Solid nano-powder composition containing nanoscale cannabidiol and preparation method and application of composition

A cannabidiol and composition technology, applied in the field of solid nano-powder compositions, can solve the problems of increasing the concentration of nano-suspension, difficult to obtain cannabidiol nano-crystals, small hydrophobic wetting coefficient, etc. Stability, precise and controllable nanoparticle size, and the effect of improving bioavailability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

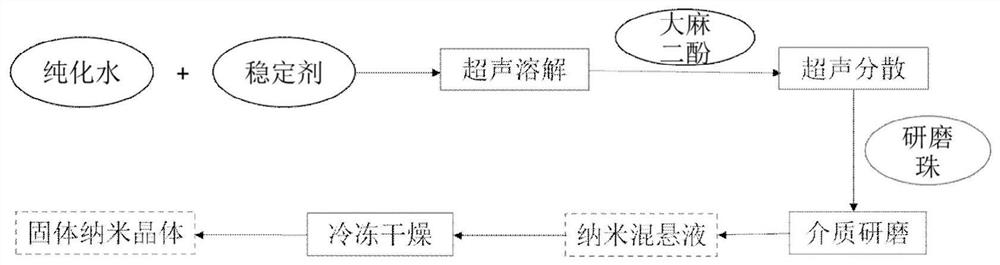

[0138] Embodiment 1 A kind of preparation of cannabidiol nanocrystal (media grinding method)

[0139] Weigh 6.25g of poloxamer P188, 0.375g of povidone K30, 0.125g of tert-butyl hydroxyanisole and 0.125g of citric acid, mix them to obtain a stabilizer, put them in a 250mL grinding jar, add 50mL of purified water, and ultrasonically To disperse, add D 90 12.5g of cannabidiol raw material with a diameter of 7 μm was dispersed by ultrasonic waves, 100g of zirconia grinding beads (0.2mm in diameter) were added, and the grinding tank was installed in a low-temperature planetary ball mill (model: QM-KD2, manufacturer: Nanjing Nanda Instrument Co., Ltd.) , control the grinding temperature to 10°C, and grind for 6 hours at a speed of 500rpm. After the grinding is completed, the cannabidiol nanocrystal suspension is obtained by separation, and the suspension is placed in a low-temperature freezer at -40°C for 12 hours. Dry in a dryer for 12 hours at a cold trap temperature of -40°C an...

Embodiment 2

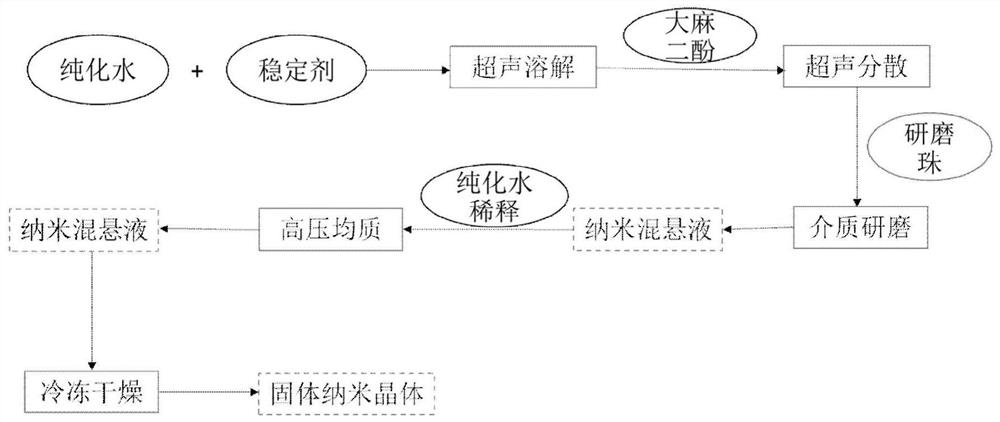

[0142] Embodiment 2 Preparation of a kind of cannabidiol nanocrystal (media grinding method)

[0143] Weigh the stabilizer containing 0.75g Cremphor RH40 (polyoxyethylene 40 hydrogenated castor oil), 0.125g microcrystalline cellulose and carmellose sodium copolymer (MCCS) and 0.0125g rosemary extract in a 250mL grinding jar Add 50mL of purified water, ultrasonically disperse, add D 902.5g of cannabidiol raw material with a diameter of 55 μm was dispersed by ultrasonic waves, 300g of zirconia grinding beads (0.5mm in diameter) were added, and the grinding tank was installed in a low-temperature planetary ball mill (model: QM-KD2, manufacturer: Nanjing Nanda Instrument Co., Ltd.) , control the grinding temperature to 10°C, and grind for 8 hours at a speed of 500rpm. After the grinding is completed, the cannabidiol nanocrystal suspension is obtained by separation. Dry in a dryer for 12 hours at a cold trap temperature of -40°C and a vacuum of 20 Pa to obtain solid nanocrystals o...

Embodiment 3

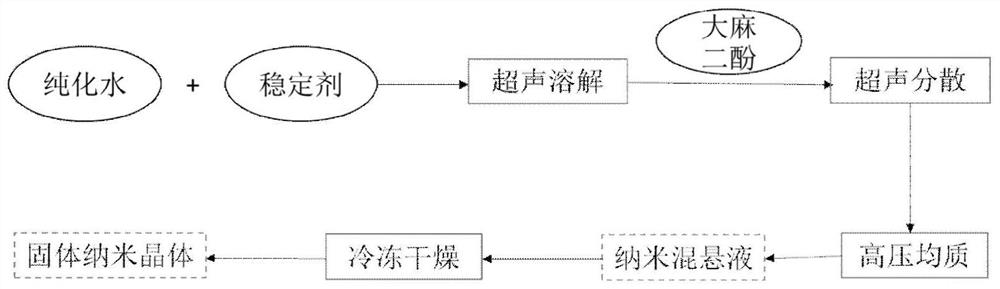

[0146] Example 3 Preparation of Cannabidiol Nanocrystals (High Pressure Homogenization Method)

[0147] Weigh the stabilizer containing 0.25g poloxamer P338, 0.02g hypromellose E4M and 0.03g tea polyphenols into a 250mL beaker, add 100mL purified water, ultrasonically disperse, add D 90 1g of cannabidiol raw material with a thickness of 7 μm was dispersed by ultrasonic waves, poured into the material cup of a high-pressure homogenizer (model: AH2010, manufacturer: ATS, Canada), and the homogenization temperature was controlled at 10°C. Cycle 5 times under 1000 bar pressure, and finally cycle 15 times under 1300 bar pressure to obtain cannabidiol nanocrystal suspension, freeze the suspension in a low-temperature freezer at -40°C for 12 hours, and place it in a freeze dryer. Dry for 18 hours under the conditions of cold trap temperature -40°C and vacuum degree of 20Pa to obtain cannabidiol solid nanocrystals.

[0148] Measure its average particle diameter and polydispersity ind...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com