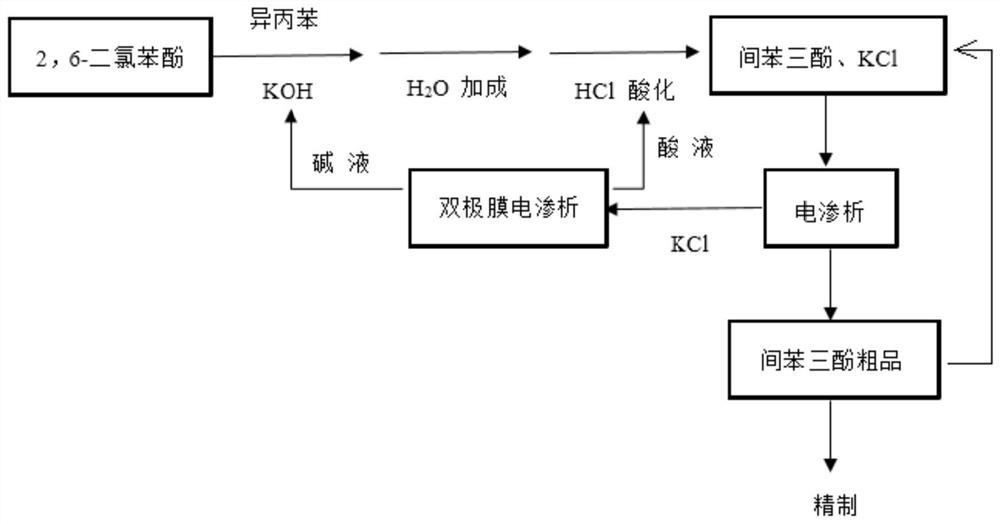

[0040] Adopt method of the present invention to prepare phloroglucinol, concrete technological process is as follows:

[0041] S1. Select cumene, an inert solvent with a density lower than water, immiscible with water and capable of azeotroping, to dissolve the reaction substrate 2,6-dichlorophenol to obtain solution A. Mix solution A and potassium hydroxide solution at a molar ratio of 1:10, then add water, and finally add hydrochloric acid solution to acidify to prepare a mixed solution of phloroglucinol and potassium chloride.

[0042] S2. The mixed solution of phloroglucinol and potassium chloride is firstly pretreated by precision filtration with a 0.5 μm filter membrane to remove suspended solids and macromolecular phloroglucinol crystals. Then the filtered mixed solution is passed into an electrodialysis system to obtain crude phloroglucinol and potassium chloride solution respectively. During the electrodialysis process, water needs to be added to the dilute chamber r...

Embodiment 2

[0045] Adopt method of the present invention to prepare phloroglucinol, concrete technological process is as follows:

[0046] S1. Select cumene, an inert solvent with a density lower than water, immiscible with water and capable of azeotroping, to dissolve the reaction substrate 2,6-dichlorophenol to obtain solution A. Mix solution A and potassium hydroxide solution at a molar ratio of 1:10, then add water, and finally add hydrochloric acid solution to acidify to prepare a mixed solution of phloroglucinol and potassium chloride.

[0047] S2. The mixed solution of phloroglucinol and potassium chloride is pretreated by precision filtration with a filter membrane of 1 μm, so as to remove suspended solids and macromolecular phloroglucinol crystals. Then the filtered mixed solution is passed into an electrodialysis system to obtain crude phloroglucinol and potassium chloride solution respectively. During the electrodialysis process, water needs to be added to the dilute chamber r...

Embodiment 3

[0050] This embodiment is used as a comparative example of Example 1 to explore the effectiveness of two-step electrodialysis in the present invention. The specific practices of this embodiment are as follows:

[0051] S1. Select cumene, an inert solvent with a density lower than water, immiscible with water and capable of azeotroping, to dissolve the reaction substrate 2,6-dichlorophenol to obtain solution A. Mix solution A and potassium hydroxide solution at a molar ratio of 1:10, then add water, and finally add hydrochloric acid solution to acidify to prepare a mixed solution of phloroglucinol and potassium chloride.

[0052] S2. The mixed solution of phloroglucinol and potassium chloride is firstly pretreated by precision filtration with a 0.5 μm filter membrane to remove suspended solids and macromolecular phloroglucinol crystals. Then, the filtered mixed solution is separated by electrodialysis, and the operation process of the system and the difference of the obtained p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com