High-voltage-resistant all-solid-state lithium battery interface layer and in-situ preparation method and application thereof

An in-situ preparation and interfacial layer technology, which is applied in the manufacture of electrolyte batteries, secondary batteries, solid electrolytes, etc., can solve problems such as the formation of space charge layers, poor contact, and increased contact resistance, so as to increase the oxidation decomposition potential and reduce Effects of interface resistance and specific energy improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

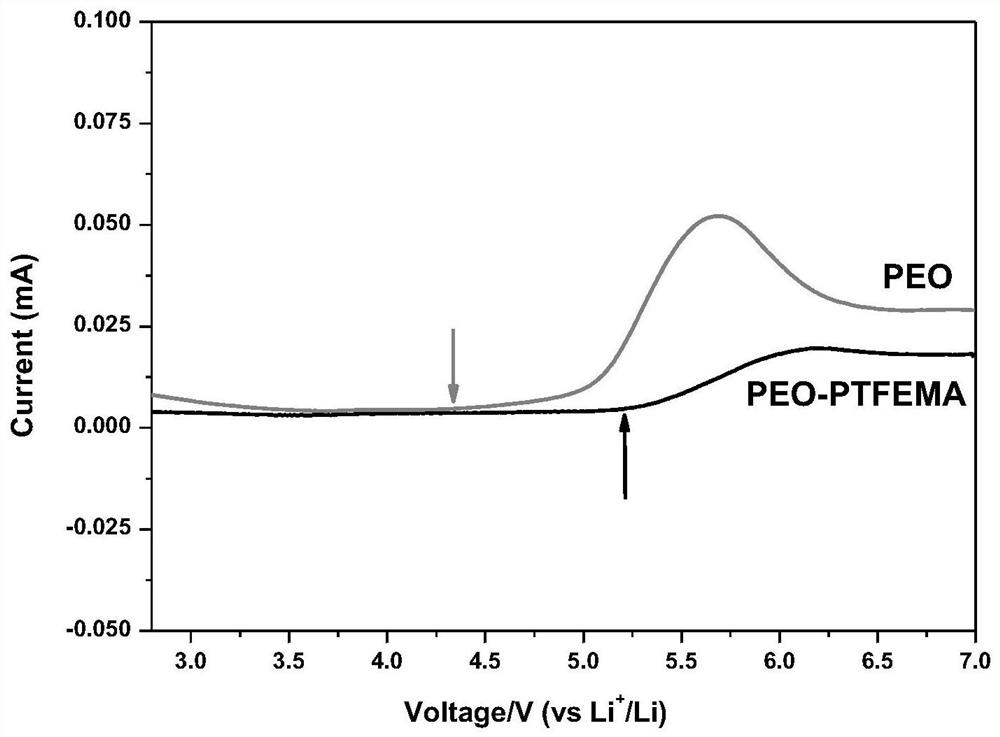

[0034] (1) Precursor preparation: 100g trifluoroethyl methacrylate monomer and 100g lithium trifluoromethanesulfonylimide LiTFSI were mixed in an inert gas-protected glove box, and 3g initiator azobisisobutyronitrile ( AIBN), stirring for 4h until the lithium salt is fully dissolved, the water content in the glove box is less than 0.1ppm, and the oxygen content is less than 0.1ppm;

[0035] (2) Assemble the battery, smear the precursor on the opposite side between the positive electrode and the ether-based electrolyte matrix, and assemble the prepared positive electrode, negative electrode and ether-based electrolyte matrix into a battery in the glove box;

