A kind of cationic cyclodextrin-based hydrogel adsorption material and synthesis method thereof

A technology of adsorption materials and synthesis methods, which is applied in chemical instruments and methods, adsorption water/sewage treatment, water pollutants and other directions, can solve the problems of less research, less adsorption, ineffective effects, etc., and achieves a simple preparation process, Accessible, Inexpensive Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

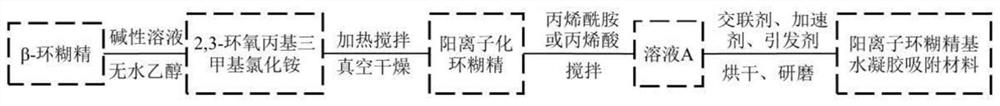

[0035] Dissolve 1g of β-cyclodextrin in 25ml of 0.8wt.% sodium hydroxide solution, stir until completely mixed, add 6.5g of 2,3-epoxypropyltrimethylammonium chloride to the solution, heat at 70°C Stir for 4 hours; vacuum dry to constant weight at 80°C to obtain β-cyclodextrin cationic derivative.

[0036] The obtained β-cyclodextrin cationic derivative was dissolved in 2.5 ml of water, 2.5 g of acrylamide was added, and the mixture was stirred at room temperature for 1 hour at a rotational speed of 500 rpm. Then add 0.2g cross-linking agent N,N'-methylenebisacrylamide (MBA), stir until the cross-linking agent MBA is completely dissolved, add 0.25mL accelerator N,N,N',N'-tetramethyl ethyl acetate Diamine (TEMED). When the above substances are mixed uniformly, add 5 mL of saturated potassium persulfate solution (KPS) solution of initiator, and stir at room temperature until hydrogel is formed. The resulting hydrogel was transferred to a glass bottle and immersed in deionized w...

Embodiment 2

[0039] Dissolve 1.5g of β-cyclodextrin in 25ml of 0.8wt.% sodium hydroxide solution, stir until completely mixed, add 10.5g of 2,3-epoxypropyltrimethylammonium chloride to the solution, heat for 70 Stir at °C for 4 hours; vacuum dry at 80 °C to constant weight to obtain β-cyclodextrin cationic derivative.

[0040] The obtained β-cyclodextrin cationic derivative was dissolved in 2.5 ml of water, 2.5 g of acrylic acid was added, and the mixture was stirred at room temperature for 1 hour at a rotational speed of 500 rpm. Then add 0.2g cross-linking agent N,N'-methylenebisacrylamide (MBA), stir until the cross-linking agent MBA is completely dissolved, add 0.25mL accelerator N,N,N',N'-tetramethyl ethyl acetate Diamine (TEMED). When the above substances are mixed evenly, add 5 mL of saturated ammonium persulfate solution (APS) solution of the initiator, and stir at room temperature until a hydrogel is formed. The resulting hydrogel was transferred to a glass bottle and immersed i...

Embodiment 3

[0043] Dissolve 1g of β-cyclodextrin in 25ml of 8wt.% sodium hydroxide solution, stir until completely mixed, add 10.5g of 2,3-epoxypropyltrimethylammonium chloride to the solution, heat at 70°C and stir 6 hours; vacuum drying at 80°C to constant weight to obtain β-cyclodextrin cationic derivatives.

[0044] The obtained β-cyclodextrin cationic derivative was dissolved in 2.5 ml of water, 1 g of acrylic acid was added, and the mixture was stirred at room temperature for 1 hour at a rotational speed of 500 rpm. Then add 0.2g cross-linking agent N,N'-methylenebisacrylamide (MBA), stir until the cross-linking agent MBA is completely dissolved, add 0.25mL accelerator N,N,N',N'-tetramethyl ethyl acetate Diamine (TEMED). When the above substances are mixed uniformly, add 5 mL of saturated potassium persulfate solution (KPS) solution of initiator, and stir at room temperature until hydrogel is formed. The resulting hydrogel was transferred to a glass bottle and immersed in deionize...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com