Amino and Fe (III) bifunctional spherical mesoporous silica adsorbing material and preparation method and application thereof

A technology of mesoporous silica and spherical silica, applied in chemical instruments and methods, adsorption of water/sewage treatment, alkali metal oxides/hydroxides, etc., can solve the problem of shortened adsorption equilibrium time and failure to achieve fast Requirements and other issues, to achieve excellent removal effect, fast adsorption speed, and good removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

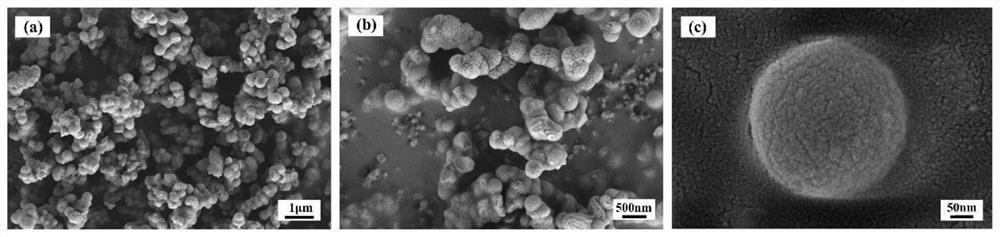

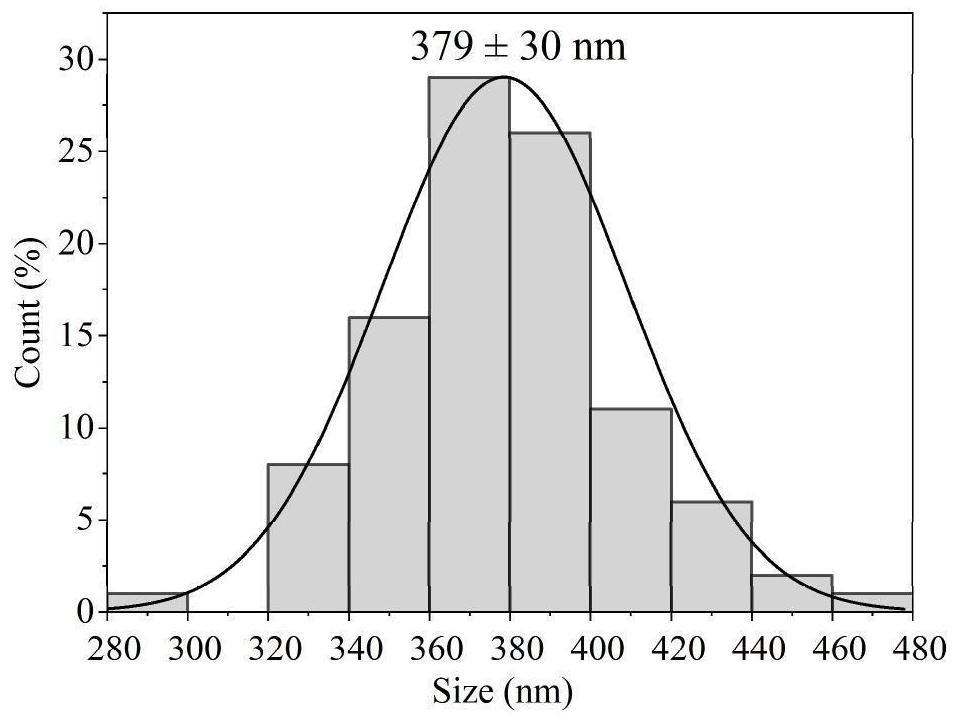

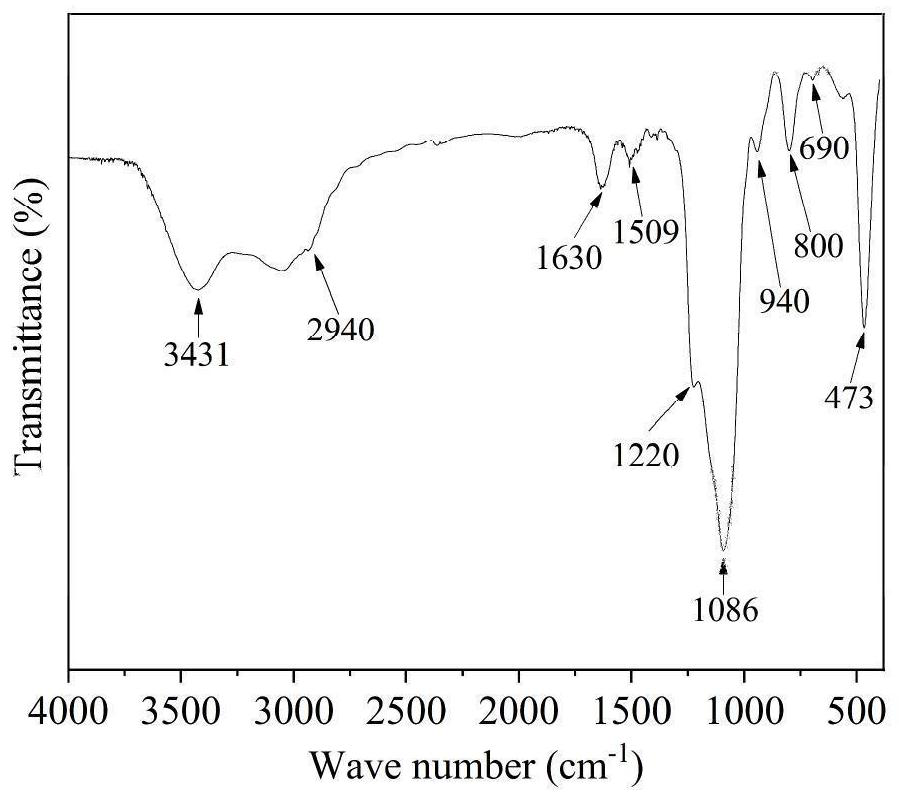

[0058] Preparation of Amino and Fe(III) Bifunctional Spherical Mesoporous Silica Submicron Composite

[0059] (1) Preparation of spherical silica: 160 mL of absolute ethanol (EtOH), 16 mL of concentrated ammonia water and 7 g of ethyl tetrasilicate were mixed and stirred at room temperature at 750-800 rpm for 20 h. After the reaction, the silica spheres were recovered and purified by multiple centrifugation and washed with absolute ethanol, dried at 70–80°C for 12 hours to constant weight, and ground into powder.

[0060] (2) Preparation of spherical mesoporous silica: the silicon spheres (0.352g) obtained in (1) were dispersed in EtOH (20.24mL), CTAB (0.4g), H 2 In the mixture of O (80mL) and NaOH (0.104g), stir at room temperature for 30min, the molar ratio of each component is 1SiO 2 :0.18CTAB:0.44NaOH:750H 2 O:75EtOH. Then the mixture was transferred to a polytetrafluoroethylene-lined hydrothermal reactor for hydrothermal reaction at a constant temperature of 100°C for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Maximum adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com