Positive electrode active material and preparation method thereof, secondary battery positive electrode and lithium battery

A positive electrode active material and secondary battery technology, which is applied in the field of materials, can solve the problems of limited stability improvement of lithium cobalt oxide materials, and achieve the effects of improving cycle stability and improving harmful reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0059] The present application also provides a method for preparing the above-mentioned positive electrode active material, including:

[0060] first doping boron in the lithium-containing compound particles, and then doping nickel;

[0061] Or, doping nickel in the lithium-containing compound particles first, and then doping boron;

[0062] Alternatively, boron and nickel are doped together in the lithium-containing compound particles.

[0063] In other words, in this application, nickel and boron can be doped simultaneously, or one can be doped first, and then the other can be doped.

[0064] In the embodiment of this application, doping is performed by sintering. It can be understood that in other embodiments of this application, other methods can be used for doping. In this embodiment, high temperature sintering is used. Doping is described as an example.

[0065] For example, the boron source, the nickel source, the fusion agent and the lithium-containing compound part...

Embodiment 1

[0089] This embodiment provides a positive electrode active material, which is mainly prepared by the following method:

[0090] 50g of LiCo 0.98 al 0.02 o 2 Material, 0.2g H 3 BO 3 , 0.15g NiO, 2g sucrose and 20g deionized water were evenly mixed, and the resulting mixture was dried in a 120°C water bath environment, and the above-mentioned dried mixture was calcined at 800°C for 5h, and the heating rate was 3°C / min. After the calcination was completed, Decrease to room temperature at a rate of 5°C / min.

