Preparation method of plasmon polariton enhanced quantum dot light emitting diode based on Au @ SiO2

A technology of quantum dot light emission and plasmon polaritons, which is applied in the manufacture of semiconductor/solid-state devices, electrical components, electric solid-state devices, etc. Turn-on voltage, novel preparation method, and the effect of improving luminous intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

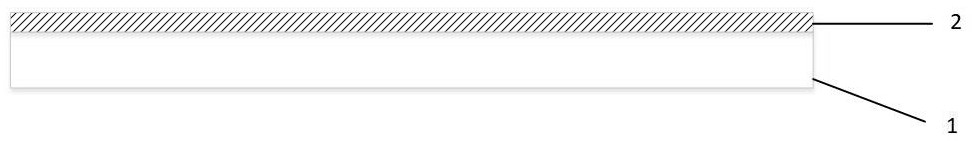

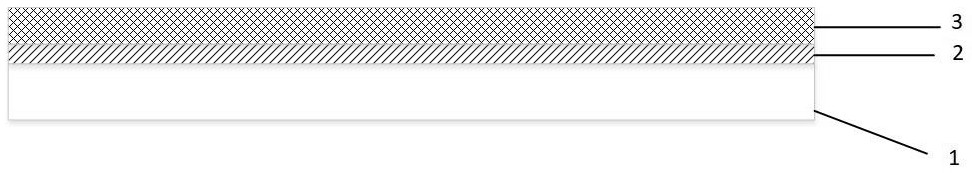

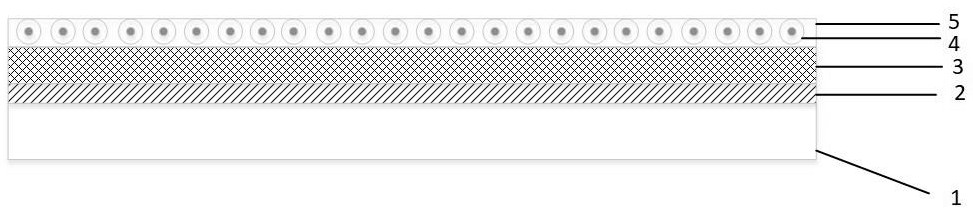

Image

Examples

Embodiment 1

[0047] (1) Weigh 0.0207g of cadmium oxide powder, 0.112g of 1-tetradecyl phosphoric acid and 2.0g of tri-n-butylphosphine oxide respectively, put them into a 50mL three-necked flask, first evacuate with argon for 30min, and then Heating to 240°C under protection to completely dissolve the solute to form a transparent solution, which is the cadmium precursor solution;

[0048] (2) Weigh 0.0316g of selenium powder and 1.0g of tributylphosphine respectively, put them into another 50mL three-necked flask, and then heat to 100°C under the protection of argon, so that the solute is completely dissolved to form a transparent solution, that is, selenium Precursor solution;

[0049] (3) At 250°C, quickly inject the selenium precursor solution into the cadmium precursor solution, then lower the temperature of the mixed solution to 220°C, and keep it warm for 1min, then remove the heat source, cool down to 80°C, and add 10 mg of organic matter Obtain CdSe quantum dot solution;

[0050]...

Embodiment 2

[0059] (1) Weigh 0.0614g of cadmium oxide powder, 0.336g of 1-tetradecyl phosphoric acid and 1.5g of tri-n-butylphosphine oxide respectively, put them into a 50mL three-necked flask, first evacuate with argon for 80min, and then Heating to 300°C under protection to completely dissolve the solute to form a transparent solution, which is the cadmium precursor solution;

[0060] (2) Weigh 0.0812g of selenium powder and 3.0g of tributylphosphine respectively, put them into another 50mL three-necked flask, and then heat them to 170°C under the protection of argon to completely dissolve the solute and form a transparent solution to obtain selenium Precursor solution;

[0061] (3) At 300°C, quickly inject the selenium precursor solution into the cadmium precursor solution, then lower the temperature of the mixed solution to 250°C, and keep it warm for 15 minutes, then remove the heat source, cool down to 100°C, and add 10 mg of organic matter Obtain CdSe quantum dot solution;

[00...

Embodiment 3

[0071] (1) Weigh 0.0608g of cadmium oxide powder, 0.326g of 1-tetradecyl phosphoric acid and 1.48g of tri-n-butylphosphine oxide respectively, put them into a 50mL three-necked flask, first evacuate with argon for 80min, and then Heating to 300°C under protection to completely dissolve the solute to form a transparent solution, which is the cadmium precursor solution;

[0072] (2) Weigh 0.0821g of selenium powder and 3.0g of tributylphosphine respectively, put them into another 50mL three-necked flask, and then heat them to 170°C under the protection of argon to completely dissolve the solute and form a transparent solution to obtain selenium Precursor solution;

[0073] (3) At 300°C, quickly inject the selenium precursor solution into the cadmium precursor solution, then lower the temperature of the mixed solution to 250°C, and keep it warm for 15 minutes, then remove the heat source, cool down to 100°C, and add 9 mg of organic matter Obtain CdSe quantum dot solution;

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com