Preparation method of high-conductivity graphene/copper composite wire

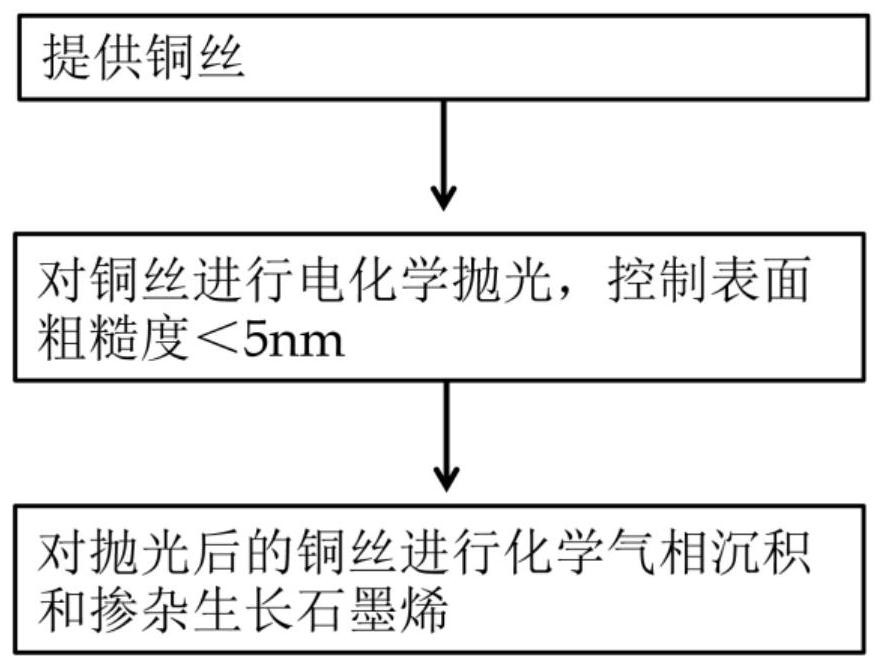

A composite wire and high conductivity technology, applied in the field of graphene/copper composite wire preparation, can solve the problems of lattice constant mismatch, affecting interface bonding strength, misfit dislocation at the interface, etc., to prolong growth time, crystal Effect of large particle size and reduction of nucleation density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Fabrication of single-cycle Gr / Cu wires

[0048] 1. The cold-drawn Cu wire with a diameter of 10 μm is electrochemically polished.