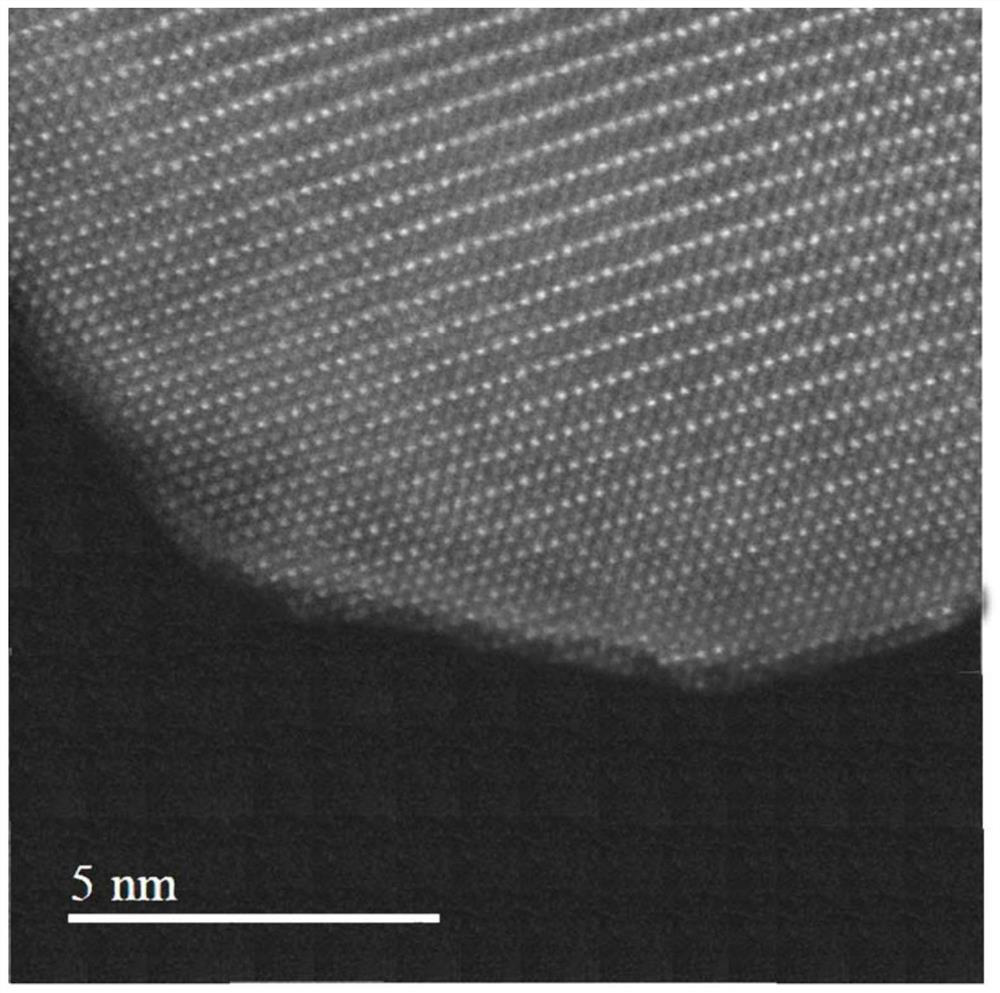

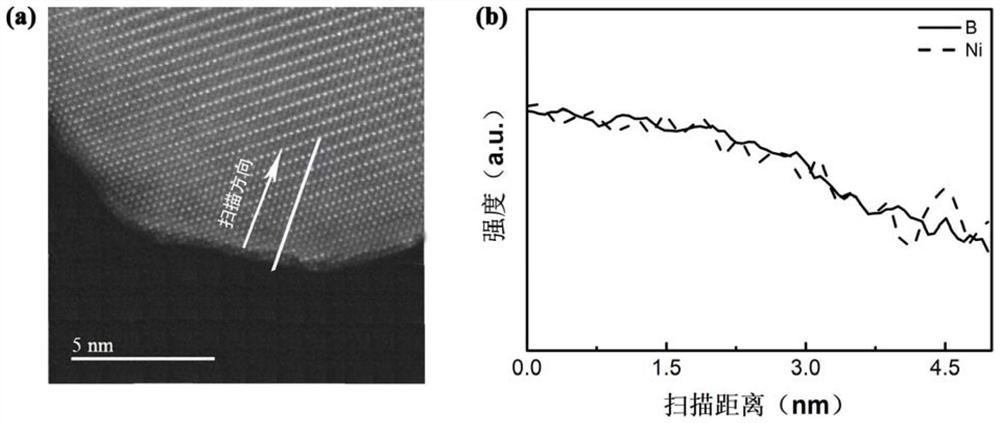

[0091] figure 1 A STEM image of the positive electrode active material provided in Example 1 of the present application is shown. figure 2 A STEM line scan image of the surface of the positive electrode active material provided in Example 1 of the present application is shown.

[0092] from figure 1 and figure 2 It can be seen that the contents of boron and nickel elements gradually decrease from the surface to the interior.

Embodiment 2

[0094] This embodiment provides a positive electrode active material, which is mainly prepared by the following method:

[0095] 50g of LiCo 0.98 al 0.02 o 2 Material, 0.15g B 2 o3 , 0.15g NiO were evenly mixed, and the resulting mixture was calcined in air at 800°C for 5h with a heating rate of 3°C / min, and after the calcination was completed, the rate was lowered to room temperature at a rate of 5°C / min.

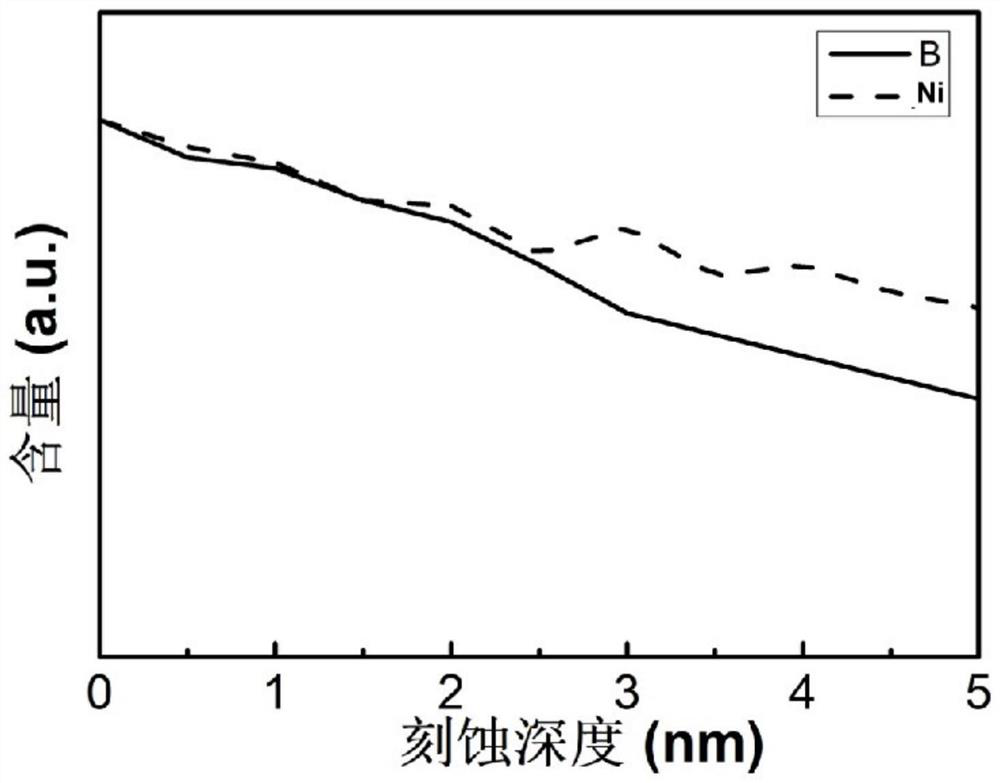

[0096] image 3 The XPS characterization diagram of the cathode active material provided in Example 2 is shown. image 3 It can be seen that: LiCo doped with boron and nickel elements 0.98 Al 0.02 o 2 The relative content changes of boron and nickel elements on the surface obtained by XPS characterization at different etching depths, we can see that the content of boron and nickel elements decreases from the surface to the interior as the etching depth increases.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com