Production method of ammonium vanadate

A production method and technology of ammonium vanadate, applied in chemical instruments and methods, vanadium compounds, improvement of process efficiency, etc., can solve problems such as reducing plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

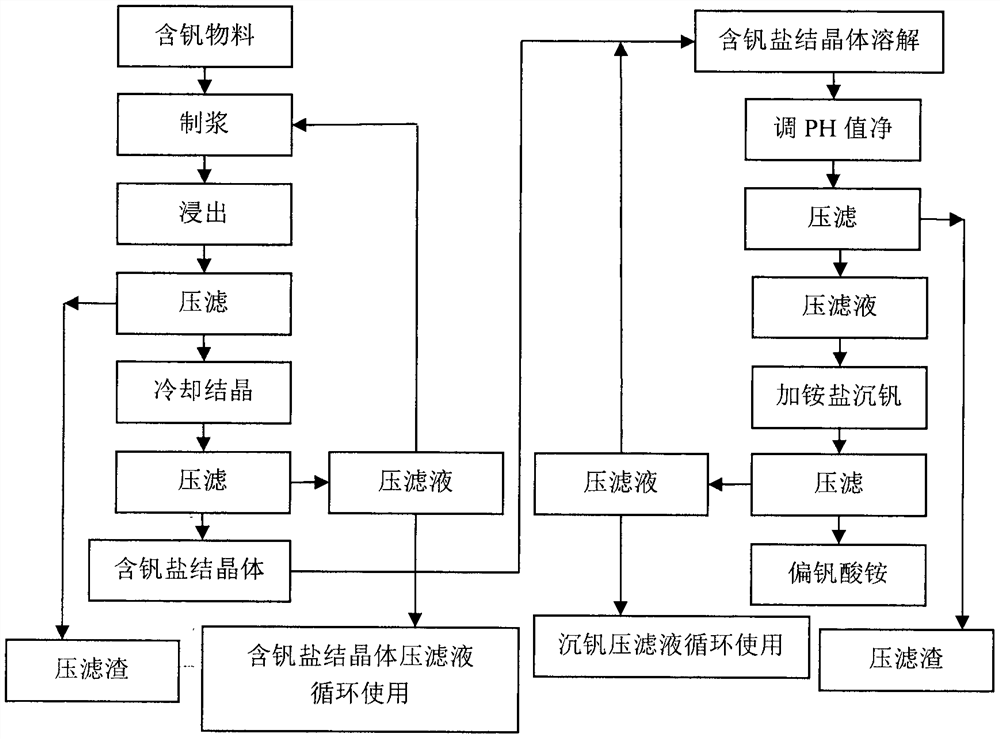

Method used

Image

Examples

Embodiment Construction

[0021] 1. Mix and stir the vanadium-containing material and slurrying solution to make slurry, the solid-to-liquid ratio is 1:2, and stir for 42 minutes. Preparation method of pulping liquid: add catalyst, oxidant, surfactant and defoamer to water. Stir for 42 minutes to dissolve. Catalysts are oxides, sulfides, etc., oxidants are sodium salts, potassium salts, manganese salts, ammonium salts, etc., surfactants are sulfonates, sodium salts, etc., defoamers are nitrates, phosphates, etc.

[0022] Sodium hydroxide or sodium carbonate and an oxidizing agent (such as hydrogen peroxide, manganese dioxide, sodium salt, potassium salt.) are added to the preparation water of the leach solution and stirred for 47 minutes to dissolve. The content of sodium hydroxide or sodium carbonate is 110g / L, and the content of oxidizing agent (such as hydrogen peroxide, manganese dioxide, sodium salt, potassium salt.) is 11g / L.

[0023] Stir and heat the prepared slurry of vanadium-containing mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com