Groove chip embedding process

A chip and process technology, applied in the field of groove chip embedding process, can solve the problems of reducing the area of functional parts, uneven bottom, poor reliability, etc., and achieve the effect of improving bottom interconnection and heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The groove chip embedding process provided by this embodiment includes the following steps:

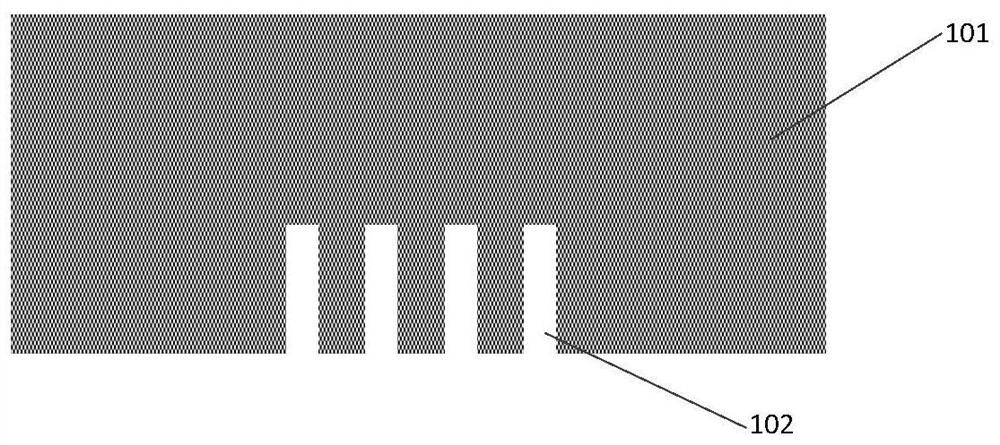

[0041] Such as figure 1 as shown,

[0042] (a), providing a silicon wafer, and etching a plurality of TSV holes on the surface of the silicon wafer to form a TSV region, then depositing a first passivation layer on the surface of the silicon wafer, and depositing at least one seed layer on the first passivation layer;

[0043] Fabricate TSV holes 102 on the surface of the base silicon wafer 101 by photolithography and etching process, the hole diameter ranges from 1um to 1000um, and the depth ranges from 10um to 1000um;

[0044] Deposit the first passivation layer such as silicon oxide or silicon nitride on the silicon wafer, or direct thermal oxidation, the thickness of the first passivation layer ranges from 10nm to 100um; by physical sputtering, magnetron sputtering or evaporation process Make a seed layer above the first passivation layer. The thickness of the seed layer ...

Embodiment 2

[0068] The groove chip embedding process provided by this embodiment includes the following steps:

[0069] Such as figure 1 as shown,

[0070] (a), providing a silicon wafer, and etching a plurality of TSV holes on the surface of the silicon wafer to form a TSV region, then depositing a first passivation layer on the surface of the silicon wafer, and depositing at least one seed layer on the first passivation layer;

[0071] Fabricate TSV holes 102 on the surface of the base silicon wafer 101 by photolithography and etching process, the hole diameter ranges from 1um to 1000um, and the depth ranges from 10um to 1000um;

[0072] Deposit the first passivation layer such as silicon oxide or silicon nitride on the silicon wafer, or direct thermal oxidation, the thickness of the first passivation layer ranges from 10nm to 100um; by physical sputtering, magnetron sputtering or evaporation process Make a seed layer above the first passivation layer. The thickness of the seed layer ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com