A kind of alkaline foam cleaning agent for farm and preparation method thereof

A foam cleaning agent, a technology for breeding farms, applied in the directions of surface active detergent compositions, detergent compounding agents, detergent compositions, etc. The method is simple, the number of bacteria is reduced, and the effect of a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

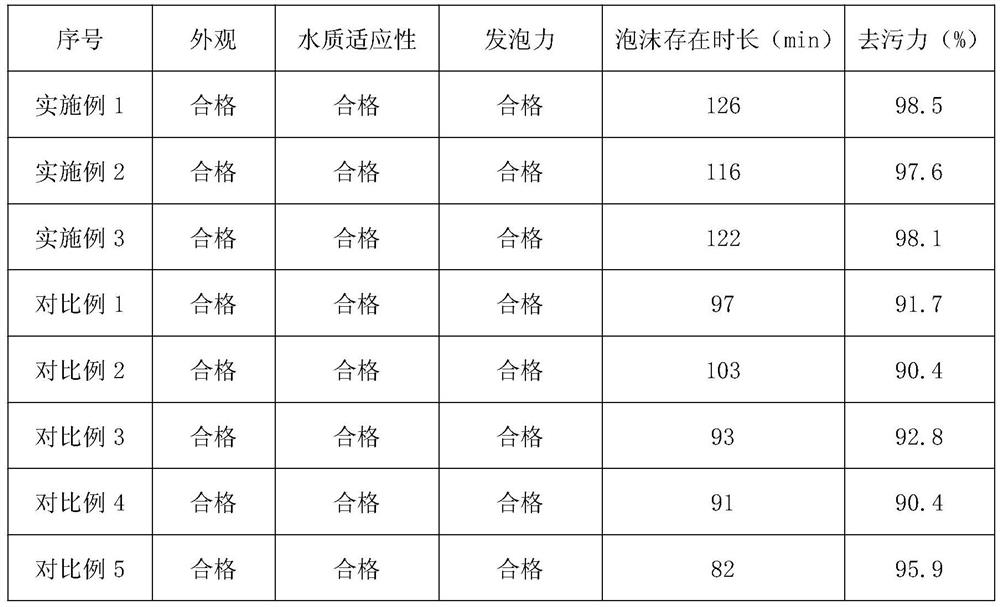

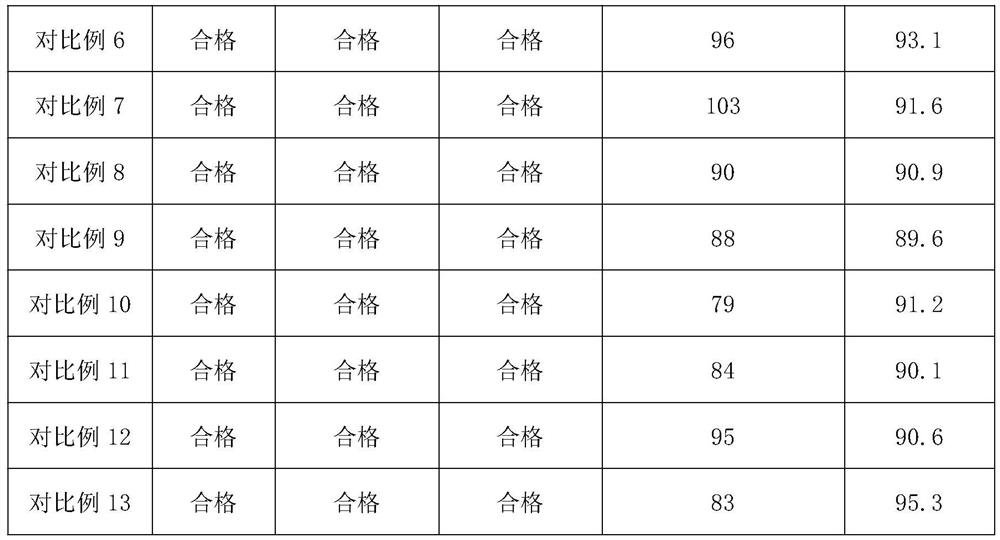

Examples

Embodiment 1

[0027] (1) After mixing and dissolving 55g of alkyl glucoside and 547g of water, add 100g of sodium hydroxide, stir and cool to obtain mixed solution A;

[0028] (2) Add 50g of disodium edetate, 18g of triethanolamine and 170g of composite foaming agent in mixed solution A, after stirring uniformly, obtain mixed solution B; It is composed of 9:4:4 sodium α-alkenyl sulfonate, sodium salt of α-sulfo fatty acid methyl ester and sodium dodecylbenzene sulfonate.

[0029] (3) Add 35 g of lauryl ammonium oxide and 25 g of isomeric alcohol polyoxyethylene ether into the mixed liquid B, stir evenly, and obtain an alkaline foam cleaning agent.

Embodiment 2

[0031] (1) After mixing and dissolving 50g of alkyl glucoside and 625g of water, add 80g of sodium hydroxide, stir and cool to obtain mixed solution A;

[0032] (2) Add 40g of disodium edetate, 15g of triethanolamine and 140g of composite foaming agent in mixed solution A, after stirring, obtain mixed solution B; It is composed of 8:3:3 sodium α-alkenyl sulfonate, sodium salt of α-sulfo fatty acid methyl ester and sodium dodecylbenzene sulfonate.

[0033] (3) Add 30 g of silicone resin polyether emulsion and 20 g of isomeric alcohol polyoxyethylene ether into the mixed solution B, and stir evenly to obtain an alkaline foam cleaning agent.

Embodiment 3

[0035] (1) After mixing and dissolving 60g of alkyl glucoside and 470g of water, add 120g of sodium hydroxide, stir and cool to obtain mixed solution A;

[0036] (2) Add 60g of disodium edetate, 20g of triethanolamine and 200g of composite foaming agent in mixed solution A, after stirring uniformly, obtain mixed solution B; Described composite foaming agent is obtained by mass ratio It is composed of sodium α-alkenylsulfonate, sodium salt of α-sulfo fatty acid methyl ester and sodium dodecylbenzenesulfonate in a ratio of 10:5:5.

[0037] (3) Add 20g of lauryl ammonium oxide, 20g of silicone resin polyether emulsion and 30g of isomeric alcohol polyoxyethylene ether into the mixed solution B, stir evenly to obtain an alkaline foam cleaning agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com