A kind of fermentation method that improves L-isoleucine yield

A technology of isoleucine yield and isoleucine is applied in the field of fermentation to improve L-isoleucine yield, and can solve the problems of low acid production rate, low sugar-acid conversion rate and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] Constructed for L- isoleucine-producing strains of engineering: Example 1

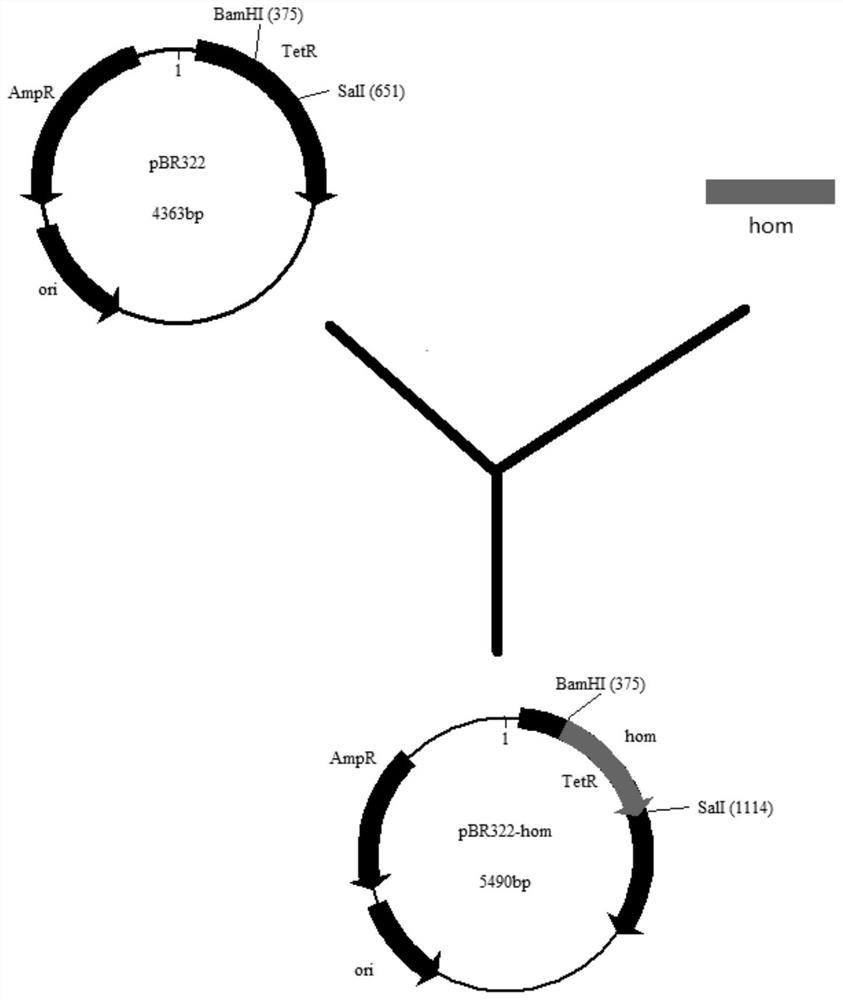

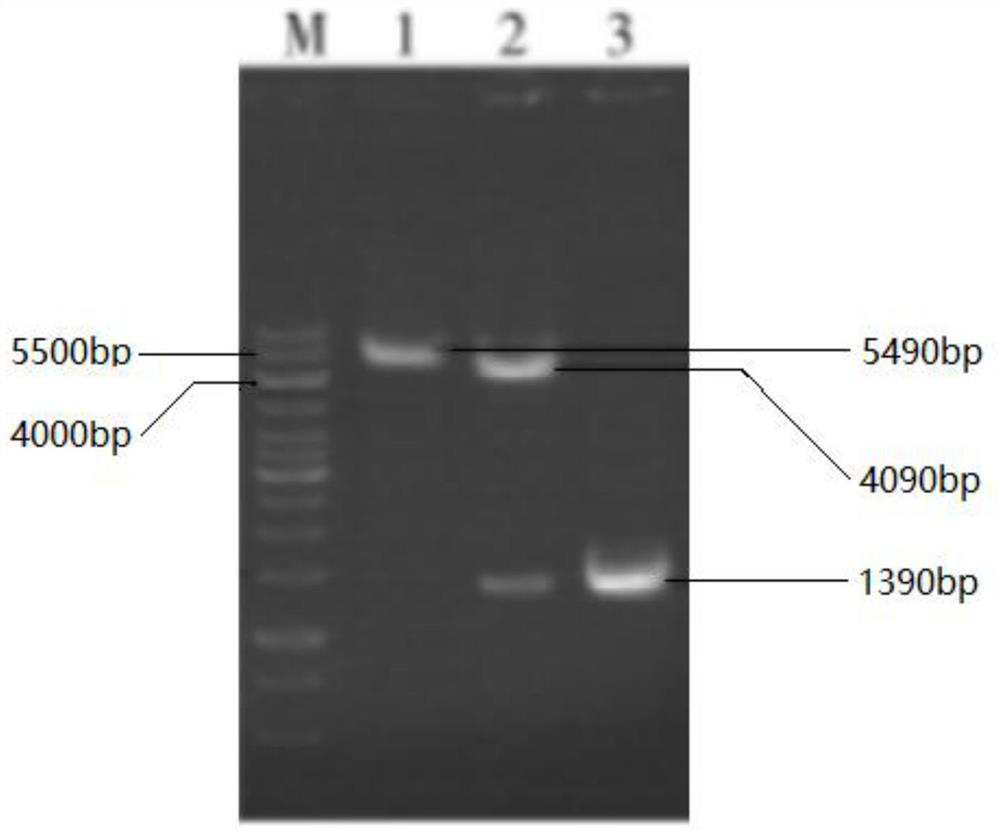

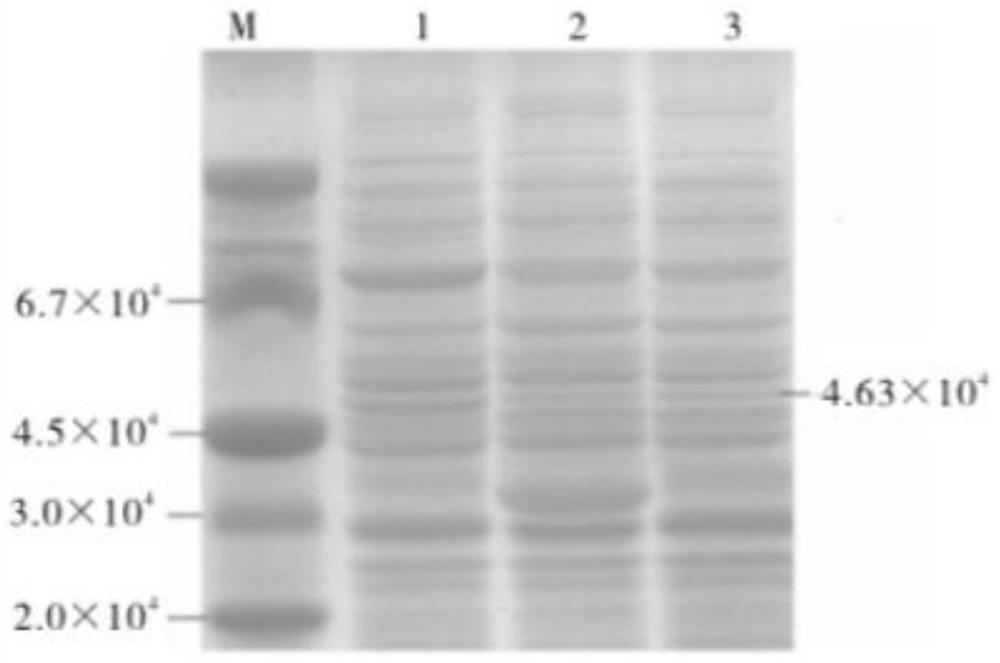

[0068] In L- isoleucine producing bacteria C.glutamicumYILW genomic chromosomal DNA as a template, P1 (5'-CGGCTA Gtcgac GTTCAATTGCCATGTCAGT-3 ', as the scribing Sal I restriction site; SEQ ID NO.1) and P2 (5'-GCGCCGA GGATCC GTAATAGGACAACAACGC TC-3 ', as the scribing BamH I restriction site; SEQ ID NO.2) as primers, PCR amplified homoserine dehydratase gene encoding hom. Using BamH I and Sal I and the PCR product was double digested pBR322 plasmid, the ligation product into the chemical transformation E.coli DH5a, cultured on LB plates at a final concentration of 25ug / mL ampicillin 37 ℃. Using primers P3 (5'-GACAATTAATCATCGGCTCG-3 '; SEQ ID NO.3), P4 (5'-CAGGCTGAAA ATCTTCTCTC-3'; SEQ ID NO.4) identified transformants to grow, positive clones, digested verification, sequencing. In L- isoleucine producing bacteria C.glutamicum YILW cloned genomic DNA as template hom gene fragment was connected to dou...

Embodiment 2

[0071] L- isoleucine Production Example 2:

[0072] 1. bacteria expand training:

[0073] Example 1 constructed strains for the species L- isoleucine production were expanded by culturing a seed flask culture and tank culture two seeds, seed was obtained. in:

[0074] A medium for seed culture flask LB liquid medium; seed flask seed culture to a logarithmic phase, the bacteria solution was inoculated to a seed flask cultured seed tank two.

[0075] Media formulations secondary seed culture tank: KH 2 PO 4 1.5g / L, MgSO 4 · 7h 2 O 0.6g / L, (NH 4 ) 2 SO 4 2.25g / L, FeSO 4 · 7h 2 O 10mg / L, MnSO 4 · H 2 O 10mg / L, VB 1 0.3mg / L, glucose 50g / L, yeast extract powder 5g / L, betaine 0.225g / L, lysine 1g / L, methionine 1g / L; pH 7.5 ± 0.1.

[0076] Two seed tank culture conditions: temperature 32 ℃, pH6.8-7.0, 20-30% dissolved oxygen, the tank pressure 0.03MPa, flow rate 15L / min, stirring speed of 400 rpm; the inoculation amount was 10% (volume fraction), culture 10-12h.

[...

Embodiment 3

[0085] L- isoleucine production: Example 3

[0086] 1. bacteria expand training:

[0087] Example 1 strains were constructed by a seed flask cultures were expanded in culture and can be implemented two seeds, seed was obtained. in:

[0088] A medium for seed culture flask LB liquid medium; seed flask seed culture to a logarithmic phase, the bacteria solution was inoculated to a seed flask cultured seed tank two.

[0089] Media formulations secondary seed culture tank: KH 2 PO 4 1.5g / L, MgSO 4 · 7h 2 O 0.6g / L, (NH 4 ) 2 SO 4 2.25g / L, FeSO 4 · 7h 2 O 10mg / L, MnSO 4 · H 2 O 10mg / L, VB 1 0.3mg / L, glucose 50g / L, yeast extract powder 5g / L, betaine 0.225g / L, lysine 1g / L, methionine 1g / L; pH 7.5 ± 0.1.

[0090] Two seed tank culture conditions: temperature 32 ℃, pH6.8-7.0, 20-30% dissolved oxygen, the tank pressure 0.03MPa, flow rate 15L / min, stirring speed of 400 rpm; the inoculation amount was 10% (volume fraction), culture 10-12h.

[0091] 2. Fermentation:

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com