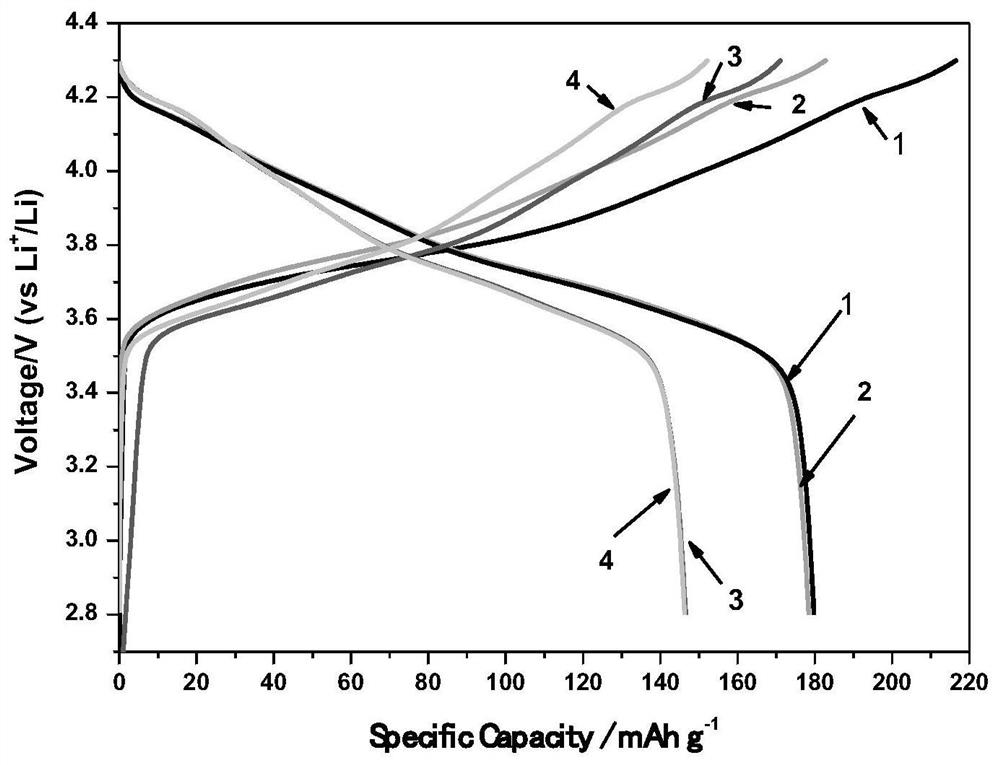

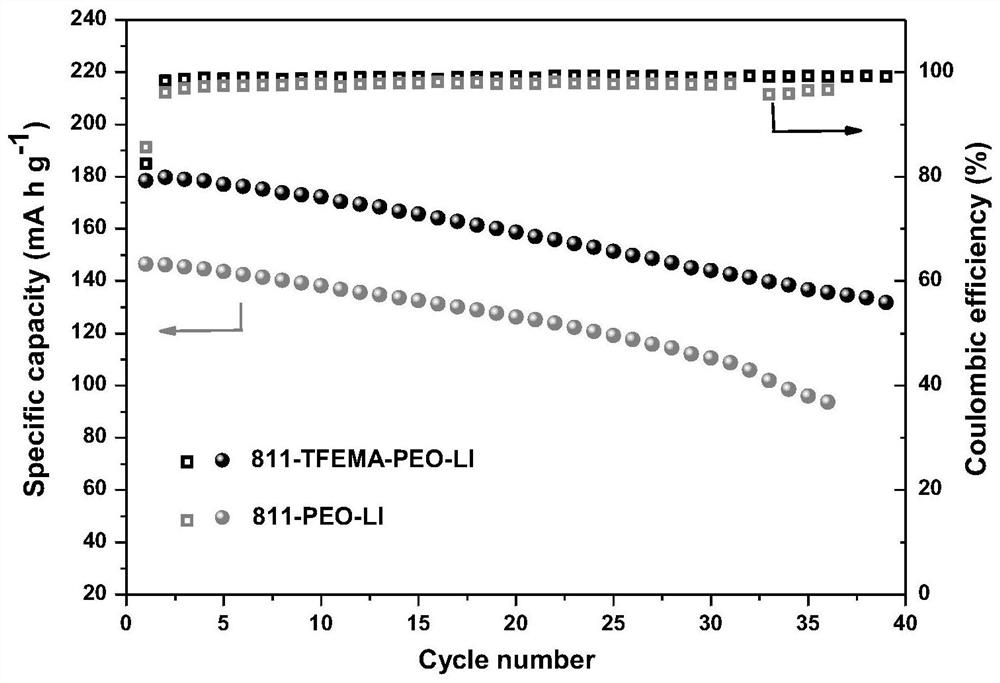

[0036] (3) Electrochemically initiate polymerization, transfer the assembled battery to an oven, set the oven temperature to 60 degrees Celsius, keep warm for 2 hours, charge the battery, set the current rate to 0.1C, and start from the initial voltage of 2.8V. Flow charging, charge to 4.3V stop.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com