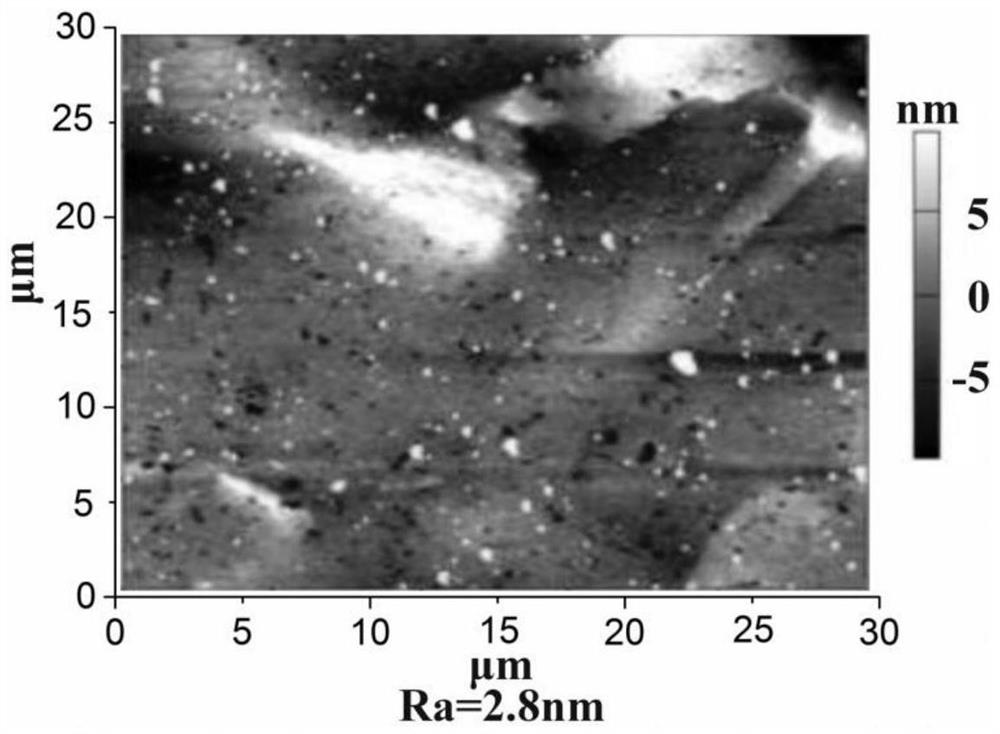

[0049] The electrochemical polishing solution is prepared by mixing and stirring 100mL deionized water, 50mL hydrochloric acid solution, 20mL alcohol, 5mL isopropanol and 2g urea. The Cu wire is immersed in a container filled with electrochemical polishing solution as an anode, and another piece of Cu sheet is used as a cathode. A 5V DC source provides constant voltage / current. The soaking time is 20s. Then the Cu wire was rinsed with deionized water and alcohol to remove the surface polishing solution, and then dried with nitrogen to obtain a Cu wire with a surface roughness of 2.8 nm.

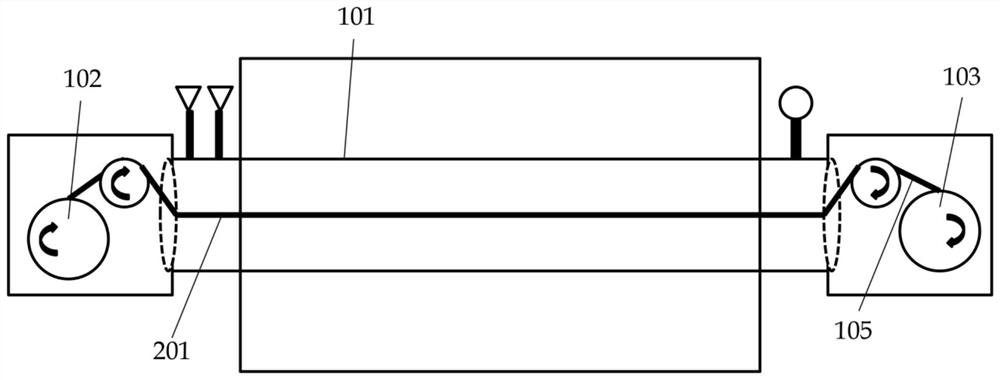

[0050] 2. A cyclic process of the deposition preparation including doped growth:

[0051] 2-1, the doping growth:

[0052] 2-1-1, the pre-treatment:

[0053] Send the electrochemically polished Cu wire into a tube furnace with a vacuum degree of 100...

Embodiment 2

[0060] Preparation of two-cycle Gr / Cu wire

[0061] 1. Electrochemical polishing of cold drawn copper wire

[0062] Repeat the cold drawn Cu electrochemical polishing step of Example 1, but the diameter of the Cu wire used is 30 μm, and the polishing solution is mixed with 100 mL deionized water, 40 mL phosphoric acid solution, 60 mL alcohol, 10 mL isopropanol and 2 g urea to obtain a rough surface Cu wire with a thickness of 3.8nm.

[0063] 2. A cyclic process of the Gr deposition preparation includes doping growth-etching:

[0064] 2-1, the doping growth:

[0065] 2-1-1, the pre-treatment:

[0066] Repeat the pretreatment step in embodiment one;

[0067] 2-1-2, the Gr doped growth:

[0068] Repeat the Gr-doped growth step of the embodiment, but wherein the growth temperature, pressure, carbon source (C 2 h 5 OH) flow, reducing gas flow, doping source (BH 2 ) The flow rate and constant temperature time are 1000°C, 500Torr, 8sccm, 200sccm, 5sccm and 30min respectively;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface roughness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com